As the digital textile printing market expands at an unprecedented rate—projected to reach $19.44 billion by 2025—scarf manufacturing stands at the forefront of this technological revolution. For fashion manufacturers, boutiques, and specialty retailers, understanding digital printing technology has transitioned from an advantage to an essential business requirement in today's competitive landscape.

This comprehensive analysis, informed by extensive experience with luxury scarf manufacturers and digital printing technology providers, cuts through industry hype to deliver actionable insights on the trends transforming digital scarf production. We examine the technological advancements driving market growth, sustainability innovations reshaping production practices, and strategic considerations for selecting partners in this rapidly evolving sector.

Technological Advancements Revolutionizing Digital Scarf Printing

The landscape of digital scarf printing has undergone a remarkable transformation in recent years, driven by significant hardware and software innovations. The 2024 ITMA exhibition showcased industry-leading advancements that are fundamentally redefining production capabilities for fashion accessories.

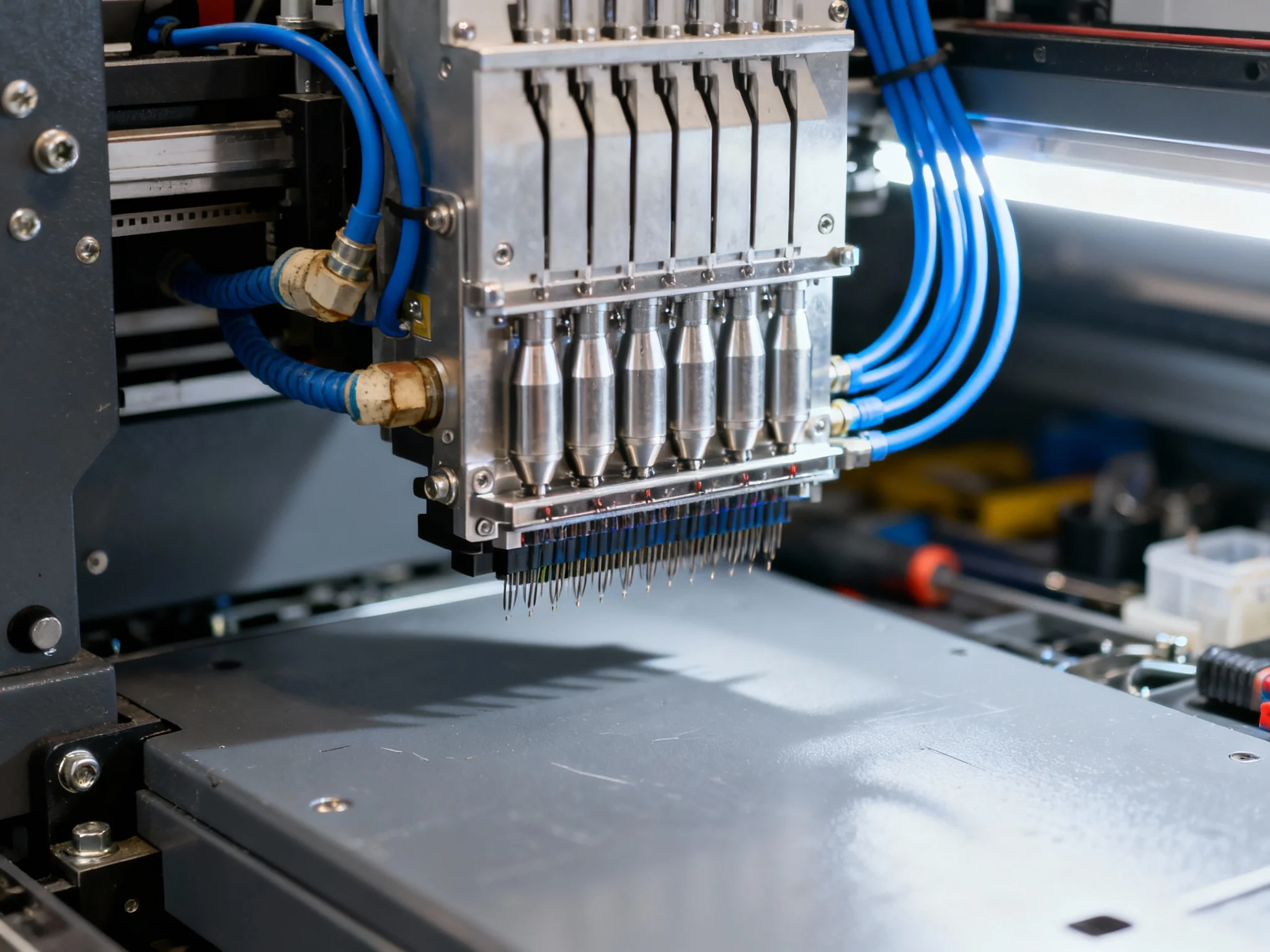

High-Speed Production Systems have emerged as critical differentiators for manufacturers balancing quality and operational efficiency. Japan's Epson Monna Lisa series exemplifies the industry's technical direction, featuring precision print heads capable of 1440 dpi resolution. These advanced systems deliver production speeds that seemed unimaginable just five years ago, with certain models now matching traditional screen printing output rates for medium-volume runs while maintaining superior design fidelity.

Ink Technology Innovations represent another transformative aspect of modern digital scarf printing, particularly for sustainable production practices. Nano-particle pigment inks now offer enhanced color vibrancy and wash-fastness exceeding 50 cycles, addressing one of digital printing's longstanding limitations compared to traditional dye sublimation. Water-based formulations have reduced VOC emissions by up to 70% versus solvent-based alternatives, strongly supporting luxury fashion's growing environmental commitments.

Most disruptive is the integration of AI-powered design and production workflows within the digital printing ecosystem. Leading software providers have developed sophisticated platforms that automate color separation, fabric-specific color calibration, and even design generation based on trend analysis. These integrated systems reduce pre-production timelines from days to hours, enabling manufacturers to respond with unprecedented speed to emerging fashion trends—a critical advantage when speed-to-market often determines seasonal success.

Sustainability: From Industry Buzzword to Operational Imperative

The digital textile printing revolution is increasingly defined by environmental performance, not merely technological capabilities. As consumers become more conscious of fashion's environmental footprint, sustainable practices have evolved from market differentiators to basic requirements for industry participation.

Resource Efficiency remains digital printing's strongest sustainability advantage. The technology eliminates the water-intensive dye preparation and washing steps inherent in traditional methods, with industry studies consistently showing water consumption reductions of 70-90%. Energy usage is similarly reduced, with modern digital printing facilities reporting 30-40% smaller carbon footprints than conventional production setups.

Circular Economy Integration is rapidly emerging as an innovation frontier in digital scarf printing. Forward-thinking manufacturers have developed closed-loop systems that capture and reuse excess ink and pre-treatment solutions, nearly eliminating production waste. More progressive operations are designing scarves specifically for recyclability, utilizing digital printing to create products engineered for disassembly and repurposing at end-of-life.

Transparent supply chain practices are strengthening the sustainability narrative in digital scarf printing. Blockchain technology enables brands to verify material sourcing and production processes, ensuring sustainable claims encompass the entire product lifecycle rather than just the printing phase. Fashion brands increasingly require this level of transparency to meet consumer expectations and regulatory requirements in key markets worldwide.

Design Freedom and Customization Capabilities in Digital Printing

Digital printing has fundamentally redefined creative possibilities in scarf design, enabling customization and complexity that were previously either cost-prohibitive or technically unfeasible with traditional methods.

Unlimited Color Palettes offer immediate creative benefits for designers. Unlike screen printing, which requires separate screens for each color and inherently limits color counts, digital systems provide virtually unlimited color options without additional setup costs. This capability has revived intricate patterns and gradient effects in luxury scarf collections, with some designers now utilizing thousands of distinct colors in single designs—a previously unimaginable feat.

Variable Data Printing technology has opened new horizons for personalization and limited editions. This advanced capability allows manufacturers to incorporate unique elements such as monograms, serial numbers, or location-specific variations into individual scarves within a production run. Luxury brands are leveraging this technology to create highly exclusive offerings, sometimes producing just 10-20 personalized pieces that command significant premium pricing.

3D design visualization tools have streamlined the approval process between designers and production teams. Advanced software now enables designers and manufacturers to preview exactly how designs will appear on actual scarf fabrics, accounting for drape, texture, and light interaction before production commences. This capability reduces sampling costs, accelerates time-to-market, and ensures design intent translates accurately from digital concept to physical product.

Market Dynamics and Competitive Landscape in Digital Scarf Production

The digital scarf printing sector reflects broader transformation within the textile industry, characterized by consolidation among technology providers and increasing specialization among manufacturers, creating a complex and dynamic competitive landscape.

Market Segmentation has become increasingly distinct, with clearly defined service tiers emerging for different market segments. At the premium end, specialized manufacturers focus exclusively on high-end natural fibers—particularly silk and wool blends—offering minimum orders as low as 50 pieces with extensive customization options. These providers typically serve luxury fashion brands and high-end boutiques, emphasizing craftsmanship, exclusivity, and sustainability credentials.

Mid-tier manufacturers target the growing direct-to-consumer and corporate gift markets, offering moderate customization with faster turnaround times and more accessible price points. These operations often utilize polyester-rich blends and standardized processes to balance quality with cost efficiency.

At the volume end of the spectrum, large-scale producers employ high-speed digital printing lines to serve fast fashion retailers and promotional goods clients. These operations prioritize production efficiency and competitive pricing, usually requiring minimum orders in the thousands of units.

Competitive Differentiation now centers on technological specialization and service capabilities rather than mere production capacity. Leading providers distinguish themselves through specialized expertise in specific fabrics, unique finishing techniques, or integrated design services. Some have developed proprietary color management systems that ensure consistency across production runs and seasons—a critical capability for maintaining brand integrity in the luxury segment.

Strategic Considerations for Digital Printing Partnerships

Selecting the right digital scarf printing partner represents a strategic decision with far-reaching implications for product quality, brand reputation, and operational efficiency. Fashion manufacturers should approach this process with clearly defined criteria and realistic expectations.

Technical Capability Assessment should extend beyond basic equipment specifications to evaluate the entire production ecosystem. Key factors include color management systems, pre-treatment capabilities, and post-printing finishing processes—all of which significantly impact final product quality. Manufacturers should request samples printed on their specific fabrics to verify color accuracy, detail reproduction, and hand feel before entering into partnerships.

Production Flexibility has grown increasingly important in today's volatile market environment. Manufacturers should assess potential partners' ability to handle varying order sizes, meet compressed deadlines, and accommodate design modifications. The most valuable partners demonstrate clear communication throughout production and exhibit agility in addressing unexpected challenges.

Sustainability Credentials require thorough verification beyond marketing claims. Manufacturers should inquire about specific water and energy usage metrics, waste management practices, and certification status. Third-party certifications like GOTS (Global Organic Textile Standard) or OEKO-TEX provide valuable validation, but for critical partnerships, these should be complemented by site visits and process audits.

Cost Structure Analysis must account for total landed costs rather than focusing exclusively on per-unit printing prices. Shipping, duties, minimum order requirements, and sampling fees can significantly affect partnership economics. Manufacturers should also factor in potential costs from quality issues or delays, which often outweigh small differences in per-unit pricing.

Future Directions and Emerging Opportunities in Digital Scarf Printing

Looking ahead 3-5 years, several emerging trends will further transform digital scarf printing, creating both challenges and opportunities for fashion manufacturers willing to innovate.

Material Innovation will likely drive significant industry changes. New sustainable fiber blends and coated substrates will expand the possibilities of digital printing applications. Ongoing research into conductive inks and smart textiles suggests potential for interactive scarf designs incorporating simple sensors or display elements—applications that could particularly appeal to luxury accessories and tech-fashion crossover markets.

Process Automation will continue its advancement trajectory, with AI playing increasingly prominent roles in production planning, quality control, and design generation. Predictive maintenance systems already reduce downtime for printing equipment, while computer vision systems can identify and correct printing defects in real-time, significantly improving yield rates and quality consistency.

Circular Economy Integration will evolve beyond production efficiency to encompass product design and end-of-life considerations. Digital printing's on-demand capabilities align naturally with circular economy principles, enabling production models that minimize waste through精准 inventory management. Emerging business models may combine digital printing with product take-back programs, where used scarves are recycled and their fibers repurposed for new production.

As digital scarf printing technology continues to evolve, fashion manufacturers that strategically leverage these capabilities will gain significant advantages in design innovation, production efficiency, and sustainability performance. The most successful brands will view digital printing not merely as a production technique but as a catalyst for broader transformation in product development, supply chain management, and customer engagement.

In this dynamic landscape, selecting the right manufacturing partner becomes more than a tactical decision—it represents a strategic alliance with the potential to drive innovation, enhance brand value, and position fashion businesses for success in an increasingly competitive and environmentally conscious marketplace. For industry professionals navigating this evolving sector, staying informed about these trends and developments will be essential for maintaining competitive advantage in the rapidly changing world of digital scarf printing.