As a seasoned industry professional with decades of experience in fashion accessories, I understand that selecting the right custom scarf manufacturing partner directly impacts your brand reputation, product quality, and profitability. This comprehensive guide synthesizes real-world expertise and current industry practices to navigate the complexities of ordering custom scarves, with specific insights into collaborating with established manufacturers like FENNYSUN.

The Evolving Landscape of Custom Scarf Manufacturing in 2025

The custom scarf industry has undergone remarkable transformation driven by technological innovation and shifting consumer expectations. In 2025, three pivotal trends are reshaping the sector: cutting-edge digital printing technologies that deliver unprecedented design flexibility in scarves, an intensified focus on sustainable materials and ethical production practices, and the growing demand for accelerated turnaround times without compromising quality standards.

For wholesale buyers, these industry shifts present both opportunities and challenges. The ability to offer distinctive, eco-conscious products with rapid delivery timelines creates significant competitive advantage, yet requires strategic navigation of the manufacturing process. Industry analytics reveal that brands leveraging custom scarf manufacturing achieve average profit margins 15-20% higher than those utilizing mass-produced accessories—a compelling incentive for investment in personalized scarf production.

Pre-Production Planning: Building Your Foundation for Success

Before engaging with manufacturers, meticulous preparation is essential. Begin by clearly defining your objectives, target price point, and quality parameters. This foundational clarity will guide every subsequent decision, from material selection to design complexity.

Material Selection: Balancing Quality, Sustainability, and Cost

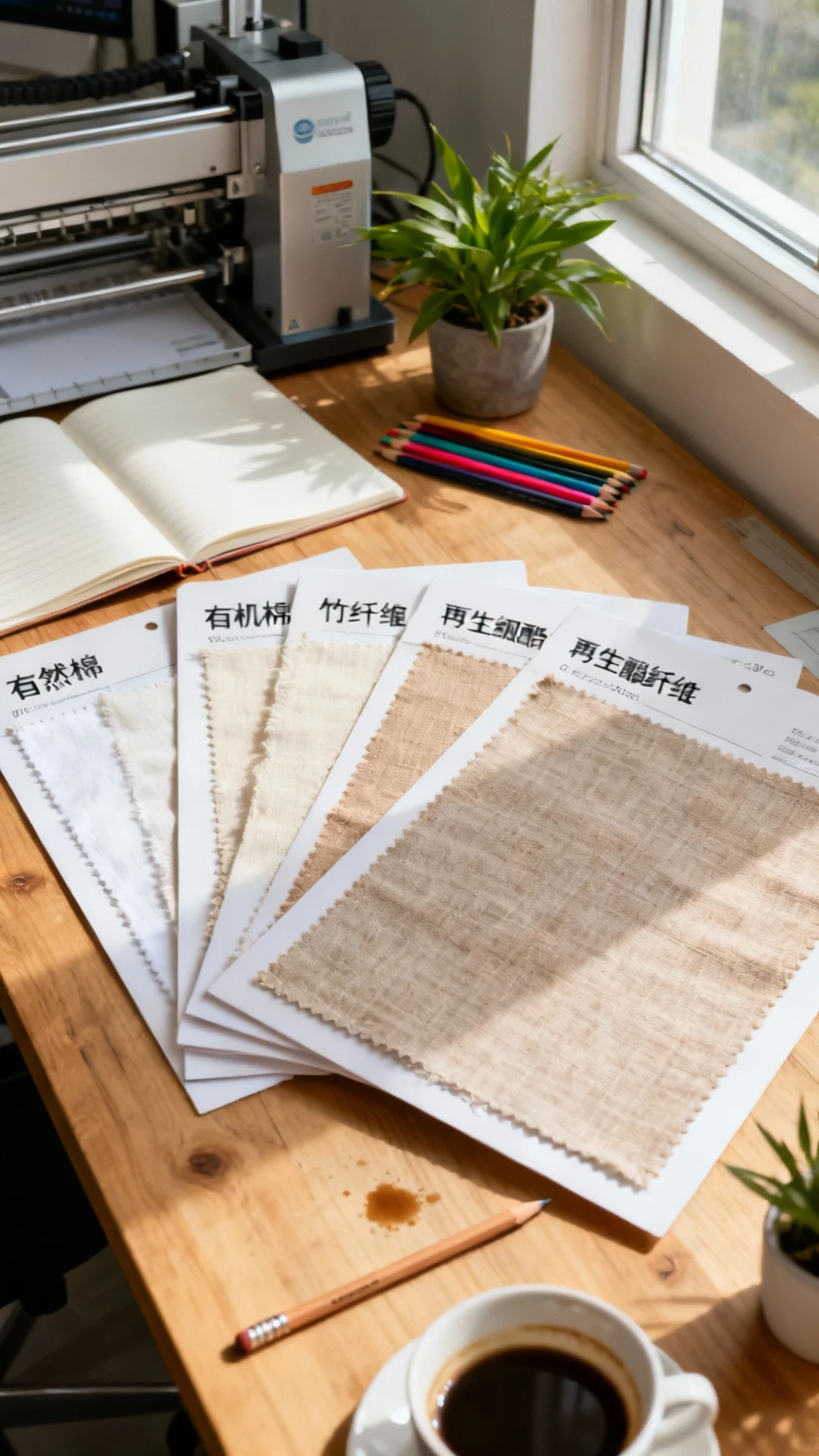

The fabric selection forms the cornerstone of any exceptional scarf. Today's discerning buyers increasingly prioritize sustainable options without sacrificing luxury or durability. Reputable custom scarf manufacturing partners typically offer an extensive range of materials:

- Silk: A timeless luxury choice offering natural sheen and exceptional drape, ideal for premium brand positioning

- Modal: Derived from sustainable beech tree fibers, providing superior breathability and silky softness

- Recycled polyester: An eco-conscious alternative that significantly reduces environmental impact while maintaining durability

- Organic cotton: Perfect for casual, lightweight designs with strong sustainability credentials

When evaluating materials, consider both aesthetic qualities and practical performance characteristics. Silk may require more careful handling but delivers unparalleled luxury appeal. Polyester blends offer enhanced durability and wrinkle resistance for everyday use. Leading manufacturers provide comprehensive material swatch books and detailed performance specifications to facilitate informed decision-making.

Design Development: Translating Concept to Technical Reality

Effective custom scarf design requires both creative vision and technical feasibility. When developing designs for personalized scarf production, consider these critical factors:

- Color complexity: Gradients and intricate color transitions may necessitate specific printing techniques

- Pattern scale: How your design translates across different scarf dimensions and sizes

- Repeat elements: Ensuring seamless pattern continuity, particularly for larger designs

- Logo placement: Strategic branding integration that enhances rather than distracts from the overall design

Many manufacturers offer in-house design services or can work with your existing design files. For optimal results, provide vector-based artwork with precise color specifications (Pantone numbers are industry standard). This technical precision minimizes costly revisions and ensures accurate color reproduction during manufacturing.

Selecting the Right Manufacturing Partner

Choosing a manufacturing partner represents one of the most consequential decisions in the custom scarf process. This selection directly impacts product quality, production timelines, minimum order quantities, and the overall collaboration experience.

Key Evaluation Criteria

When assessing potential bespoke scarf manufacturing partners, prioritize these essential factors:

- Technical capabilities: Do they possess the specific scarf customization technology required to execute your designs?

- Quality control protocols: What standards and inspection processes are implemented throughout production?

- Sustainability practices: What certifications and eco-friendly manufacturing processes do they employ?

- Communication responsiveness: How efficiently and clearly do they address inquiries and concerns?

- Production lead times: Can they consistently meet your timeline requirements?

- Minimum Order Quantities (MOQs): Do their requirements align with your volume needs and business model?

Industry benchmarks indicate that reasonable MOQs for digital printing typically start around 50 pieces per design. Traditional screen printing may require 100-200 pieces to achieve cost-effectiveness. Many manufacturers offer tiered pricing structures that reward larger orders with reduced per-unit costs, creating economies of scale for growing businesses.

Due Diligence: Verifying Claims and Capabilities

Before committing to a manufacturer, conduct thorough due diligence. Request samples of previous work and, when feasible, a small test run of your specific design. This hands-on evaluation provides invaluable insights into actual quality levels.

Additionally, inquire about certifications that validate their operational claims:

- OEKO-TEX®: Ensures fabrics are free from harmful substances and chemicals

- GOTS (Global Organic Textile Standard): Certification for organic fiber production and processing

- ISO 9001: Demonstrates adherence to international quality management system standards

Reputable manufacturers readily provide this documentation and may offer virtual or in-person factory tours to showcase their facilities, processes, and quality control measures.

The Custom Order Process: A Comprehensive Roadmap

Once you've selected a manufacturing partner and finalized designs, production typically unfolds in several distinct stages. While specific processes may vary slightly between providers, this framework outlines the standard journey:

Initial Consultation and Proposal Development

Begin by sharing comprehensive project details with your manufacturer, including design files, material preferences, desired quantities, and timeline constraints. A professional custom scarf manufacturing partner will provide a detailed proposal including:

- Transparent pricing breakdown: Per-unit costs, setup fees, and any additional charges

- Projected production timeline: Key milestones and delivery expectations

- Technical recommendations: Potential adjustments for optimal production results

- Payment terms: Typically requiring a deposit (often 30-50%) before production commences

Sample Development and Approval Process

Before full production begins, creating a pre-production sample is standard industry practice. This critical step allows you to:

- Verify color accuracy against specifications

- Assess fabric quality and print clarity

- Evaluate overall drape and aesthetic appearance

- Make necessary adjustments before mass production

Expect the sampling process to require 7-14 days, depending on design complexity. Most manufacturers include one or two revision rounds in initial pricing, with additional revisions potentially incurring extra costs and time.

Production Scheduling and Manufacturing Execution

Upon sample approval and deposit payment, your order enters production scheduling. This stage involves:

- Material sourcing: Procuring specified fabrics and production supplies

- Pre-production preparation: Setting up printing screens or digital files

- Manufacturing: The actual production process, varying significantly by printing method

- In-process quality control: Inspections at critical stages to ensure adherence to standards

The production phase typically requires 14-21 days for standard orders. However, advanced digital printing technologies have significantly reduced this timeframe for appropriate designs. Manufacturers utilizing state-of-the-art digital printing can often deliver custom orders in as little as 16 days—a 43% improvement over traditional manufacturing methods.

Finishing, Inspection, and Packaging

After printing, scarves undergo several essential finishing processes:

- Hemming: Creating clean, durable edges (hand-rolled hems denote premium quality)

- Steaming/pressing: Removing production wrinkles and setting the print

- Final inspection: Detailed quality assessment for any defects or inconsistencies

- Packaging: Folding and preparing for shipment, with options for custom branding elements

Reputable manufacturers maintain rigorous quality control standards, often inspecting each individual scarf to ensure it meets specified requirements before packaging.

Shipping and Logistics Coordination

The final step involves getting your custom scarves to their destination efficiently. Manufacturers typically offer multiple shipping options, allowing you to balance speed and cost considerations. For international shipments, ensure you understand import duties, taxes, and customs documentation requirements to avoid unexpected delays or expenses.

Managing Expectations and Troubleshooting Common Challenges

Even with meticulous planning, challenges can occasionally arise during manufacturing. Understanding potential issues and their solutions can save significant time, money, and frustration:

Establishing Effective Communication Protocols

Clear communication channels from the outset are critical for project success. Regular check-ins, especially during production, help identify and resolve issues early. Don't hesitate to request production updates or photos if concerns arise.

Anticipating Potential Delays

While manufacturers strive to meet established deadlines, unexpected delays can occur due to various factors:

- Material shortages or supply chain disruptions

- Equipment maintenance or technical issues

- Quality control concerns requiring rework

- Shipping/logistics complications

Building a 7-10 day buffer into your timeline is advisable. This contingency planning mitigates the impact of delays, especially when scarves are needed for specific events or seasonal launches.

Implementing Quality Control Protocols

Even with reputable manufacturers, occasional quality issues may surface. Establish clear expectations for defect rates and resolution processes before production begins. Most manufacturers have standard protocols for addressing issues, including:

- Replacement of defective items

- Partial refunds for substandard products

- Re-production of affected order portions

Maximizing Your Custom Scarf Investment

Custom scarves represent more than mere inventory—they're strategic brand assets. To maximize their impact:

Strategic Branding Integration

Thoughtful branding placement enhances perceived value and brand recognition. Consider subtle logo integration rather than overt branding that might diminish design appeal. The most effective custom scarves balance artistic design with strategic brand reinforcement.

Leveraging Storytelling and Marketing Opportunities

Harness the custom nature of your scarves in marketing initiatives. Share the design inspiration, manufacturing processes, and sustainability aspects with your audience. This authentic storytelling creates emotional connections and helps justify premium pricing.

Monitoring Performance Metrics

Track sales performance, customer feedback, and margin contribution to inform future customization projects. This data-driven approach helps refine your strategy, identifying what resonates with your audience and where improvements may be needed.

Conclusion: Transforming Vision into Exceptional Products

Ordering custom scarves represents a collaborative journey that, when approached strategically, yields exceptional results that differentiate your brand in a competitive marketplace. By selecting the right manufacturing partner, defining clear objectives, and understanding the production process, you can create scarves that delight customers while enhancing brand reputation and profitability.

Remember that successful custom scarf projects emerge from true partnerships between brand and manufacturer. When evaluating potential partners, look for those demonstrating not only technical expertise but also genuine interest in understanding your vision and helping you achieve your business goals.

With these insights and frameworks, you're well-equipped to navigate the custom scarf manufacturing landscape with confidence—transforming creative vision into tangible products that embody quality, sustainability, and distinctive style.