As a textile printing specialist with over 15 years of industry experience, I've witnessed firsthand how digital transformation has revolutionized scarf manufacturing. Market analysis indicates the global digital textile printing sector is poised for remarkable growth, projected to expand from $3.89 billion in 2025 to $12.73 billion by 2034. This exponential growth is primarily driven by increasing demand for customization and sustainable production methods. Among industry pioneers leading this digital revolution, FENNYSUN has distinguished itself through five groundbreaking innovations implemented in 2023. These cutting-edge solutions directly address the evolving needs of boutiques, specialty retailers, and fashion brands worldwide.

The Digital Revolution in Scarf Manufacturing

The textile industry has long grappled with balancing creative expression and production efficiency—until digital printing technology fundamentally transformed this equation. Traditional screen printing demanded substantial setup costs and lengthy production runs, rendering customization and small-batch production economically unviable. Today, shifting ordering patterns, evolving consumer preferences, and growing sustainability concerns have collectively fueled the adoption of digital print solutions, creating an unprecedented paradigm shift in manufacturing practices.

FENNYSUN recognized this industry transformation early. With over three decades of experience as a professional scarf manufacturer, the company has made significant investments in digital transformation. Founded in 1995, FENNYSUN successfully transitioned from conventional production methodologies to emerge as a leader in digital textile printing. The company has seamlessly integrated manufacturing, design, and sales into a cohesive workflow that maintains thousands of ready-to-ship styles while offering exceptional flexibility for custom orders.

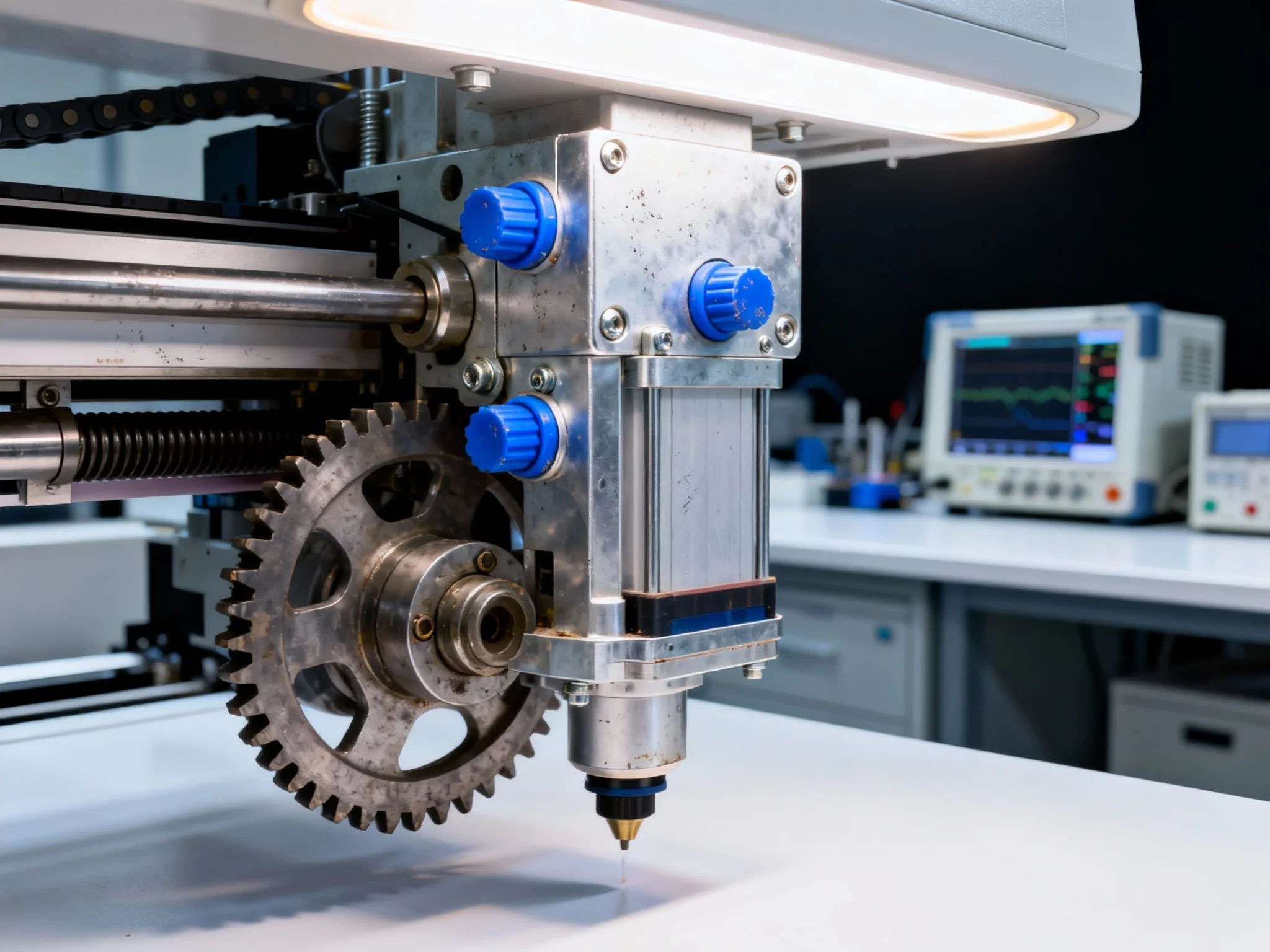

Innovation 1: Advanced Digital Printing Workflow Integration

At the core of FENNYSUN's 2023 innovations lies a fully integrated digital workflow spanning from initial design concept to final production. This end-to-end digital ecosystem eliminates traditional manufacturing bottlenecks and substantially reduces production lead times. Unlike competitors operating with fragmented systems, FENNYSUN's integrated approach enables real-time design modifications and instant production scheduling adjustments.

The measurable benefits of this integrated workflow are substantial: setup times have been reduced by up to 70% compared to traditional manufacturing methods. This dramatic improvement enables more frequent design iterations and faster responses to evolving market trends—critical advantages in fashion's fast-paced environment where seasonal demands and consumer preferences shift rapidly.

What truly distinguishes FENNYSUN is how this digital integration extends to customer-facing processes. Retail partners gain access to an intuitive digital platform that allows them to preview designs, make modifications, and place orders while maintaining full visibility of production timelines. This unprecedented transparency builds trust and streamlines the traditionally complex wholesale ordering process.

Innovation 2: Eco-Friendly Printing Solutions for Sustainable Fashion

Sustainability has evolved from a niche concern to a critical differentiator in textile manufacturing. FENNYSUN's 2023 innovations place environmental responsibility at the forefront of its production philosophy, implementing a comprehensive sustainability program that addresses both materials selection and manufacturing processes.

Digital printing inherently offers environmental advantages over traditional methods by eliminating water-intensive color mixing and reducing chemical usage. FENNYSUN has expanded these benefits by investing in advanced water-based, eco-friendly inks that meet the strictest global standards for harmful substances while delivering exceptional color vibrancy and longevity.

The company's commitment to sustainable materials is equally impressive. In 2023, FENNYSUN significantly expanded its sustainable fabric offerings to include organic silk, recycled polyester, and other eco-conscious materials. Importantly, these environmentally responsible choices do not compromise quality or aesthetic appeal, enabling fashion brands to meet their environmental commitments while still offering luxury accessories to discerning customers.

FENNYSUN's waste reduction program demonstrates particular innovation. By optimizing digital printing processes and implementing precision cutting techniques, the company has reduced fabric waste by approximately 35% compared to industry averages. This achievement not only reduces environmental impact but also improves cost efficiency—a genuine win-win scenario demonstrating how sustainability and profitability can align harmoniously.

Innovation 3: High-Resolution Printing Technology for Luxury Scarves

In the luxury scarf market, detail and color accuracy are paramount. FENNYSUN's 2023 investment in state-of-the-art high-resolution digital printing technology has established new industry benchmarks for print quality. The company's advanced digital printers deliver exceptional resolution capabilities that capture intricate designs with remarkable clarity, bringing artistic visions to life with precise detail reproduction.

This technology particularly excels at rendering complex patterns and gradient transitions—areas where traditional printing often struggles with achieving smooth color transitions and preserving fine details. FENNYSUN's digital printing technology handles these challenges with ease, resulting in scarf designs that maintain their integrity even when scaled to different sizes.

Complementing this high-resolution technology is a sophisticated color management system that ensures consistent color reproduction across production runs and different fabric types. For brand identity preservation, this consistency is crucial—enabling fashion houses to maintain precise color standards across their accessory lines.

FENNYSUN's technology demonstrates exceptional versatility across diverse luxury materials, from delicate silk to textured wool. Maintaining superior print quality across this range of substrates provides designers with unprecedented creative freedom while allowing FENNYSUN to serve diverse customer needs through a single, sophisticated production process.

Innovation 4: Custom Digital Scarf Printing Platform for On-Demand Production

The rising demand for personalized fashion has created a need for more flexible production capabilities. FENNYSUN's 2023 customization platform directly addresses this market requirement with an innovative system that enables brands to create custom scarf designs with minimal setup costs and shorter production runs than traditionally possible. This breakthrough opens new possibilities for limited-edition collections and personalized customer offerings.

The platform seamlessly integrates intuitive design tools with FENNYSUN's production systems, allowing brands to preview designs on different fabrics in real time while receiving accurate production timelines and cost estimates. This transparency empowers informed decision-making without the traditional guesswork associated with custom manufacturing.

What truly distinguishes this platform is its remarkable balance of flexibility and efficiency. While some manufacturers offer customization at the expense of production speed, FENNYSUN's digital workflow moves custom designs from approval to production in a fraction of the time required by conventional methods. This efficiency makes small-batch customization economically viable for brands of all sizes.

The platform also incorporates sophisticated color matching capabilities that ensure custom designs maintain brand color consistency—a critical feature for fashion brands with established color palettes. This eliminates the common frustration of color variation between production runs and product categories.

Innovation 5: Smart Inventory and Supply Chain Management Systems

Beyond production innovations, FENNYSUN has transformed inventory and supply chain management for scarf manufacturers. The company's 2023 implementation of smart inventory management leverages digital printing's inherent flexibility to reduce stock levels while maintaining product availability—a critical advantage in an industry where overstocking causes significant waste and profit-eroding markdowns.

By combining real-time sales data with advanced predictive analytics, FENNYSUN optimizes production schedules to more accurately match demand patterns. This data-driven approach minimizes large inventory holdings while ensuring popular designs remain in stock. For wholesale partners, this translates to reduced lead times and the ability to respond quickly to sales trends without requiring large initial orders.

The integration of smart inventory with digital printing creates a virtuous cycle: real-time sales data identifies emerging trends, digital production rapidly addresses these demands, and this information feeds into more accurate demand forecasting. This agility enables FENNYSUN's retail partners to capitalize on trends faster than competitors constrained by traditional production and inventory models.

Most importantly, this approach significantly reduces supply chain waste. Producing closer to actual demand minimizes overproduction—the fashion industry's single largest environmental impact factor. This lean manufacturing approach aligns with both economic and environmental sustainability goals, demonstrating FENNYSUN's comprehensive commitment to responsible production practices.

Implementation Considerations for Fashion Brands

Fashion brands considering a digital scarf printing partner like FENNYSUN should keep several key considerations in mind to maximize value from the relationship. First, brands should thoroughly understand the full range of customization capabilities and how they align with specific brand needs. Digital printing offers unprecedented design freedom, but effective utilization requires adjusting from traditional design approaches.

When developing designs specifically for digital printing, brands should consider the technology's unique capabilities. They should take full advantage of high resolution by incorporating finer details than traditional methods allow while experimenting with gradient transitions and complex color combinations that showcase the technology's strengths.

Sustainability should serve as a guiding principle in material selection. FENNYSUN's eco-friendly fabrics and inks enable brands to create luxury accessories with reduced environmental impact. When evaluating manufacturers, brands should inquire about specific sustainability metrics and certifications—transparency in these areas indicates genuine commitment versus superficial greenwashing.

Finally, brands should leverage the data capabilities of digital production by working closely with manufacturing partners to understand sales trends and optimize production schedules accordingly. The ability to rapidly respond to emerging trends with limited production runs creates significant competitive advantage in today's fast-paced fashion landscape.

The Evolving Landscape of Digital Scarf Printing

Looking beyond 2023, the future of digital textile printing appears exceptionally promising. As technology continues to advance, we can anticipate even higher resolution capabilities, more efficient production processes, and expanded material compatibility. FENNYSUN's ongoing commitment to innovation positions the company well to incorporate these advancements as they emerge.

AI integration into design and production workflows shows particular promise. AI-assisted design tools could identify emerging patterns and color trends, providing data-driven insights while preserving creative control. In production, AI optimization could further reduce waste and energy consumption, moving the industry closer to truly sustainable manufacturing practices.

E-commerce growth will likely drive further innovation in digital textile printing. As direct-to-consumer models expand, demand for personalized, made-to-order accessories will increase, requiring even more flexible production capabilities than currently available.

For fashion brands, the strategic message is clear: partnering with leading digital printing manufacturers is no longer optional but essential for maintaining competitiveness. FENNYSUN's 2023 innovations demonstrate a deep understanding of this new landscape and a commitment to providing the capabilities brands need to succeed in fashion's digital age.

As the industry continues to evolve, successful brands will embrace these technological advancements while maintaining their creative vision and sustainability commitments. In this rapidly changing environment, manufacturers like FENNYSUN that combine technical innovation with industry expertise will shape the future of fashion accessories production.