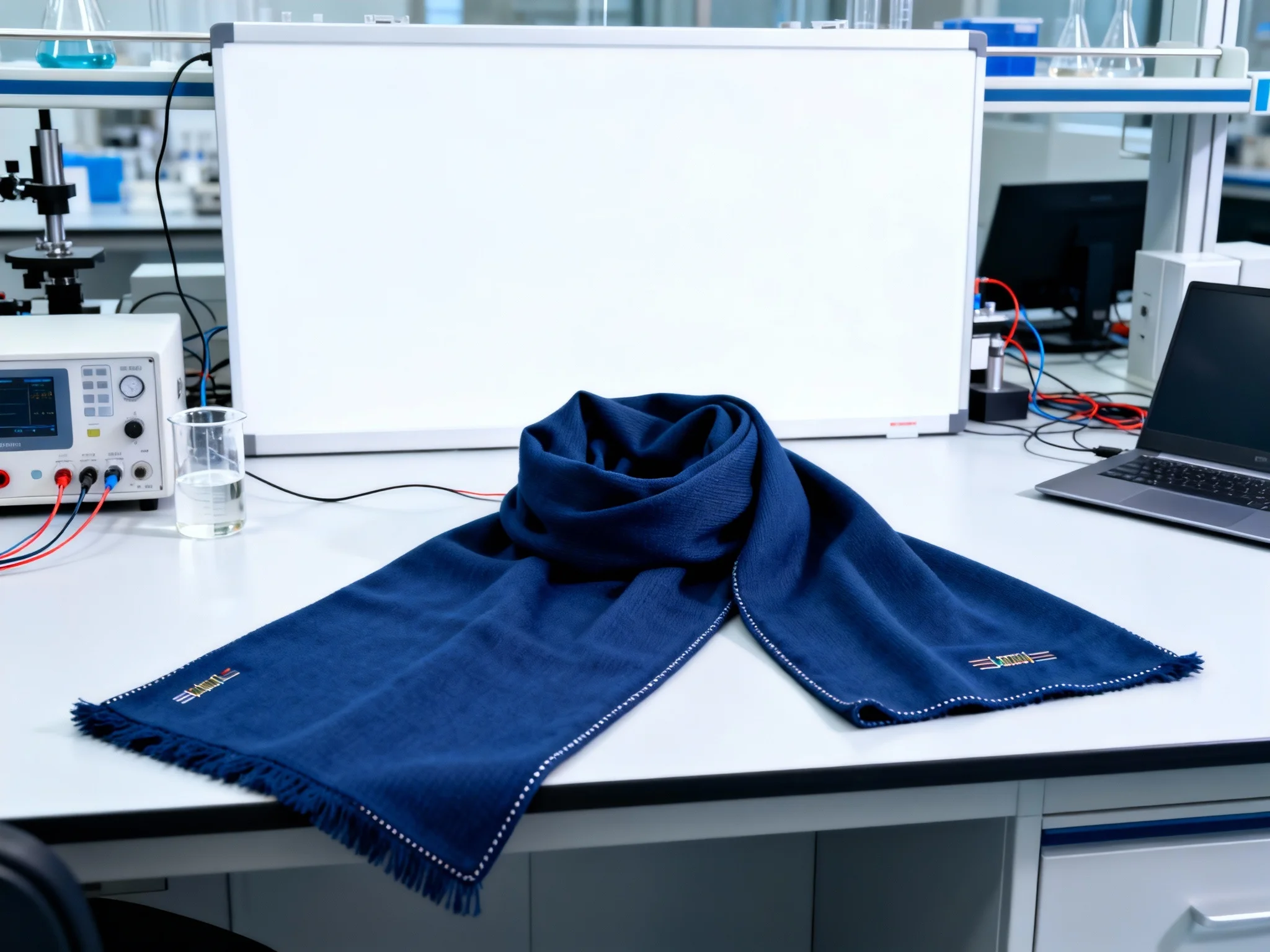

In today's rapidly evolving fashion accessories landscape, sustainable advanced materials are driving a paradigm shift in technical scarf manufacturing—one that harmonizes innovation with environmental responsibility. With extensive experience in textile technology and sustainable fashion, I've witnessed firsthand how material science breakthroughs are addressing both performance needs and ecological concerns. The global scarf market, valued at approximately $23.38 billion in 2025, is undergoing a remarkable transformation driven by consumer demand for products that deliver superior functionality without compromising planetary health.

The Evolution of Technical Scarf Materials

The technical textiles sector remains at the forefront of material science innovation, with advancements that hold particular relevance for accessory manufacturing. Valued at USD 205.4 billion in 2024, the technical textiles market is projected to grow at a CAGR of over 4.9% from 2025 to 2034—a testament to the increasing adoption of advanced materials across industries, including fashion accessories.

Within scarf manufacturing specifically, this evolution progresses along three distinct pathways:

Performance Enhancement Through Material Science

Modern technical scarves now incorporate advanced fibers that deliver multifaceted benefits previously limited to high-performance sportswear. These include sophisticated temperature regulation, moisture management, UV protection, and antimicrobial properties—features that enable seamless transition between environments, from urban commutes to outdoor adventures.

Sustainable Sourcing and Production

The industry is undergoing a significant shift toward materials that minimize environmental impact throughout the supply chain. Innovations include recycled polyester derived from post-consumer plastic bottles, regenerated cellulose fibers from agricultural waste, and cutting-edge bio-based materials that reduce reliance on petroleum-based products. Notably, these sustainable alternatives increasingly match—if not exceed—the performance characteristics of traditional materials.

Intelligent Textiles and Smart Integration

While still emerging in scarf applications, smart textile technologies are making notable inroads. These innovations range from conductive fibers enabling subtle heating elements to photochromic materials that respond dynamically to light conditions. Early explorations into energy-harvesting fabrics also suggest potential for scarves that could one day power small electronic devices.

Key Sustainable Advanced Materials in 2025

The material landscape for technical scarves in 2025 presents innovative solutions that simultaneously address performance requirements and sustainability goals. Based on current industry trends and material science advancements, several key materials have emerged as market leaders:

Recycled Technical Fibers

Recycled polyester continues to gain traction, with processing advancements yielding fibers with improved softness and drape—qualities critical for fashion scarves. These advanced scarf materials maintain the durability and wrinkle resistance of virgin polyester while diverting plastic waste from landfills and oceans.

Bio-Based Performance Materials

Innovative bio-based fibers derived from renewable resources offer compelling alternatives to traditional materials. These include polylactic acid (PLA) fibers from corn starch, mycelium-based textiles, and proteins extracted from agricultural by-products. These materials not only reduce carbon footprints but often biodegrade naturally at the end of their lifecycle.

Advanced Natural Fiber Blends

Traditional natural fibers such as wool and silk are being elevated through advanced processing techniques and strategic blending with technical fibers. The result is scarves that retain the luxurious qualities of natural materials while incorporating performance attributes like stretch, shape retention, and enhanced durability.

Nanotechnology-Enhanced Fabrics

Nanotechnology applications in textiles have yielded scarves with specialized properties—including water resistance, stain repellency, and odor control—all without compromising breathability or comfort. These treatments increasingly utilize eco-friendly chemistries that minimize environmental impact while delivering exceptional performance.

Sustainable Manufacturing Processes

Innovation in technical scarf materials extends beyond raw fibers to encompass the entire manufacturing ecosystem. As environmental regulations tighten and consumer awareness grows, manufacturers are embracing more sustainable production methodologies:

Low-Impact Dyeing and Finishing

Traditional dyeing processes consume vast quantities of water and often involve hazardous chemicals. The industry is transitioning toward sustainable alternatives, including digital printing technologies that reduce water usage by up to 95% compared to conventional methods. Natural dye extracts from plants and minerals are also being revitalized with modern extraction techniques, offering vibrant color palettes with minimal environmental impact.

Energy-Efficient Production

Manufacturing facilities are increasingly integrating renewable energy sources such as solar and wind power. Energy-efficient machinery and process optimization further reduce carbon footprints, with leading manufacturers reporting energy savings of 30% or more compared to conventional production setups.

Circular Economy Approaches

Forward-thinking manufacturers are designing production processes with circularity as a core principle, creating systems where waste materials are minimized and repurposed. This includes textile recycling programs, take-back initiatives for end-of-life products, and modular design approaches that facilitate repair and reuse.

Certification Standards and Compliance

In an industry where sustainability claims can lack substantiation, certification standards provide critical verification of environmental credentials. For technical scarf manufacturers targeting the boutique and fashion brand market, several key certifications have become essential:

OEKO-TEX® Certification

The updated OEKO-TEX® 2025 standards represent a significant advancement in textile safety and sustainability, introducing stricter limits on substances of concern, enhanced transparency requirements for supply chains, and new provisions for organic cotton certification. For scarf manufacturers, compliance demonstrates a tangible commitment to both consumer safety and environmental responsibility.

Global Organic Textile Standard (GOTS)

GOTS certification remains the benchmark for organic textiles, ensuring materials originate from organic agriculture and are processed using environmentally and socially responsible methods. For scarves marketed as organic, GOTS certification provides comprehensive assurance across the entire supply chain, from fiber production to finished product.

Bluesign® System

The Bluesign® system takes a holistic approach to textile production, focusing on resource efficiency, chemical management, and worker safety. This certification is particularly relevant for technical textiles for scarves as it addresses the full lifecycle of the product and encourages continuous improvement in environmental performance.

Application and Performance Testing

Technical scarves incorporating advanced materials require rigorous testing to validate performance claims and durability expectations. As part of development protocols, manufacturers implement comprehensive testing regimens:

Functional Performance Testing

This evaluates specific technical properties such as moisture vapor transmission, thermal resistance, UV protection factor, and breathability. These tests ensure performance claims are substantiated and that scarves will perform reliably in real-world conditions.

Durability and Wear Testing

Technical scarves must maintain their functional properties and aesthetic appeal through repeated use and laundering. Accelerated wear testing—including abrasion resistance and colorfastness evaluations—helps ensure product longevity and customer satisfaction.

Sustainability Metrics Verification

Beyond performance, manufacturers increasingly measure and verify the environmental impact of their technical scarves throughout their lifecycle. This includes carbon footprint calculations, water usage assessments, and waste generation analyses—data that supports continuous improvement and transparent communication with customers.

Industry Trends and Future Directions

The technical scarf market is evolving rapidly, driven by material innovations, sustainability imperatives, and changing consumer expectations. Looking ahead, several key trends are shaping the development of innovative scarf fibers for scarf manufacturing:

Multifunctional Design

Consumers increasingly seek accessories that serve multiple purposes, driving demand for scarves with modular components, convertible designs, and integrated technologies that enhance versatility. The goal is products that deliver exceptional value by adapting to various wear scenarios and user needs.

Personalization and Customization

Advancements in digital printing and manufacturing technologies enable greater personalization of technical scarves, ranging from custom colorways and patterns to tailored performance attributes based on specific climate conditions or personal preferences.

Transparency and Traceability

As sustainability concerns grow, consumers demand greater transparency regarding the origins and environmental impact of products they purchase. Blockchain technology and digital product passports are emerging as solutions, providing unprecedented visibility into supply chains, material sourcing, and manufacturing processes.

Smart Scarf Technology Integration

The integration of smart scarf technology represents one of the most exciting frontiers in technical scarf development. This includes conductive fibers for subtle heating elements, photochromic materials that respond to light conditions, and early explorations of energy-harvesting fabrics that might one day power small electronic devices.

Biofabrication and Lab-Grown Materials

While still in early stages, biofabrication techniques show tremendous promise for creating entirely new textile materials with precise performance characteristics and minimal environmental impact. Lab-grown materials could potentially revolutionize technical scarf manufacturing by offering unprecedented control over material properties while eliminating resource-intensive agricultural practices.

Practical Considerations for Boutique Buyers

For boutique owners and fashion brands evaluating technical scarf suppliers, several key considerations should guide selection:

Material Authenticity and Performance Claims

Verify that performance claims are supported by credible testing and certification. Request detailed specifications and test reports for any performance fabrics or technical materials, and consider third-party verification to ensure transparency.

Sustainability Credentials

Evaluate suppliers based on comprehensive sustainability metrics rather than marketing claims alone. Look for evidence of continuous improvement in environmental performance and commitment to social responsibility throughout the supply chain.

Minimum Order Quantities and Production Flexibility

Many technical scarf manufacturers require significant minimum order quantities, which can present challenges for smaller boutiques. Seek suppliers that offer flexible production options or sample programs to mitigate risk when introducing new technical materials.

Design Collaboration Opportunities

The most successful technical scarf partnerships often involve collaborative design processes that leverage the supplier's material expertise while incorporating the brand's aesthetic vision. Look for manufacturers willing to engage in product development and customization.

Lead Times and Supply Chain Reliability

Technical textiles for scarves may involve more complex supply chains and longer lead times. Ensure suppliers have robust contingency plans for potential disruptions and can provide consistent quality across production runs.

Conclusion: The Future of Technical Scarf Materials

Material science innovation and sustainability imperatives are driving profound changes in technical scarf manufacturing. Looking ahead, advanced materials development will continue to focus on both performance enhancement and environmental responsibility, creating products that deliver exceptional functionality while minimizing ecological impact.

For fashion brands and boutiques, this evolution presents both challenges and opportunities. Success requires staying informed about material innovations, verifying sustainability claims through credible certifications, and partnering with manufacturers at the forefront of technical textile development.

Ultimately, the most successful technical scarves will seamlessly integrate advanced functionality with sustainable materials, creating products that meet the complex needs and values of modern consumers. By embracing these innovations, the industry can move toward a more sustainable future while delivering exceptional value and performance to customers.

As material science continues to advance, we can expect even more remarkable developments in technical scarf materials—innovations that will further blur boundaries between fashion and technology while setting new standards for environmental responsibility in the textile industry. The future of scarf manufacturing lies in materials that don't just perform better, but do better for our planet.