In the fiercely competitive landscape of luxury fashion accessories, textile innovation has emerged as the definitive cornerstone of brand differentiation and market leadership. With over three decades of immersion in textile manufacturing, I've witnessed firsthand how advanced materials have revolutionized the luxury scarf sector, creating unprecedented opportunities for boutiques, specialty retailers, and fashion houses alike. The year 2025 represents a pivotal inflection point where technical textiles, sustainable fibers, and performance fabrics converge to redefine luxury—not merely as an aesthetic concept, but as a sophisticated integration of craftsmanship, functionality, and environmental stewardship.

The Evolution of Luxury Scarf Materials: From Time-Honored Tradition to Technological Advancement

The luxury scarf industry has historically anchored itself in revered materials such as silk and cashmere, celebrated for their inherent beauty and tactile excellence. Today's discerning consumers, however, demand more than conventional opulence; they seek products that artfully merge innovation, sustainability, and versatility. This fundamental shift propels manufacturers to develop advanced scarf materials that preserve the essence of luxury while incorporating performance features previously absent in traditional textiles.

Reimagined silk spearheads this evolution. The quintessential luxury material now integrates technological enhancements including moisture-wicking blends and UV-protective weave structures, addressing practical concerns without compromising the fabric's intrinsic luxury. Similarly, cashmere innovations have yielded lighter, more resilient versions through nano-coating technologies that enhance abrasion resistance while preserving the fiber's legendary softness.

The most transformative development has been the emergence of performance fabrics specifically engineered for luxury scarves. These technical textiles incorporate functional properties such as temperature regulation, antimicrobial characteristics, and subtle stretch capabilities, catering to the modern consumer's active lifestyle while maintaining high-fashion appeal. Industry analyses project the global market for technical textiles in luxury fashion will grow at a compound annual rate of 5.03% through 2034, underscoring the increasing demand for these innovative materials.

Sustainable Fibers: Redefining Luxury Through Environmental Responsibility

Sustainability has transcended niche status to become a core value driver in the luxury scarf market. As environmental consciousness reshapes consumer decisions, sustainable fibers have evolved from ethical considerations to definitive markers of true luxury. The year 2025 introduces several groundbreaking developments in this domain:

Bio-based fibers lead this sustainable revolution. Innovations including mycelium leather scarves and seaweed-based textiles are gaining traction among eco-conscious luxury brands, offering environmental benefits alongside unique aesthetic qualities that distinguish them in the marketplace. Seaweed fibers, for instance, provide a subtle iridescence unattainable by synthetic alternatives—creating a compelling selling proposition that merges sustainability with visual allure.

Recycled luxury fibers have also achieved significant maturation. Advanced recycling technologies now transform post-consumer textile waste into high-quality fibers suitable for luxury applications. This closed-loop approach minimizes environmental impact while crafting a compelling narrative that resonates with consumers who prioritize transparency and circularity.

The adoption of sustainable materials presents distinct challenges, including sourcing consistency, scalability, and maintaining luxury quality standards. Industry leaders are addressing these obstacles through vertical integration and strategic partnerships with specialized material suppliers. Consequently, certification systems tailored specifically for luxury sustainable textiles are emerging, providing brands with verifiable credentials that foster consumer trust and loyalty.

Technical Textiles: Harmonizing Functionality with Luxury Aesthetics

Technical textiles represent the nexus of performance and luxury, offering capabilities once unimaginable in traditional scarf design. These advanced materials redefine the very concept of a scarf, transforming it from a purely aesthetic accessory into a functional, multi-purpose garment with enhanced utility.

Smart textile integration has introduced subtle technological elements that elevate user experience without compromising design integrity. Temperature-regulating scarves utilizing phase-change materials (PCMs) adapt dynamically to environmental conditions, providing warmth in cool environments and cooling effects during temperature increases. Moisture-wicking technical textiles ensure all-day comfort, rendering luxury scarves more practical for everyday wear than ever before.

Durability innovations have reconciled the longstanding tension between luxury and longevity. Nano-coating technologies applied to delicate fabrics such as silk and cashmere significantly enhance stain and abrasion resistance, extending product lifespan while preserving luxurious tactile qualities. This development not only enhances consumer value but aligns with sustainability principles by reducing replacement frequency and overall consumption.

The technical performance of these advanced materials undergoes rigorous testing against international standards. Organizations such as ASTM and ISO have established comprehensive protocols for evaluating breathability, water resistance, and colorfastness—ensuring technical textiles meet both performance claims and luxury quality expectations. For manufacturers and brands, adherence to these standards provides a competitive advantage through verified performance credentials that resonate with informed consumers.

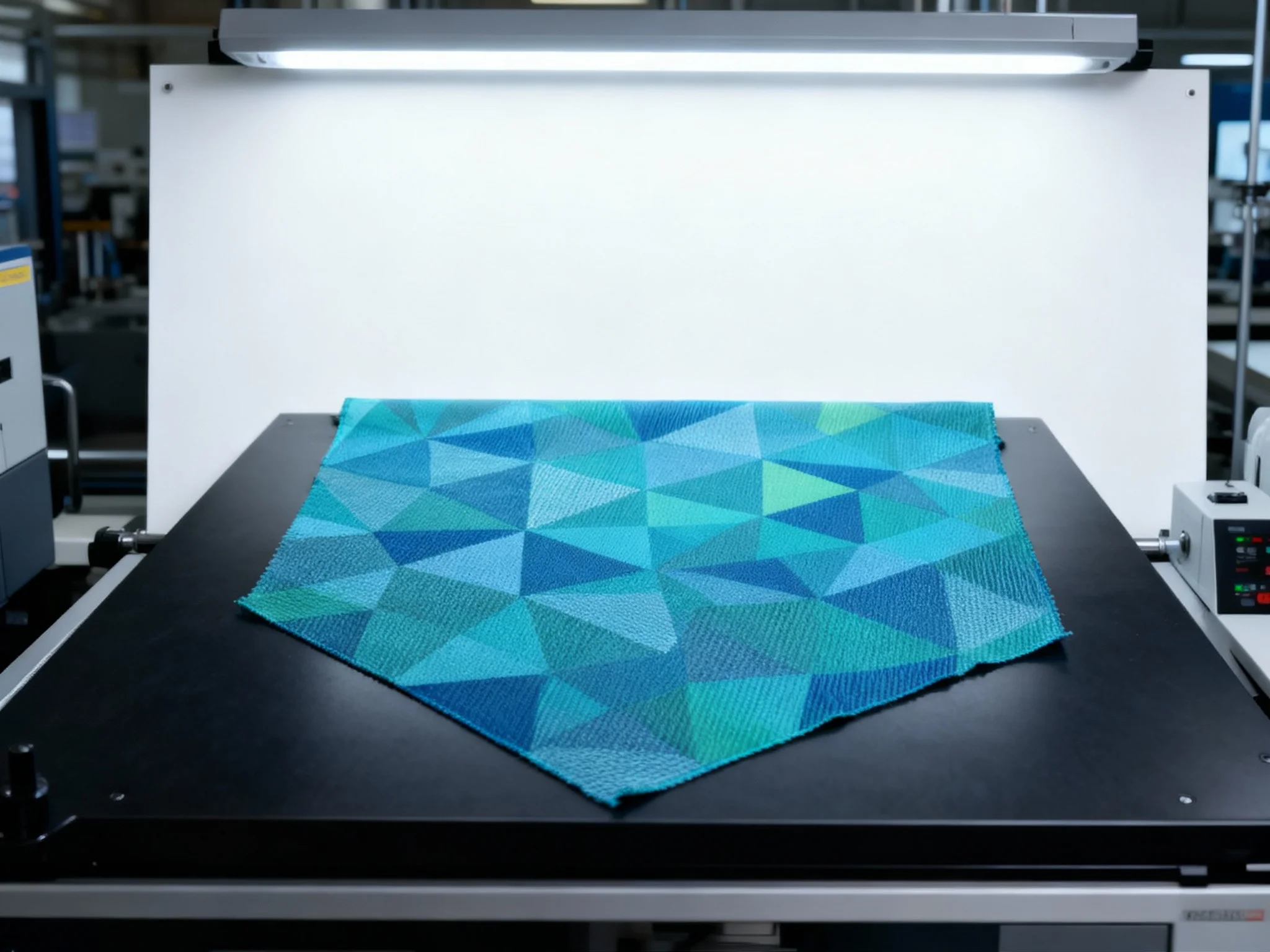

Digital Printing Technology: Precision, Efficiency, and Design Freedom

Digital printing technology has revolutionized scarf production, offering unprecedented design freedom and production efficiency while democratizing customization without sacrificing the quality standards essential for luxury positioning.

The most significant advantage of digital printing lies in its design flexibility. Unlike traditional screen printing, which requires substantial setup costs and performs optimally for large production runs, digital technology handles intricate, multi-color designs with minimal setup expenses. This capability unlocks new possibilities for limited-edition collections and personalized designs, fostering exclusivity while maintaining production efficiency—a critical balance in the luxury market.

From a sustainability perspective, digital printing offers substantial environmental benefits compared to conventional methods. The technology reduces water consumption by up to 95% and minimizes chemical usage, aligning with the luxury industry's growing commitment to eco-responsibility. On-demand production capabilities further reduce waste by enabling precise manufacturing quantities that align with market demand, preventing overproduction and excess inventory.

Quality control in digital printing has advanced considerably to meet luxury standards through sophisticated color management systems and high-resolution printing capabilities. Modern digital printers reproduce intricate designs with exceptional clarity, capturing the subtle nuances required for high-end scarf designs. Ink technology advancements have simultaneously improved wash fastness and color retention, addressing previous limitations of digital printing in luxury applications and ensuring long-lasting beauty.

Selecting the Right Manufacturing Partner: Strategic Considerations for Success

For boutiques, specialty stores, and fashion brands seeking to leverage textile innovations, selecting the right manufacturing partner represents a critical strategic decision that impacts product quality, sustainability credentials, and market competitiveness. Based on decades of industry experience, several key factors should guide this selection process:

Material expertise stands as an essential qualification. The ideal manufacturing partner should demonstrate profound knowledge of both traditional luxury materials and emerging technical textiles, ensuring selected materials align with the brand's aesthetic vision and performance requirements while offering insights into new innovation possibilities.

Production technology integration capabilities are equally important. Manufacturers who have invested in advanced production technologies—not merely digital printing but also automated cutting systems and sophisticated quality control technologies—offer greater consistency, efficiency, and customization capabilities that translate directly into product quality and competitive advantage.

Sustainability practices should be evaluated beyond marketing claims. A truly sustainable manufacturing partner demonstrates transparency throughout the supply chain, from raw material sourcing to production processes and waste management. Certifications from recognized organizations provide independent verification, offering assurance to both brands and their consumers regarding environmental claims.

A collaborative approach distinguishes exceptional manufacturing partners from merely competent ones. The most successful partnerships involve manufacturers who contribute creative insights and technical solutions, functioning as true collaborators in product development rather than passive producers. This collaborative mindset often yields innovative solutions that might not emerge from purely transactional relationships.

Future Trends: The Next Frontier in Luxury Scarf Materials

Looking beyond 2025, several emerging trends will further transform the luxury scarf industry, continuing to blur boundaries between traditional luxury and technical innovation while creating new opportunities for forward-thinking brands.

Biofabrication represents the next frontier in sustainable luxury. This cutting-edge technology grows textile fibers from cell cultures, eliminating the need for traditional agricultural or animal sources. While still in early stages of commercialization, biofabricated materials offer unprecedented customization of fiber properties with minimal environmental impact, potentially revolutionizing material sourcing for luxury applications.

Enhanced sensory experiences through material science will create new dimensions of luxury. Textile engineering innovations enable fabrics that respond to touch, temperature, or sound—creating interactive experiences that engage multiple senses simultaneously. These developments could redefine luxury as an immersive experience rather than merely a visual and tactile one, opening new avenues for brand storytelling and consumer engagement.

Circular economy integration will deepen as recycling technologies advance. Chemical recycling processes capable of breaking down blended textiles into their constituent fibers will enable true closed-loop systems for luxury scarf production. This advancement not only reduces environmental impact but creates opportunities for innovative business models centered around take-back programs and material regeneration, strengthening brand-consumer relationships through shared environmental values.

These converging trends point toward a future where luxury scarf materials are defined not by tradition alone but by the harmonious integration of heritage craftsmanship, technical innovation, and environmental responsibility. For brands embracing these developments, the potential for differentiation and market leadership is substantial, particularly among increasingly discerning consumers.

Conclusion: Embracing Innovation While Honoring Luxury Heritage

Textile innovation has catalyzed a profound transformation in luxury scarf materials, driving significant industry evolution. Performance fabrics, sustainable fibers, and advanced manufacturing technologies are not replacing traditional luxury values—they are expanding the definition of luxury to meet modern consumer expectations that demand both substance and sustainability alongside style.

For boutiques, specialty stores, and fashion brands, this evolution presents both challenges and opportunities. Success hinges on selecting manufacturing partners with expertise spanning both traditional craftsmanship and emerging technologies, enabling brands to leverage the latest textile innovations while maintaining the quality, exclusivity, and storytelling that define true luxury in the marketplace.

Looking ahead, the most successful luxury scarf brands will embrace innovation without abandoning the craftsmanship and quality principles that have defined the industry for generations. By integrating technical textiles, sustainable practices, and digital technologies, these brands will create products that resonate with contemporary consumer values while maintaining the timeless appeal that makes luxury scarves enduring wardrobe staples with transcendent value.

The textile innovation journey in luxury scarves continues to unfold, with new developments emerging regularly. Brands that establish flexible, forward-thinking partnerships with manufacturing experts will adapt most effectively to these changes and maintain leadership positions in an increasingly competitive market. Ultimately, the fusion of innovation and tradition will define the next generation of luxury scarf design and production, creating products that honor heritage while embracing the future.