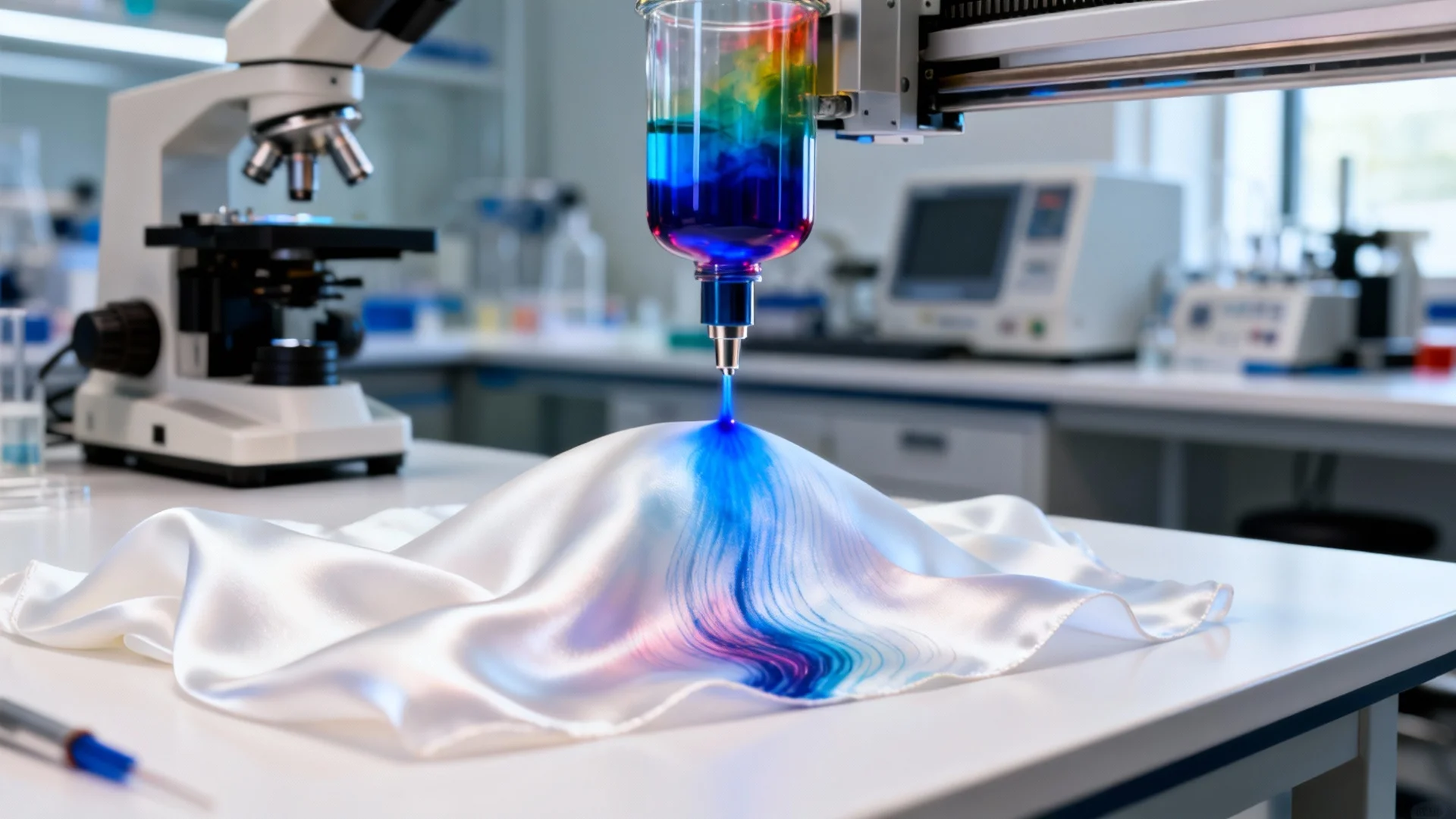

In today's competitive fashion accessories market, scarf printing has evolved from traditional craftsmanship to a sophisticated fusion of art and technology. As an industry professional with extensive experience in digital textile production, I've witnessed firsthand how nano-ink technology revolutionizes color vibrancy and design possibilities in scarf manufacturing. This comprehensive guide explores the technical foundations, process optimizations, and practical applications that enable fashion brands to achieve exceptional color results through advanced digital textile printing techniques.

The Technical Advantages of Nano-Ink in Scarf Printing

Nano-ink technology represents a significant advancement in digital textile printing, addressing longstanding challenges in color saturation, durability, and fabric compatibility. Unlike conventional pigment inks, nano-inks utilize particles measuring 100 nanometers or smaller—approximately 1/1000th the diameter of a human hair. These infinitesimal particles create unique optical and physical properties that transform scarf printing outcomes.

The most significant advantage lies in superior color expression. Industry testing confirms that nano-inks achieve up to 30% higher color gamut coverage than traditional textile inks. They excel at reproducing vibrant reds, deep blues, and subtle pastels that often challenge conventional methods—a critical factor for luxury scarf designs where color accuracy can determine a collection's success.

Nano-inks also offer exceptional surface adhesion capabilities. The nanoscale particles penetrate fabric fibers more thoroughly while forming stronger molecular bonds with various textile substrates—from delicate silk to textured wool blends. This results in prints with enhanced rub resistance and wash fastness, key quality indicators for high-end fashion accessories. Recent market data demonstrates that nano-ink printed scarves maintain up to 85% of their original color intensity after 20 wash cycles, significantly outperforming traditional digital prints.

Essential Equipment and Material Considerations for Optimal Results

Achieving superior color results with nano-ink technology requires careful attention to equipment compatibility and material selection. High-speed digital printing machines calibrated specifically for nano-ink applications have become industry standards, with leading manufacturers offering models capable of speeds up to 1,200 square meters per hour while maintaining precision droplet placement.

When evaluating printing equipment for nano-ink applications, focus on three critical factors: print head technology, color management systems, and drying capabilities. Piezoelectric print heads with variable droplet technology (6-150 picoliters) provide the control necessary to render both delicate color gradients and bold solid areas with consistent density. Advanced color management systems featuring spectrophotometric feedback loops ensure color accuracy across production runs and between different printing sessions.

Nano-inks demonstrate excellent performance across a wide range of scarf fabrics, though pretreatment requirements vary by material type. For natural fibers like silk and wool, acid-based pretreatments help open fiber structures to maximize ink penetration. Synthetic blends often require heat-activated primers to enhance color development. Industry best practices recommend conducting compatibility testing with specific fabric-ink combinations before initiating full production runs, as optimal results depend on the precise interaction between nano-particles and textile fibers.

Process Optimization Strategies for Color Excellence

The journey from digital design to finished printed scarf involves several critical stages where process optimization directly impacts color vibrancy. Implementing a systematic approach to each phase ensures consistent, high-quality results that meet the exacting standards of fashion brands and boutique retailers.

Design Preparation serves as the foundation for color success. Working with high-resolution digital files (minimum 300 DPI) containing ICC profiles specific to your nano-ink and target fabric ensures accurate color reproduction from screen to scarf. Designers should leverage nano-inks' expanded color gamut by incorporating Pantone Extended Gamut Coated color references when possible—particularly valuable for seasonal color stories demanding precise shade matching.

Pre-press calibration represents one of the most overlooked yet critical steps in the process. Daily calibration of print heads—including nozzle checks and alignment adjustments—prevents color banding and ensures uniform ink deposition. Weekly linearization tests that map actual ink output against digital color values create a feedback loop that maintains consistency across production runs. Many leading printers now include automated calibration systems that detect and correct color drift before it affects production quality.

During print execution, environmental controls significantly impact color development. Maintaining stable temperature (20-24°C) and relative humidity (55-65%) in the printing area prevents ink viscosity fluctuations that cause color density variations. For high-volume production, inline spectrophotometric measurement systems allow real-time color verification and adjustment, ensuring the first and thousandth scarf off the production line maintain identical color characteristics.

Post-printing processes complete the color optimization journey. For nano-ink prints, UV curing systems have largely replaced traditional heat-setting methods, locking in color instantly while reducing energy consumption by up to 40%. Follow-up washing with pH-neutral detergents removes excess pretreatment chemicals without affecting color integrity, while controlled tumble drying at low temperatures prevents fabric shrinkage that could distort printed patterns.

Industry Applications: Case Studies in Color Excellence

Nano-ink technology has delivered impressive results across various scarf market segments—from luxury fashion houses to sustainable accessory brands. Analyzing these success stories provides valuable insights for maximizing color vibrancy while addressing specific production challenges.

A premium silk scarf manufacturer that transitioned from traditional screen printing to nano-ink digital textile printing expanded their color palette by 45% while reducing production time by 60%. By implementing a comprehensive color management workflow with custom ICC profiles for each silk blend and regular calibration protocols, the brand achieved consistent color reproduction across multiple printing facilities—a critical factor for maintaining brand identity across global markets. Customer feedback highlighted particular appreciation for enhanced jewel tone depth and improved color fastness compared to previous products.

In the fast fashion sector, a major retailer utilized nano-ink technology's rapid setup capabilities to reduce time-to-market for seasonal scarf collections from weeks to days. Combining high-speed printing machines with quick-curing nano-inks created a responsive production model capable of delivering trend-inspired designs within 72 hours of design finalization. This agility improved inventory management and enabled limited-edition runs with unique color combinations that created customer urgency and exclusivity.

Sustainable accessory brands have found particular value in nano-ink technology's environmental benefits. A certified B Corp scarf manufacturer documented an 82% reduction in water usage and 35% lower carbon footprint after implementing nano-ink digital printing compared to traditional dye-sublimation processes. The improved color saturation allowed the brand to achieve their signature vibrant aesthetic using 20% less ink, further reducing environmental impact while maintaining the visual impact defining their product line. Third-party certification verified their nano-ink printed scarves met stringent Global Organic Textile Standard (GOTS) requirements for low-impact processing.

Troubleshooting Common Color Challenges in Nano-Ink Printing

Despite the advanced technology, digital scarf printing occasionally presents color consistency challenges requiring targeted troubleshooting. Understanding these common issues and solutions ensures minimal production disruption while maintaining quality standards.

Color shifting between production batches often stems from inconsistent fabric preparation rather than ink performance. When encountering unexpected hue variations, first verify pretreatment application uniformity using a spectrophotometer to measure surface pH levels across the fabric roll. Inconsistent pretreatment creates localized areas with different ink absorption rates, appearing as color blotches or stripes in the final print. Automated spray application systems with integrated moisture sensors help maintain consistent pretreatment coverage, eliminating this common issue.

Dull or muted colors despite using nano-ink technology typically indicate suboptimal curing conditions. UV curing systems require precise intensity and exposure time calibration to fully activate color development in nano-particle inks. When colors appear washed out, printing color swatches at varying UV intensities and measuring color values with a spectrophotometer reveals the optimal energy level for each color. Often, specific hues require slightly different curing parameters than standard settings.

Color bleeding on delicate fabrics like silk or cashmere blends usually traces to excessive ink laydown or improper pre-treatment. Nano-inks' superior color intensity achieves vibrant results with thinner ink layers, reducing bleeding potential. For particularly absorbent fabrics, adjusting the printer to apply a mist coat of clear pre-treatment before color application creates a controlled barrier that manages ink spread while maintaining color brightness—a technique that works especially well for intricate designs with fine lines and detailed patterns.

Metallic and iridescent color challenges represent a specialized area where nano-ink technology offers distinct advantages over conventional inks. Achieving consistent metallic effects requires precise control of nano-particle orientation during curing. When metallic finishes appear uneven or lack luster, adjusting the print head height to optimize ink droplet angle and implementing a two-stage curing process (initial low-temperature setting followed by final curing) typically resolves the issue. Leading ink manufacturers now offer specialized metallic nano-ink formulations with modified particle shapes that enhance light reflection for more consistent, brilliant metallic effects.

Strategic Implementation Recommendations for Fashion Brands

Fashion brands and accessory retailers looking to leverage nano-ink technology for scarf production require a strategic implementation approach to ensure optimal results while maximizing return on investment. Based on industry best practices and practical experience, these recommendations address key considerations from equipment selection to quality control systems.

When evaluating equipment investments, prioritize modular digital printing systems that allow future expansion over turnkey solutions with limited upgrade paths. The rapid evolution of nano-ink technology makes flexibility essential. Look for printers with upgradable print heads, expandable color stations, and open architecture supporting multiple ink formulations. While initial costs may be higher, this approach prevents premature obsolescence as new nano-ink formulations and printing technologies emerge. For brands producing fewer than 5,000 scarves monthly, entry-level industrial printers with 8-color capability offer an optimal balance of quality and investment, typically providing return on investment within 12-18 months through reduced production costs and expanded design capabilities.

Developing a comprehensive color management system creates a critical foundation for consistent results. This includes standardized workflows for design file preparation, regular calibration protocols for all equipment, and a master color library specific to your brand's color standards. Professional color measurement tools—including spectrophotometers and densitometers—provide objective quality control metrics that eliminate subjective evaluations. For multi-location operations, cloud-based color management software ensures consistent color standards across production facilities, proving particularly valuable for maintaining brand identity across global markets.

Staff training programs should extend beyond basic equipment operation to include color theory, ink chemistry, and advanced troubleshooting. Many ink manufacturers offer certification programs that ensure technical staff understand their specific nano-ink formulations and optimization for different fabrics and designs. Cross-training production personnel in both printing and quality control creates a more integrated production process where potential color issues get identified and addressed earlier. Regular workshops on new color management techniques and nano-ink developments help maintain technical expertise as the technology evolves.

For brands focusing on sustainability credentials, nano-ink technology offers significant advantages worth integrating into marketing communications. Documenting and verifying environmental benefits—reduced water usage, lower energy consumption, and minimized chemical waste—provides valuable content for sustainability reports and product storytelling. Third-party certifications for both inks and production processes enhance credibility with environmentally conscious consumers. Additionally, digital textile printing technology's ability to produce smaller batches economically supports circular economy principles by reducing overproduction and inventory waste—a message that resonates increasingly with modern consumers.

Establishing clear quality control metrics specific to nano-ink printed scarves ensures consistent product standards. Key performance indicators should include color fastness to washing and light exposure, rub resistance, and color consistency across production runs. Statistical process control methods monitoring these metrics identify trends before they become quality issues, reducing waste and rework. For luxury brands, developing a signature color standard serves as a production quality benchmark, ensuring consistency while creating a unique selling proposition that differentiates products in the marketplace.

Nano-ink technology has transformed color expression possibilities in digital scarf printing, offering fashion brands unprecedented vibrancy, consistency, and design flexibility. By understanding the technical foundations, implementing optimized production processes, and following industry best practices, brands can leverage this textile print innovation effectively—resulting in distinctive accessories that stand out in a crowded marketplace while meeting modern fashion production demands. As the technology continues evolving, ongoing learning and process refinement will keep your brand at the forefront of digital textile printing innovation.