In today's rapidly evolving fashion manufacturing landscape, scarf producers face the intricate challenge of balancing traditional craftsmanship with modern efficiency, customization demands with production scalability, and artisanal heritage with technological innovation. As boutique owners and luxury fashion brands increasingly seek premium quality and consistent supply chains, implementing robotic production systems has transitioned from a competitive advantage to a business necessity. This comprehensive guide outlines critical considerations for scarf manufacturers embarking on their automation journey in 2025, exploring textile automation technologies, implementation strategies, and future trends shaping the smart textile factory of tomorrow.

The Strategic Imperative for Automation in Scarf Manufacturing

The global textile automation market is projected to grow at a compelling CAGR of 8.2% through 2025, reaching $664 million in value. This remarkable growth stems from the convergence of artificial intelligence, advanced robotics, and sustainability initiatives transforming manufacturing paradigms. For scarf manufacturers specifically, this technological revolution directly addresses three pressing industry challenges:

Quality Consistency remains the cornerstone of success in the scarf market, where subtle variations in pattern alignment, fabric tension, or color matching can significantly impact perceived value. Traditional manual production typically results in a defect rate of 8-12%, whereas automated systems utilizing computer vision and precision robotics reduce defects to under 2%. This dramatic quality improvement directly translates to reduced waste, enhanced brand reputation, and greater satisfaction among discerning boutique clients who demand perfection in premium accessories.

Production Flexibility has become essential for meeting the fast-changing demands of contemporary fashion cycles. Modern robotic systems can switch between designs in minutes rather than hours, enabling manufacturers to offer the small-batch, customized production that specialty stores increasingly require. A recent case study from a European apparel manufacturer demonstrated that flexible automation reduced changeover time by 75%, allowing them to service 40% more design variations annually without expanding production capacity—a game-changing advantage in the dynamic accessories market.

Sustainability Targets now influence purchasing decisions at both retail and consumer levels. Automated systems optimize material usage through precision cutting algorithms, reducing fabric waste by up to 15%. Energy-efficient robotic cells also consume 10-15% less power than traditional production lines. This dual benefit of material and energy efficiency aligns perfectly with sustainability commitments that forward-thinking brands emphasize through their manufacturing practices, creating a compelling environmental narrative alongside operational improvements.

Technology Selection Framework for Scarf Manufacturers

Successful implementation of robotic production systems requires strategic technology selection aligned with specific manufacturing goals and product characteristics. Based on 2025 textile automation trends and practical applications, scarf manufacturers should consider three primary technology categories that form the foundation of the smart textile factory:

Computer-Aided Cutting Systems represent the most mature automation investment for scarf production, offering rapid ROI through material savings and increased throughput. Laser-guided cutting machines equipped with AI nesting algorithms optimize pattern placement to minimize waste while handling delicate fabrics like silk and cashmere with exceptional precision. A 2025 case study from a luxury accessories manufacturer demonstrated that such a system reduced material costs by 12% and increased cutting capacity by 35% within the first year of implementation. When evaluating cutting systems, manufacturers should prioritize those with adaptive material handling capabilities for the diverse fabrics used in high-end scarf production.

Collaborative Robotics (Cobots) are transforming sewing and finishing operations by working alongside human operators to enhance productivity while preserving artisanal quality. Unlike traditional industrial robots, cobots feature advanced sensor technology enabling safe interaction with human workers, making them ideal for the small to medium production facilities common in the scarf industry. Leading systems incorporate force-sensing technology that automatically adjusts stitching pressure based on fabric type, ensuring consistent quality across materials from lightweight silk to heavy wool blends. The International Federation of Robotics reports that textile manufacturers implementing cobot sewing cells have seen productivity increases of 20-30% while maintaining or improving product quality metrics—a testament to the power of human-robot collaboration.

AI-Powered Quality Inspection has emerged as a critical technology for maintaining premium standards in the scarf market. Advanced vision systems using deep learning algorithms detect subtle defects, pattern misalignments, and color variations that may escape even the most trained human eye. These systems can process up to 100 scarves per minute with 99.7% accuracy, significantly reducing the number of defective products reaching customers. In 2025, the latest inspection systems incorporate spectral analysis capabilities that verify color consistency across production runs, ensuring that the vibrant hues and subtle gradients defining premium scarf collections remain consistent from the first to the thousandth piece produced.

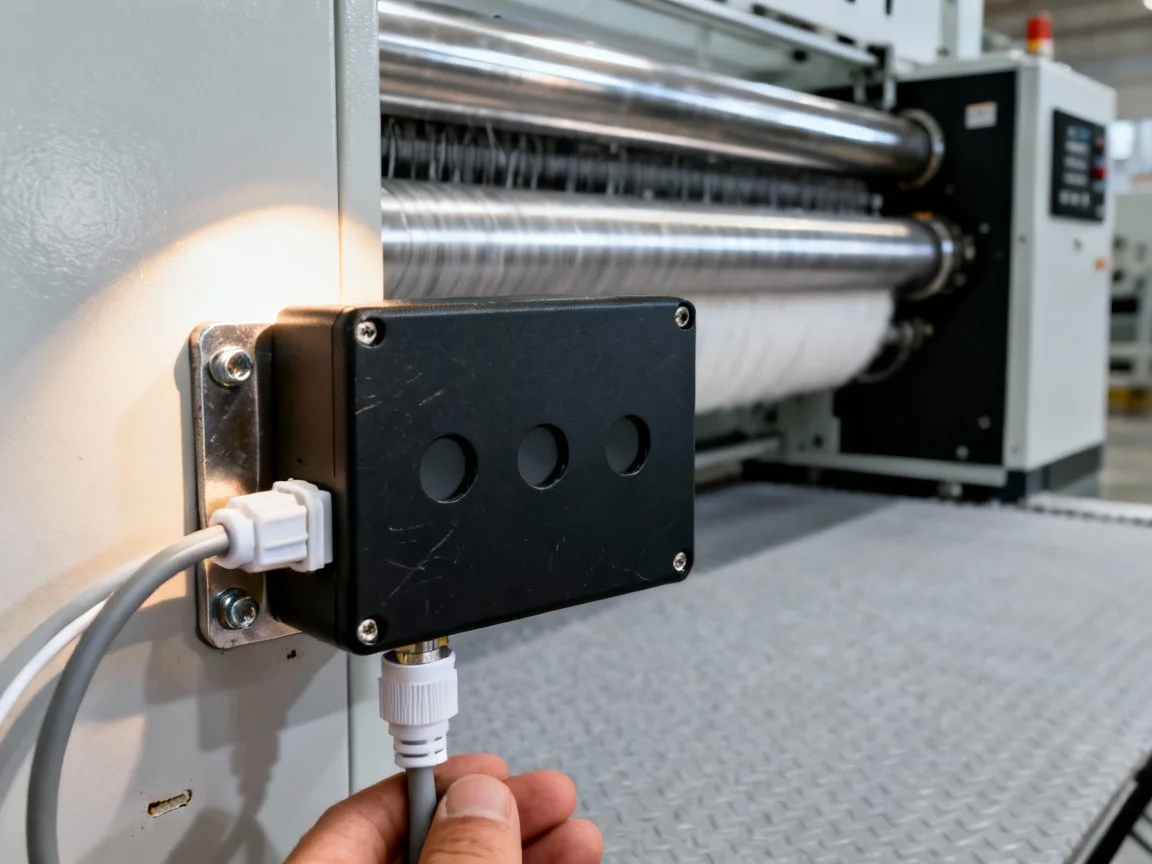

IoT Textile Monitoring systems represent the connective tissue of the smart textile factory, providing real-time visibility into production processes. These sensor networks track everything from fabric tension during weaving to environmental conditions that might affect material quality, enabling proactive adjustments before quality issues arise. IoT textile monitoring creates a data-rich environment where manufacturers can identify inefficiencies, predict maintenance needs, and optimize production flows—turning traditional manufacturing into a data-driven operation.

Implementation Roadmap and Change Management

Successfully integrating robotic production systems requires more than technological investment; it demands a comprehensive implementation strategy addressing operational, technical, and human factors. Based on industry best practices and change management research, manufacturers should follow a phased approach that balances innovation with operational continuity:

Phase 1: Assessment and Planning (2-3 months) begins with a thorough analysis of current production processes to identify automation opportunities and establish clear performance metrics. This assessment includes fabric handling requirements, production volume patterns, quality control pain points, and workforce skills analysis. A critical component involves developing a detailed business case accounting for total cost of ownership—including installation, training, maintenance, and integration with existing systems—while projecting ROI based on realistic productivity gains and material savings. Manufacturers should engage key stakeholders from production, design, and management teams throughout this process to ensure alignment with broader business objectives. For scarf producers working with sustainable materials, this phase should also evaluate how automation enhances environmental performance through reduced waste and energy consumption.

Phase 2: Pilot Implementation (3-4 months) allows manufacturers to test selected technologies in controlled production environments before full-scale deployment. This phase typically focuses on a single production process, such as cutting or quality inspection, to validate performance claims and identify integration challenges. Well-designed pilot programs include defined success criteria, regular performance reviews, and comprehensive data collection to inform the broader implementation strategy. During this phase, operators and technicians receive initial training on new systems, developing the skills needed to maximize productivity and troubleshoot common issues. For example, a pilot program for a cobot sewing cell might begin with a limited production run of a standard scarf design, gradually introducing more complex patterns and fabrics as operators gain proficiency.

Phase 3: Full-Scale Deployment and Optimization (6-12 months) expands successful pilot projects to broader production operations while continuously refining processes based on real-world performance data. This phase requires careful planning to minimize disruption to ongoing production, often using a phased rollout across product lines or production shifts. Comprehensive training programs ensure all relevant employees develop the technical and operational skills to work effectively with automated systems. Concurrently, manufacturers should establish preventive maintenance schedules to maximize equipment uptime and longevity. The optimization process leverages the data collection capabilities of smart manufacturing systems to identify efficiency opportunities, fine-tune production parameters, and further integrate automation across the value chain.

Throughout all implementation phases, effective change management is critical to overcoming resistance and building workforce buy-in. Communication strategies should emphasize how automation enhances rather than replaces human craftsmanship, highlighting opportunities for employees to develop new skills and focus on higher-value tasks. Manufacturers that involve workers in the implementation process and recognize their contributions to automation success consistently achieve better-than-projected productivity gains and ROI targets.

ROI Analysis and Performance Measurement

Financial justification for robotic production systems in scarf manufacturing requires a comprehensive analysis of costs, benefits, and long-term strategic value. Based on 2025 industry data and textile automation case studies, manufacturers can expect multi-faceted returns on investment:

Quantifiable Financial Returns typically materialize within 6-18 months, depending on the technology implemented and production volume. Labor cost savings represent the most immediate benefit, with automated cutting systems reducing operator requirements by 1-2 personnel per shift while increasing throughput. A mid-sized scarf manufacturer producing 50,000 units annually might save $80,000-$I20,000 annually in direct labor costs alone. Material savings, though often overlooked, can be equally significant—AI-optimized cutting systems reduce fabric waste by 10-15%, translating to savings of $I50,000-$I00,000 annually for manufacturers working with premium materials. Quality improvements further enhance financial performance by reducing rework costs and minimizing rejected products, which can represent 5-8% of production volume in manual operations.

Operational Performance Metrics provide valuable insights into how automation impacts production processes beyond direct financial returns. Key performance indicators should include:

- Overall Equipment Effectiveness (OEE): Measuring availability, performance, and quality to assess equipment utilization

- Cycle Time Reduction: Tracking production time per unit before and after automation implementation

- Changeover Efficiency: Monitoring time required to switch between product designs or materials

- Defect Rate: Quantifying quality improvements through automated inspection systems

- Energy Consumption: Evaluating sustainability benefits of modern, energy-efficient automation

A 2025 study by the Textile Automation Association found that manufacturers implementing comprehensive performance measurement systems achieved 22% higher ROI from automation investments compared to those focusing solely on financial metrics. These operational insights enable continuous improvement by identifying bottlenecks, optimizing maintenance schedules, and refining production processes.

Strategic Value Creation represents the most far-reaching benefit of robotic production systems, positioning scarf manufacturers for long-term success in competitive markets. Automation enables greater production flexibility, allowing manufacturers to quickly respond to changing fashion trends and customer demands—a critical capability in fast-paced accessories markets. The data collection and analysis capabilities of smart manufacturing systems provide valuable insights into production patterns, quality issues, and material performance, informing strategic decisions about product development and supply chain management. For brands emphasizing sustainability, automated systems offer enhanced tracking of material usage and waste generation, providing the transparency needed to validate environmental claims to increasingly conscious consumers and retail partners.

Addressing Implementation Challenges

While the benefits of robotic production systems are compelling, scarf manufacturers face several implementation challenges requiring proactive management. Based on industry surveys and implementation case studies, three critical challenges stand out:

Technical Integration Complexity poses significant hurdles, particularly for manufacturers with legacy production systems. Integrating new robotic systems with existing software platforms, material handling equipment, and production workflows often reveals compatibility issues that can delay implementation and increase costs. To mitigate this challenge, manufacturers should adopt open architecture approaches, selecting modular automation systems using standard communication protocols. Engaging systems integrators with specific textile application experience early in the planning process reduces integration risks, as these specialists understand the unique requirements of fabric handling and scarf production. A 2025 analysis of textile automation projects found that manufacturers conducting thorough compatibility testing during pilot phases reduced integration-related delays by 40% compared to those rushing into full-scale deployment.

Workforce Transition Management represents perhaps the most significant human resource challenge, as automation fundamentally changes job roles and required skills. Displacement of traditional manufacturing tasks can create resistance among long-tenured employees, potentially undermining implementation efforts. Forward-thinking manufacturers address this through comprehensive workforce development programs preparing employees for new roles in automated production environments. This includes technical training on robot operation and maintenance, plus upskilling opportunities in areas like production data analysis and system programming. Communication is equally important—manufacturers should clearly articulate how automation enhances rather than eliminates jobs, emphasizing opportunities for employees to transition to more skilled, higher-value roles. Successful programs often include "robot champion" initiatives that train early adopters to serve as mentors for colleagues during transition processes.

Sustainability Alignment has emerged as a critical implementation consideration, particularly for premium brands focused on environmental responsibility. While automation offers significant sustainability benefits through reduced waste and energy consumption, the production and disposal of robotic systems present their own environmental challenges. Manufacturers should evaluate automation suppliers based on environmental commitments, including equipment energy efficiency, use of recycled materials in construction, and take-back programs for end-of-life disposal. The total carbon footprint of automation projects should account for not just operational energy use but also embodied carbon in manufacturing equipment itself. For scarf producers using sustainable materials, integrating automation with existing environmental management systems ensures productivity gains don't come at the expense of broader sustainability goals.

Future Trends and Continuous Improvement

The field of textile automation continues evolving rapidly, with several emerging trends poised to further transform scarf manufacturing in the coming years. Forward-thinking manufacturers should monitor these developments to maintain a competitive advantage:

AI-Driven Design-to-Production Integration breaks down traditional silos between creative design and manufacturing execution. Advanced software platforms now enable direct translation of digital designs into production-ready patterns, automatically generating cutting paths, sewing instructions, and quality inspection parameters needed for robotic systems. This integration reduces lead times from design concept to production launch by up to 50%, a critical advantage in fast-paced fashion accessories markets. For scarf manufacturers, this technology enables more frequent design refreshes and rapid response to emerging fashion trends, while maintaining the precision and consistency that automated production provides. As these integrated systems mature, we'll see closer collaboration between design and manufacturing teams, with real-time production data informing design decisions to optimize both aesthetics and manufacturability.

Digital Twin Technology is beginning to transform production planning and optimization for scarf manufacturers. Creating virtual replicas of physical production systems allows manufacturers to simulate different production scenarios, test process improvements, and predict maintenance needs without disrupting actual production. This technology proves particularly valuable for small-batch production runs common in scarf manufacturing, enabling producers to optimize setup parameters for each design before physical production begins. A 2025 case study from a European textile manufacturer demonstrated that digital twin technology reduced setup times for new designs by 30% and improved production yield by 15% through virtual optimization. As implementation costs continue decreasing, even small to medium-sized manufacturers will find this technology accessible and beneficial.

Advanced Material Handling Systems address the unique challenges of scarf production, where delicate fabrics require specialized handling to maintain quality. Emerging technologies include vacuum-based gripping systems that conform to fabric contours, ultrasonic cutting tools that minimize fraying, and electrostatic handling systems that eliminate marking on delicate materials like silk and cashmere. These innovations expand the range of fabrics that can be processed automatically, enabling manufacturers to maintain the premium material quality that defines luxury scarf collections. When combined with AI vision systems that detect subtle fabric imperfections, these advanced handling technologies ensure only the highest quality materials proceed through production, reducing waste and enhancing finished product quality.

The future of robotic production systems in scarf manufacturing will be defined by increasing integration of these technologies into cohesive, data-driven production ecosystems. As leading brands continue emphasizing innovation and sustainability, automation will play increasingly critical roles in delivering on brand promises while maintaining the artisanal quality that distinguishes premium scarves in the marketplace.

Conclusion: A Strategic Approach to Textile Automation

Implementation of robotic production systems represents a transformative opportunity for scarf manufacturers seeking to balance tradition with innovation, quality with efficiency, and craftsmanship with scalability. As the textile industry continues its rapid technological evolution, manufacturers must approach automation as a strategic journey rather than a one-time investment, continuously evaluating new technologies and refining processes to maintain competitive advantage.

For premium brands and manufacturing partners, the path forward involves aligning automation investments with core brand values—whether emphasizing sustainability, artisanal quality, or innovative design. The most successful implementations will enhance rather than replace the human expertise that creates distinctive scarf designs and ensures exceptional quality. By focusing on collaborative robotics, intelligent quality control, and data-driven process optimization, manufacturers create production systems that honor craft traditions while embracing technological innovation.

Looking to the future, integration of AI-driven design tools, digital twin technology, and advanced material handling systems will further blur boundaries between design and production, enabling unprecedented customization and responsiveness to market trends. For forward-thinking manufacturers, these technologies offer the opportunity to transform scarf production from a labor-intensive process into a sophisticated blend of artisanal expertise and technological precision.

Ultimately, the measure of successful automation won't be how many human tasks can be replaced, but how effectively technology enhances human creativity, quality craftsmanship, and sustainable production practices. In this way, robotic production systems represent not just a means to greater efficiency, but a pathway to elevating the art of scarf making for the digital age—creating beautiful, sustainable accessories that meet the evolving expectations of discerning consumers and retail partners alike. As textile automation continues to advance, the smart textile factory of tomorrow will serve as a model of how traditional craftsmanship and cutting-edge technology can come together to redefine manufacturing excellence.