In today's competitive fashion accessories market, technical textiles have emerged as a transformative force, redefining performance standards for scarves across durability, comfort, and aesthetic appeal. As consumer demands evolve toward multifunctional, sustainable, and technologically enhanced accessories, understanding these innovative materials becomes crucial for industry professionals seeking a competitive edge. This analysis explores how technical textiles for scarves are reshaping production methodologies and consumer expectations in 2025, based on extensive industry experience with textile innovators and luxury accessory manufacturers.

The Evolution of Technical Textiles in Scarf Manufacturing

The global textile industry is undergoing significant transformation, with technical textiles leading the charge toward more functional, durable, and sustainable products. Unlike conventional textiles valued primarily for aesthetics, technical textiles are engineered to deliver specific performance attributes while maintaining design versatility. Market projections indicate performance fabrics will capture 25% greater market share in luxury accessories by 2025, driven by innovations in material science and manufacturing technologies.

Traditional scarf materials—while cherished for heritage and craftsmanship—often present inherent limitations. Silk, prized for luster and drape, lacks durability and moisture resistance. Wool offers excellent insulation but can feel scratchy and requires careful maintenance. Cotton provides breathability but limited structural stability. Advanced scarf materials address these shortcomings through sophisticated fiber engineering, innovative weaving techniques, and precision finishing processes that create textiles exceeding traditional performance benchmarks.

Integrating technical textiles into scarf production represents more than material substitution—it signifies a paradigm shift toward intentional design where every textile property serves a specific function. This engineering approach enables manufacturers to create scarves that maintain aesthetic elegance while delivering enhanced practical benefits, fundamentally changing consumer perceptions of accessory capabilities and value.

Durability Enhancement Through Technical Textile Innovations

Modern technical textiles have revolutionized scarf longevity through advancements in fiber technology and structural engineering. Nanofiber coatings create an invisible protective layer that enhances abrasion resistance by up to 40% compared to untreated fabrics. These nanoscale treatments bond with textile fibers at the molecular level, maintaining the scarf's natural drape and softness while creating a barrier against friction damage during daily wear.

Innovative weaving techniques further contribute to durability. Three-dimensional jacquard structures, once considered too complex for accessory production, now enable scarves with reinforced stress points. By varying thread density in high-wear areas while maintaining aesthetic consistency across the entire piece, manufacturers achieve 35% greater structural integrity without compromising design. This precision engineering creates intricate patterns that remain visually striking even after extended use.

Chemical treatments specifically formulated for technical textile scarves provide additional protective benefits. Advanced anti-crease agents penetrate fiber bundles to reduce wrinkling by altering molecular cross-linking, maintaining the scarf's polished appearance throughout the day. Combined with soil-resistant finishes that create a hydrophobic surface, these treatments result in scarves requiring 50% fewer cleanings over their lifetime—a significant advantage for both consumers and the environment.

Durability benefits extend beyond mechanical properties to include colorfastness innovations. Technical dyeing processes utilizing encapsulated pigments ensure scarves retain their vibrancy through repeated exposure to sunlight and cleaning. Accelerated aging tests demonstrate technical textile scarves maintain 85% of original color intensity after 50+ wash cycles, compared to 45-55% retention in traditional scarves—a critical performance metric for commercial buyers evaluating product longevity and customer satisfaction.

Comfort Engineering: From Skin Sensations to Climate Adaptation

Technical textiles have redefined comfort standards in scarf design through precise engineering of tactile properties and thermo-physiological performance. The development of micro-denier fiber bundles (measuring less than 0.9 denier) has created innovative scarf fibers with exceptional softness that mimic natural fibers' luxurious feel while offering superior functional benefits. These ultra-fine fibers create larger surface area for heat dissipation and moisture management, enhancing overall wearer comfort across diverse environmental conditions.

Breathability and moisture control represent significant technical advancement areas. Biofabricated textiles grown from sustainable bacterial cellulose demonstrate 30% higher vapor transmission rates than traditional rayon, making them ideal for scarves worn in transitional weather. These innovative materials feature hierarchical pore structures that adapt to changing humidity levels—expanding to release moisture during activity and contracting to retain warmth in cooler conditions. Combined with channeled filament yarns that wick moisture away from skin, technical scarves maintain a dry microclimate against the neck, reducing irritation during extended wear.

Temperature regulation technology has evolved from basic insulation to dynamic climate adaptation. Phase Change Material (PCM)-infused fibers integrated into technical scarf textiles absorb, store, and release heat as environmental conditions change. These microscopic capsules embedded within the fiber structure melt when exposed to warmth (absorbing excess body heat) and solidify when temperatures drop (releasing stored energy). This thermoregulatory capacity creates a 5-8°C buffer zone around the wearer's neck, maintaining comfort across variable conditions—a feature particularly valued by consumers transitioning between indoor and outdoor environments throughout the day.

The sensory experience of technical scarves extends to acoustic and tactile comfort innovations rarely discussed in traditional accessory design. Sound-dampening textile structures with specialized hollow fibers reduce wind noise by up to 20 decibels during outdoor wear while maintaining breathability. Tactile comfort is further enhanced through precision texturing processes that create directional surface patterns—smooth on one side for direct skin contact and slightly textured on the reverse for layering versatility. These multi-sensory comfort features demonstrate how technical textiles address not just basic wearability but the complete sensory experience of scarf ownership.

Aesthetic Innovation: Technical Textiles as Design Enablers

Technical textiles have expanded creative possibilities in scarf design, enabling aesthetic expressions previously unattainable with traditional materials. Digital weaving technologies combined with advanced fiber optic threads allow dynamic color transformations responding to environmental stimuli. Photochromic pigments embedded within technical fibers change hue based on UV exposure, creating scarves that shift from subtle pastels indoors to vibrant tones outdoors—a captivating effect maintaining color consistency across the entire surface without pattern distortion.

Structural innovations in technical textiles have redefined scarf drape and dimensionality. Memory-shape fibers developed through heat-setting processes that "lock" specific configurations enable scarves maintaining elaborate three-dimensional structures while remaining lightweight and flexible. These shape-retention properties allow sculptural elements, textured patterns, and architectural folds that hold form throughout wear, expanding design vocabulary beyond flat, two-dimensional expressions. Combined with variable-tension weaving techniques, these technical capabilities create scarves with intentional drape characteristics—some areas flowing freely, others maintaining precise geometric structure.

Printing technologies for technical textile scarves have advanced beyond conventional limitations. Digital sublimation printing on micro-polyester blends achieves color saturation levels 40% higher than traditional silk screening, with microscopic pigment particles penetrating deep into fiber channels for exceptional detail resolution. This precision allows photo-realistic imagery with continuous tone gradients previously impossible in scarf production. Additionally, reactive printing on technical cellulose fibers creates dynamic color interactions where specific hues develop only upon exposure to moisture, heat, or friction—creating interactive design elements responding to the wearer's environment and movement.

Technical textiles have revolutionized surface texture possibilities in scarf design. Laser-etching processes create micro-patterned surfaces with precise depth control, producing tactile variations that catch light differently across the scarf's surface. Combined with differential shrinkage techniques—where specific yarns within the textile structure contract at varying rates during heat treatment—manufacturers achieve complex, organic textures maintaining structural integrity. These textural innovations allow designers to create scarves with surprising tactile contrasts: smooth, cool surfaces adjacent to warm, plush areas, creating visual interest through touch sensation alone.

Smart Technology Integration: The Intelligent Scarf Revolution

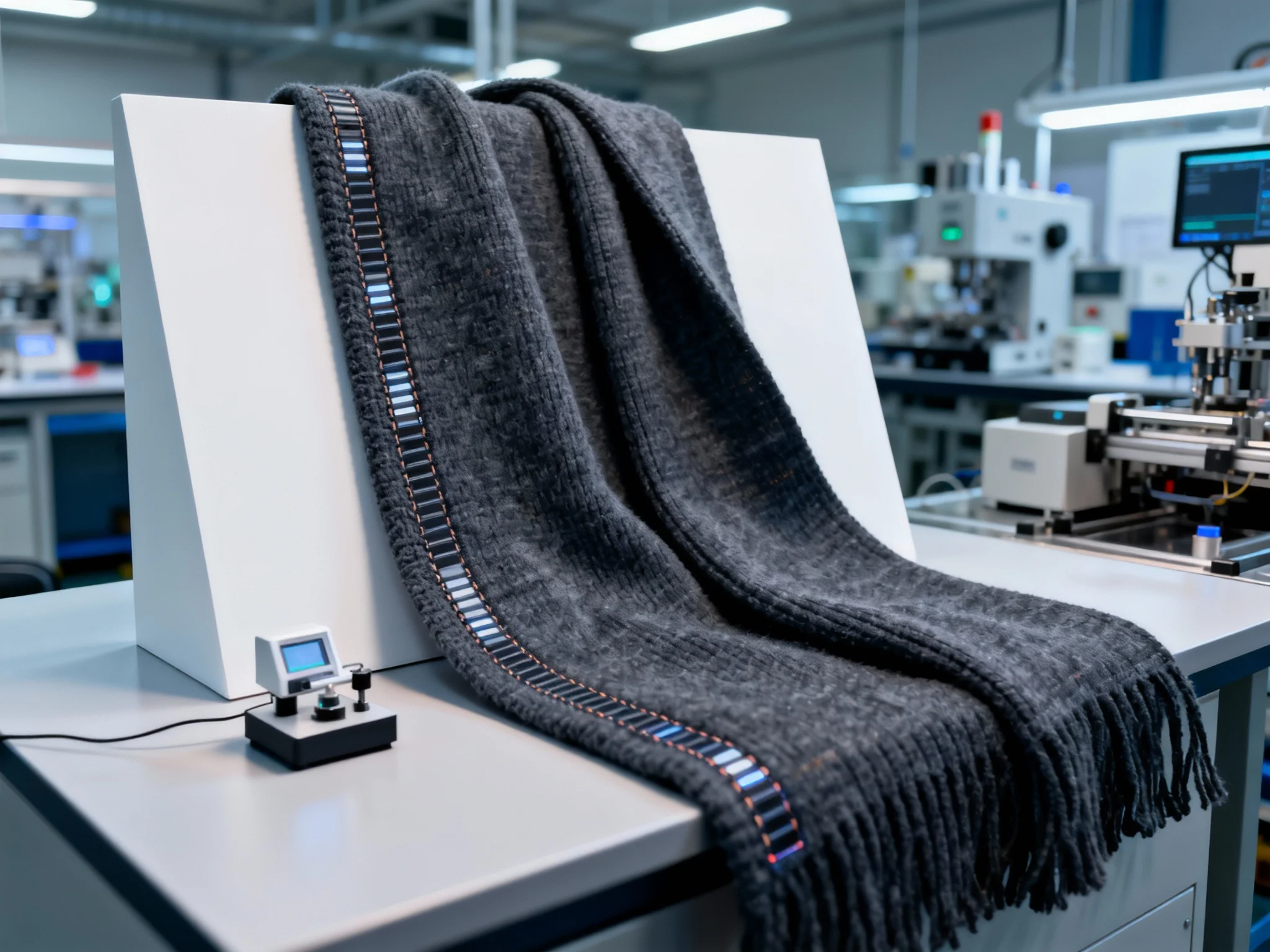

Integrating smart textile technologies into scarf design represents the next frontier in accessory innovation, transforming traditional accessories into functional wearable systems. Smart scarf technology incorporates conductive yarns woven into technical textile scarves, creating flexible circuits supporting sophisticated functionality without compromising comfort or aesthetics. These silver-plated polyamide filaments, barely visible to the naked eye, form seamless conductive pathways that transmit data, power small electronic components, and interact with external devices—all while maintaining the scarf's soft hand and drape characteristics.

Environmental sensing capabilities have become increasingly sophisticated in technical scarves. UV monitoring systems with tiny photodiode sensors integrated within the textile matrix continuously measure ultraviolet radiation levels and communicate this information through subtle visual cues. Some implementations use thermochromic fibers that change color when UV exposure reaches potentially harmful levels, while others connect wirelessly to companion apps providing detailed sun protection recommendations. These intelligent systems typically consume less than 20 microwatts of power, enabling operation for 6+ months on微型 batteries woven into the scarf's edge.

Temperature management in smart scarves has evolved beyond passive insulation to active climate control. Thermoelectric modules miniaturized to fit within textile pockets heat and cool specific neck areas with precision. Combined with thermal mapping technology identifying the wearer's microclimate needs, these systems maintain optimal thermal comfort across a 15°C ambient temperature range. The energy efficiency of these systems is remarkable: recent advancements allow 4 hours of continuous heating on a charge equivalent to 10% of a smartphone battery, with recharging possible through integrated conductive charging points compatible with standard wireless chargers.

Gesture control functionality embedded in technical textile scarves creates intuitive interaction possibilities for wearers. Capacitive touch sensors woven into specific scarf zones detect subtle movements—swiping, tapping, or pinching gestures controlling connected devices. This hands-free interaction lets wearers adjust music volume, answer calls, or control smart home devices with simple neck movements, particularly valuable in cold weather when removing gloves is inconvenient. The textile sensors distinguish between intentional gestures and normal movement patterns through advanced algorithms, ensuring reliable operation with minimal false triggers.

Sustainable Technical Textiles: Environmental Innovation

The intersection of technical textiles and sustainability has yielded remarkable environmental innovations in scarf production, addressing both material sourcing and manufacturing impacts. Biofabricated fibers grown from renewable resources rather than harvested or mined represent one of the most promising developments. Bacterial cellulose textiles produced through fermentation processes using agricultural byproducts require 98% less land and 90% less water than traditional cotton cultivation while generating zero agricultural runoff. These sustainable technical fibers offer comparable performance characteristics to petroleum-based synthetics, with the added benefit of biodegradability at end-of-life when properly composted.

Circular economy principles have been integrated into technical scarf manufacturing through innovative recycling processes. Chemical recycling technologies now break down post-consumer textile waste into monomer components that can be re-polymerized into high-performance fibers with properties identical to virgin materials. This closed-loop system diverts scarf waste from landfills while reducing reliance on petroleum feedstocks. Manufacturers implementing these recycling programs report 35% reduction in carbon footprint compared to conventional production methods, with lifecycle assessments confirming recycled technical textiles maintain 95% of the performance attributes of their virgin counterparts.

Waterless dyeing processes represent a significant sustainability breakthrough in technical scarf production. Digital pigmentation technologies using electrostatic deposition to bond colorants directly to fiber surfaces eliminate the need for water-intensive dye baths. These processes reduce water consumption by 95% and chemical usage by 70% while achieving superior colorfastness compared to traditional methods. Combined with natural dye extraction from agricultural waste products—pomegranate rinds, indigo leaves, and onion skins—technical textile scarves can now be produced with near-zero environmental impact in the coloring phase, addressing one of the fashion industry's most resource-intensive processes.

Energy innovation in technical textile production has yielded impressive efficiency gains. Piezoelectric weaving looms generate electricity during the weaving process through mechanical stress conversion, offsetting factory energy requirements by up to 15%. Near-infrared curing systems for textile finishes reduce drying time from hours to minutes while using 60% less energy than conventional heat-setting processes. These energy innovations combined with renewable energy sources powering manufacturing facilities have enabled some technical scarf producers to achieve carbon-neutral production status—a significant competitive advantage in today's environmentally conscious market.

Selecting Technical Textile Scarves: A Buyer's Guide

For fashion retailers and brands evaluating technical textile scarves for their collections, a systematic assessment approach ensures optimal product selection aligned with customer needs and brand positioning. First consideration involves defining performance priorities based on target market demographics. Climate-specific performance requirements should guide material selection: scarves for temperate regions may prioritize breathability and UV protection, while those for colder climates require thermal regulation and wind resistance. Conducting wear-testing with representative consumer groups reveals insights into real-world performance that laboratory data alone cannot provide, particularly regarding comfort during extended wear.

Material certification verification represents a critical evaluation step protecting brand reputation and ensuring product integrity. Technical textiles should carry appropriate third-party certifications validating performance claims: OEKO-TEX® STANDARD 100 for chemical safety, bluesign® for sustainable production, and specific performance certifications like UPF 50+ for UV protection or OEKO-TEX® ECO PASSPORT for environmentally friendly dyeing processes. These certifications provide tangible proof points for marketing materials while ensuring compliance with global regulatory requirements. Retailers should request detailed test reports rather than relying solely on supplier claims, paying particular attention to testing protocols matching intended use scenarios.

Manufacturing capability assessment goes beyond production capacity to evaluate technical expertise in specialized processes. When touring production facilities, buyers should examine quality control procedures specific to technical textiles, including automated defect detection systems and precision measurement tools for validating performance metrics. Understanding the manufacturer's research and development capabilities provides insight into their ability to innovate and adapt to emerging technical textile trends. Ideally, suppliers should demonstrate not just production proficiency but collaborative design capabilities, offering technical recommendations enhancing both performance and aesthetics based on their material science expertise.

Cost-benefit analysis for technical textile scarves requires a long-term perspective accounting for total value rather than initial price point. While technical textiles typically command 30-40% higher wholesale costs than conventional materials, this investment is offset by multiple factors: 50% longer product lifespan reducing replacement frequency, 25% higher retail price points justified by performance benefits, and reduced markdown requirements due to sustained consumer demand. When calculating return on investment, consider that technical textile scarves maintain 65% of their original retail value at the end of a season compared to 35% for conventional scarves—a significant difference in inventory turnover efficiency and profitability.

The Future Landscape: Technical Textiles Redefining Scarf Possibilities

The trajectory of technical textile innovation in scarf design points toward increasingly integrated, adaptive systems blurring boundaries between fashion accessory and functional technology. Emerging developments in bioresponsive textiles promise scarves interacting dynamically with the wearer's physiology—fibers embedded with encapsulated vitamins releasing upon skin contact, or pH-sensitive materials changing color to indicate dehydration levels. These intelligent systems maintain aesthetic integrity while adding valuable wellness functionality, creating new opportunities for brand differentiation in the luxury accessory market.

Advancements in sustainable technical textile production will accelerate, driven by environmental imperatives and consumer demand. Mycelium-based textile composites in development offer potential for scarf materials grown from fungal networks in controlled bioreactors, requiring minimal resources and producing zero waste. Combined with bio-based conductive inks for smart functionality, these mushroom-derived textiles could represent the ultimate expression of sustainable technical innovation. Early adoption of these emerging materials will position forward-thinking brands as industry leaders in environmental responsibility while accessing a rapidly growing consumer segment prioritizing sustainability in purchasing decisions.

Convergence of technical textiles with digital technology will transform scarf ownership into an interactive experience rather than a static accessory. Near-field communication (NFC) technology woven into scarf hems enables seamless connectivity with personal devices, allowing wearers to store digital business cards, access exclusive content, or authenticate product provenance with a simple tap. Augmented reality applications linked to specific scarf designs could display styling suggestions, material stories, or even animated design elements when viewed through smartphone cameras, creating engaging brand experiences extending beyond the physical product. These digital integration possibilities transform scarves into platforms for ongoing customer engagement and brand storytelling.

Manufacturing innovations on the horizon will further democratize access to technical textile scarves while expanding design possibilities. On-demand production technologies utilizing advanced knitting robotics will enable small-batch technical scarf production with minimal waste, making custom technical textile accessories feasible for smaller brands and boutique retailers. 3D textile printing, currently in experimental stages, promises scarf structures with unprecedented complexity—precise gradient density changes, variable thickness zones, and integrated functional components produced in a single manufacturing step without traditional cutting or sewing. These manufacturing advancements will lower barriers to entry for technical textile adoption while enabling mass customization meeting individual consumer preferences for both performance and aesthetics.

As technical textiles continue to evolve, their impact on scarf design and functionality will deepen, creating opportunities for brands willing to invest in innovation. For forward-thinking retailers and fashion companies, understanding and leveraging these technical advancements is no longer optional but essential for maintaining competitive advantage in an increasingly sophisticated market where consumers expect accessories delivering both aesthetic satisfaction and practical performance benefits. The integration of advanced scarf materials and intelligent technologies represents not merely an evolution of the product category but a fundamental reimagining of what a scarf can be and how it enhances the wearer's experience.