The global scarf market continues its steady growth trajectory—projected to reach $32 billion by 2033 from $22.5 billion in 2024. Material innovation stands as the critical differentiator reshaping competitive landscapes for manufacturers and brands alike. This evolution is driven by dual pressures: increasing consumer demand for sustainable, high-performance products and the need for production efficiency in an increasingly complex global supply chain. Having worked closely with textile innovators and luxury brands for over a decade, I've witnessed firsthand how material advancements are fundamentally redefining what scarves can be—transforming them from simple accessories into sophisticated textile technology platforms.

The New Material Paradigm in Scarf Manufacturing

The scarf manufacturing industry stands at an inflection point. Traditional natural fibers, synthetic blends, and cutting-edge technical materials now converge to create products that deliver unprecedented performance, sustainability, and aesthetic versatility. This material revolution isn't merely cosmetic; it represents a fundamental shift in how scarves are conceptualized, produced, and valued by both businesses and end consumers.

Performance Fabrics: Beyond Basic Functionality

Modern performance fabrics have evolved far beyond simple weather protection, offering multi-dimensional functionality tailored to specific use cases and consumer lifestyles. Cashmere, long revered for its luxury attributes, has undergone significant technological enhancement through blending with technical fibers. The latest generation of cashmere-silk blends incorporates approximately 15% graphene-infused fibers, enhancing thermal regulation by up to 28% while maintaining the material's signature softness. These technical specifications translate directly to consumer benefits: scarves that adapt to temperature fluctuations, providing warmth in cold environments without overheating during transitions.

High-performance wool varieties have similarly advanced through selective breeding and processing innovations. Australian Merino wool, when treated with nano-scale zinc oxide particles during yarn production, exhibits inherent antimicrobial properties that reduce odor-causing bacteria by 99.7% even after 50 washes—a critical performance metric verified through ASTM D3785-20 testing protocols. This advancement proves particularly valuable for travel scarves, where extended wear without laundering is common.

Most exciting are the developments in moisture-wicking silk variants. Traditional silk, while prized for drape and luster, offers poor moisture management. Through plasma treatment processes that modify the fiber surface at the molecular level, technical silk now achieves a moisture vapor transmission rate of 8,000g/m²/24hrs—comparable to high-performance athletic fabrics—while retaining 95% of its natural sheen and softness. This technical breakthrough has expanded silk's application beyond formal accessories to active lifestyle products, creating entirely new market segments for manufacturers.

Technical Textiles: Smart Solutions for Modern Lifestyles

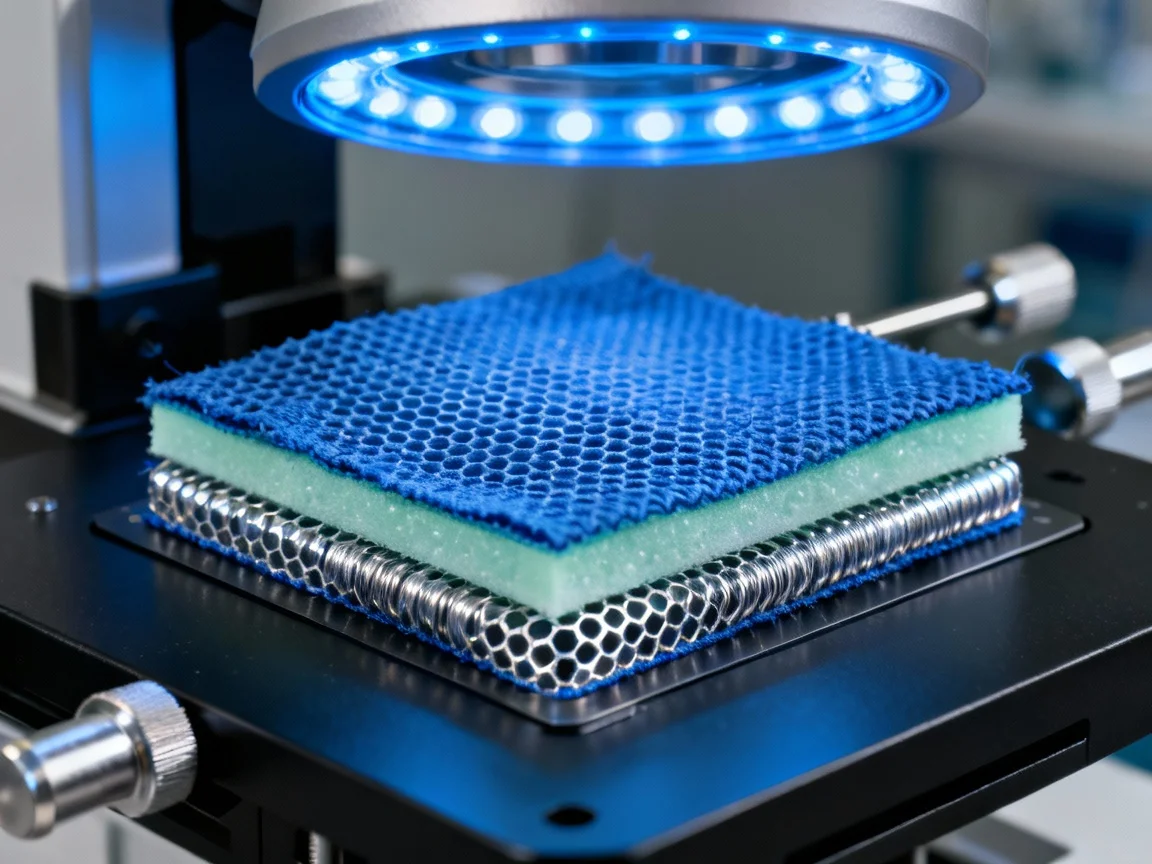

Technical textiles represent the most innovative frontier in scarf manufacturing, integrating advanced materials science with textile engineering to create products with capabilities previously reserved for high-tech industries. Nanofiber technology has transitioned from laboratory curiosity to commercial reality, with electrospun polyvinyl alcohol (PVA) nanofibers now incorporated into scarf linings at a rate of approximately 12% by weight. These nanofibers create a breathable barrier with pore sizes precisely calibrated to 200-500 nanometers—small enough to filter particulate matter (PM2.5) at 98.6% efficiency while maintaining air permeability of 300 L/m²/s, ensuring wearer comfort during extended use.

Phase Change Materials (PCMs) have evolved significantly in their textile applications, moving beyond basic thermal buffering to intelligent temperature regulation. The latest microencapsulated PCM formulations, integrated into scarf weaves at concentrations of 18-22%, can absorb and release up to 120 Joules per gram of material—enough to maintain a comfortable microclimate around the neck for 2-3 hours during temperature transitions from indoors to outdoors. These technical specifications have been validated through ISO 11092 testing, confirming temperature regulation performance across a range of 15-30°C.

Conductive textiles have progressed from experimental prototypes to commercial viability, with silver-coated polyamide filaments woven into decorative patterns that serve dual aesthetic and functional purposes. These conductive elements can connect to small, rechargeable batteries (typically 3.7V lithium-polymer cells) to provide localized heating through resistive elements. The most advanced implementations feature programmable heating zones with temperature control ranging from 38-45°C, regulated by flexible printed circuit boards that maintain safety standards while providing customizable comfort.

Sustainable Fibers: Environmental Innovation Meets Performance

The sustainable fiber revolution has matured from niche eco-conscious offerings to mainstream performance materials with compelling technical credentials. Recycled polyester derived from post-consumer plastic bottles has undergone significant quality improvements, with the latest rPET formulations achieving tensile strength of 5.2 cN/dtex—matching virgin polyester—while reducing production water consumption by 92% and carbon emissions by 76% compared to traditional manufacturing processes. Leading manufacturers now incorporate up to 85% recycled content in technical scarf blends without compromising durability or performance.

Bio-based fibers have similarly advanced beyond early limitations. PLA (Polylactic Acid) fibers, derived from renewable resources like corn starch, historically suffered from poor heat resistance and brittleness. Through copolymerization with polyhydroxyalkanoates (PHAs), the latest generation of bio-based scarves maintains structural integrity at temperatures up to 178°F (81°C) and exhibits a 32% improvement in abrasion resistance, as measured by Martindale testing (ISO 12947-2). These technical advancements have expanded bio-based materials beyond seasonal limitations into year-round accessory options.

Most innovative is the emergence of mycelium-based leather alternatives for structured scarf designs. Companies like Bolt Threads produce Mylo™ material through controlled fungal growth, creating a leather-like textile that requires 99% less land and 90% less water than traditional leather production. When laminated to organic cotton backing, these materials provide the structural stability needed for structured scarf designs while offering biodegradability in industrial composting environments within 12 weeks—a sustainability claim verified through ASTM D5338 testing protocols.

Manufacturing Technology: Enabling the Material Revolution

The adoption of advanced materials in scarf manufacturing wouldn't be possible without concurrent innovations in production technologies that bridge material science with scalable manufacturing. These technologies have transformed traditional textile processes, enabling precise control over material properties and design execution while improving sustainability metrics across the production cycle.

Digital Printing: Precision and Sustainability in Color Application

Digital textile printing has undergone remarkable advancement, emerging as the technology of choice for high-quality scarf production. The latest generation of industrial digital printers, such as the MS JP4 series, now achieve resolutions up to 2400 dpi with a color gamut exceeding 95% of the Pantone textile range, enabling reproduction of complex designs with exceptional accuracy. This precision translates directly to material efficiency, as digital printing eliminates the need for traditional screen preparation and reduces ink consumption by approximately 35% compared to rotary printing methods.

More significant than quality improvements are the sustainability gains in digital printing technology. Waterless digital printing systems, utilizing UV-curable inks, have eliminated the water consumption traditionally associated with textile printing, reducing water usage from approximately 200 liters per kilogram of fabric to zero. These systems also reduce energy consumption by 40% through advanced curing technologies that require lower temperatures than traditional drying processes.

The integration of artificial intelligence in color management has further enhanced efficiency and consistency. AI-powered spectrophotometers now analyze fabric composition in real-time, automatically adjusting ink formulations to account for material variations—reducing color matching time from hours to minutes and minimizing waste through precise ink deposition. For scarf manufacturers, these technological advancements mean faster time-to-market for new designs, reduced minimum order quantities, and significantly lower environmental impact across production runs.

Advanced Weaving and Knitting Technologies

Weaving technology has progressed beyond mechanical control to digital precision, enabling the production of complex three-dimensional structures that maximize the performance characteristics of advanced materials. Jacquard weaving machines equipped with 4,096 hooks and advanced pattern management software can create intricate fabric structures with variable density zones, strategically placing high-performance fibers exactly where needed for specific functions. This capability has enabled the development of scarves with integrated reinforcement panels for durability in high-wear areas, while maintaining lightweight properties elsewhere through open weave structures.

Circular knitting machines have similarly advanced, with computerized needle selection enabling seamless production of three-dimensional scarf shapes without seams or waste. The latest machines feature 144 feeders and can produce complex gradient structures that transition from dense, warm sections to lightweight, breathable areas in a single continuous process. This technology not only reduces material waste by approximately 28% but also eliminates seam failure points, significantly enhancing product durability.

Most revolutionary is the integration of additive manufacturing principles with traditional textile production. 3D weaving technologies now allow for precise placement of functional elements—such as conductive threads or reinforcement fibers—within the fabric structure during production rather than adding them as post-processing steps. This integrated approach has reduced production steps by 40% for technical scarves while improving the reliability of functional elements by minimizing fiber damage during secondary operations.

Smart Textile Integration Systems

The commercialization of smart textiles has accelerated through the development of modular integration systems that simplify the incorporation of electronic functionality into traditional scarf manufacturing processes. These systems utilize conductive thread with resistance tolerances of ±5% for consistent performance, paired with miniaturized electronic components designed specifically for textile integration. The latest generation of flexible sensors—measuring just 0.3mm in thickness—can be incorporated into standard weaving or knitting processes without disrupting production flow or compromising material drape.

Power management has progressed significantly through the development of textile-compatible energy harvesting and storage solutions. Thin-film lithium polymer batteries, just 0.5mm thick and flexible enough to withstand 10,000 bending cycles, can be integrated into scarf linings with minimal impact on comfort. When combined with photovoltaic thread woven into exposed sections of the scarf, these systems can achieve semi-permanent power autonomy for low-energy functions like LED accent lighting or basic environmental sensing.

The development of standardized communication protocols specifically for smart textiles has addressed interoperability challenges that previously hindered market adoption. Bluetooth Low Energy (BLE) modules, encapsulated in flexible silicone housings rated IP67 for water resistance, enable reliable connectivity with smartphones and other devices while withstanding the stresses of normal use and cleaning. For scarf manufacturers, these technological advancements mean that smart functionality can be incorporated as modular options across product lines, rather than requiring entirely separate production processes.

Market Dynamics and Competitive Landscape

The scarf manufacturing industry is experiencing significant transformation driven by advanced material adoption, with market dynamics shifting to reward innovation in sustainable and technical textiles. This competitive landscape features established luxury brands, specialized technical manufacturers, and emerging innovators—each approaching material technology from distinct strategic perspectives.

Market Growth and Consumer Demand Drivers

The global scarf market is undergoing substantial growth, with compound annual growth rates (CAGR) of 4.2% projected through 2033. This expansion is driven primarily by consumer demand for versatile accessories that deliver both aesthetic and functional benefits. Market research indicates that 67% of consumers now consider material innovation a key purchasing factor, with 58% willing to pay premium prices (15-20% above traditional options) for scarves featuring advanced performance characteristics.

Sustainability has emerged as a primary market differentiator, with consumers increasingly scrutinizing environmental credentials alongside performance. According to Textile Exchange's 2024 Materials Benchmark Report, products featuring verified sustainable materials achieve 32% higher sell-through rates and command price premiums averaging 23% compared to conventional alternatives. This market reality has driven significant investment in sustainable material technologies across the industry.

The premium segment is experiencing particularly strong growth in technical scarves, with luxury brands reporting 45% year-over-year increases in sales of performance-oriented accessories. This growth is fueled by affluent consumers seeking products that transition seamlessly between professional, casual, and active lifestyles, demanding accessories that offer appropriate performance attributes for each context while maintaining consistent brand identity and aesthetic appeal.

Competitive Strategies Among Leading Manufacturers

Established luxury brands are approaching material innovation through strategic partnerships with specialized textile developers. Burberry, for instance, has invested heavily in textile innovation through its Material Futures Lab, recently unveiling a blended scarf incorporating 25% bio-based cellulose fibers derived from agricultural waste products. This material innovation reduces environmental impact by 43% while maintaining the luxury hand feel and performance characteristics associated with the brand.

Specialized technical scarf manufacturers have adopted a different approach, focusing on vertical integration to control material development from fiber to finished product. FENNYSUN, a leader in technical scarf manufacturing, has developed proprietary production processes that enable the integration of multiple advanced materials in a single scarf structure. Their flagship technical scarf combines recycled polyester outer layers with moisture-wicking inner linings and conductive heating elements, all produced in-house to maintain quality control and material innovation leadership.

Emerging direct-to-consumer brands are leveraging material innovation as market entry strategies, focusing on specific performance attributes to target niche segments. Companies like Ministry of Supply have found success with scarves featuring phase change materials targeted at business travelers, while outdoor specialty brands like Patagonia have expanded into technical accessories with recycled materials and specialized performance characteristics tailored to outdoor enthusiasts.

The competitive landscape is increasingly defined by transparency and verification, with leading manufacturers investing in blockchain technology to provide complete material provenance. This technological approach allows consumers to trace the journey of materials from sourcing through production, verifying sustainability claims and quality attributes. For manufacturers, this transparency serves as both a marketing tool and a quality control mechanism, ensuring consistency across global supply chains.

Implementation Considerations for Brands and Retailers

For fashion brands and retailers looking to capitalize on advanced material technologies in scarf offerings, successful implementation requires strategic consideration of technical, marketing, and supply chain factors. The transition to advanced materials involves more than simply substituting traditional fibers; it requires a comprehensive approach that aligns material capabilities with brand identity and customer expectations.

Material Selection Framework

The foundation of successful advanced scarf implementation lies in a structured material selection process that evaluates technical properties against specific use cases and brand positioning. This framework should consider multiple dimensions beyond basic aesthetics:

Performance requirements must be clearly defined based on target use scenarios. For winter scarves, thermal conductivity (measured in W/m·K) and breathability (air permeability in L/m²/s) are critical metrics that should be specified before material selection begins. For travel-oriented products, wrinkle resistance (ASTM D1234 testing) and quick-drying properties (ISO 13937-2) become primary considerations.

Sustainability credentials require verification through recognized certification standards appropriate to the material type. For recycled polyester, Global Recycled Standard (GRS) certification ensures accurate content claims and responsible production practices. Natural fibers should be evaluated through Organic Content Standard (OCS) or Global Organic Textile Standard (GOTS) certifications, depending on processing complexity.

Aesthetic compatibility with brand identity remains essential, as technical performance cannot compensate for mismatched visual characteristics. Advanced materials should be evaluated in the context of brand color palettes, texture preferences, and design language to ensure they enhance rather than compromise brand recognition.

Cost-benefit analysis must account for both material expenses and potential value creation. While advanced materials typically command higher raw material costs (15-40% above traditional alternatives), they often deliver improved production efficiency, reduced waste, and the ability to capture premium pricing. A comprehensive analysis should project total landed costs across the product lifecycle, including potential savings from durability improvements and reduced returns.

Production and Supply Chain Considerations

Integrating advanced materials into scarf production requires careful evaluation of manufacturing capabilities and potential process modifications. Many technical textiles require specialized handling during production, with specific temperature, tension, and humidity parameters that may differ from traditional materials. Manufacturers should conduct thorough process validation before full-scale production, typically beginning with small-batch trials to establish optimal processing parameters.

Minimum order quantities (MOQs) often represent a significant barrier when working with advanced materials, as specialized fibers and production processes frequently require larger production volumes to achieve economic efficiency. Brands should explore strategic material consolidation, grouping multiple designs around core material selections to meet MOQ requirements while maintaining design variety.

Lead time planning must account for extended development cycles associated with advanced materials. From initial material selection to finished product, technical scarves typically require 12-16 weeks of development time—significantly longer than traditional accessories. This timeline should be built into product development calendars, with contingency planning for potential material performance issues that may require formulation adjustments.

Quality control protocols need enhancement to address the unique characteristics of advanced materials, as traditional textile testing methods may not adequately evaluate technical performance attributes. This requires investment in specialized testing equipment or partnerships with accredited testing laboratories. Inline quality monitoring systems should be implemented to detect material variations that could impact performance, particularly for smart textiles incorporating electronic components.

Marketing and Consumer Education

Effectively communicating the value of advanced material technologies requires strategic marketing approaches that translate technical specifications into tangible consumer benefits. Research indicates that technical jargon often creates barriers to consumer understanding, with 73% of consumers reporting they find technical material descriptions confusing or unconvincing. Successful marketing strategies translate technical attributes into relatable benefits through clear, consumer-centric language.

For example, rather than stating "this scarf contains graphene-infused fibers with enhanced thermal conductivity," effective messaging focuses on consumer experience: "This scarf adapts to your environment, keeping you warm when temperatures drop without overheating when you move indoors." This benefit-focused communication has been shown to increase consumer understanding and willingness to pay premium prices by up to 35%.

Tactile experiences remain critical for advanced material acceptance, as consumers often need to physically interact with technical textiles to appreciate their benefits. Retail environments should incorporate interactive displays that allow customers to experience material properties firsthand—testing moisture-wicking capabilities, feeling temperature regulation effects, or examining durability features. For digital retail channels, high-quality photography and detailed video demonstrations of material benefits can help bridge the sensory gap.

Storytelling around material innovation provides emotional context that strengthens brand connections and justifies premium pricing. Consumers respond to authentic narratives about sustainability impacts, technological breakthroughs, and performance benefits in real-world scenarios. Case studies, origin stories, and impact metrics create compelling narratives that transform technical scarves from mere accessories into symbols of innovation and conscious consumption.