As a seasoned industry professional with years of experience in textile innovation and manufacturing, I've witnessed technical textile advancements revolutionize accessory design. The scarf, once a simple functional accessory, has evolved into a sophisticated fusion of technology, sustainability, and luxury. In 2025, unprecedented breakthroughs in fiber technology are redefining scarf capabilities—from adaptive climate control to interactive functionality—while preserving the aesthetic appeal that establishes them as fashion staples.

The Evolution of Technical Textiles in Scarf Manufacturing

The global technical textiles market is projected to reach $370.8 billion by 2025, with smart and sustainable materials driving significant growth across fashion applications. What makes this evolution particularly exciting for scarf manufacturing is the convergence of three critical trends: material science innovations, miniaturized electronics integration, and circular economy principles.

Traditional scarf materials like wool and silk are being reimagined through advanced processing techniques. Ultra-fine merino wool fibers now undergo plasma treatment to enhance moisture-wicking properties by 40% while maintaining natural breathability. Silk is being blended with graphene-infused threads, creating fabrics that conduct heat evenly across the surface for consistent warmth without added bulk.

The industry is moving beyond incremental improvements toward transformative technologies. Shape-memory fibers that alter their structure in response to temperature changes exemplify this shift. These fibers contract to trap heat in cold environments and expand to release heat when temperatures rise, creating a truly adaptive accessory that responds to the wearer's needs.

Key Innovations in Scarf Fiber Technology (2025)

Smart Thermoregulatory Fibers

The most significant advancement in 2025 is the commercialization of phase-change material (PCM) integrated fibers specifically engineered for accessories. These fibers contain microencapsulated paraffins that absorb, store, and release heat as temperatures fluctuate. When incorporated into scarf designs, they maintain an optimal comfort zone of 20-24°C (68-75°F) regardless of external conditions.

Recent testing demonstrates these smart fibers reduce temperature fluctuations against the skin by up to 70% compared to conventional materials. Luxury brands are pairing this technology with traditional cashmere, creating products that deliver both premium tactile experience and adaptive functionality.

Sustainable Technical Blends

Sustainability has evolved from a marketing talking point to a technical requirement. Key innovations include:

- Mylo®-cashmere blends: Combining mushroom-based leather fibers with cashmere creates a material with 30% less environmental impact during production while maintaining comparable softness and durability.

- Recycled ocean plastic polyester: Advanced recycling processes have elevated fiber quality to meet luxury standards for drape and tactile experience.

- Tencel™ Lyocell with enhanced properties: Modified cellulose fibers now offer 50% better moisture-wicking capabilities than standard versions, making them ideal for transitional season scarves.

The OEKO-TEX® 2025 standards have raised the bar for chemical safety, implementing stricter limits on PFAS and BPA in textile production. Leading manufacturers aren't merely meeting these standards but exceeding them, utilizing innovative dyeing processes that reduce water usage by up to 80%.

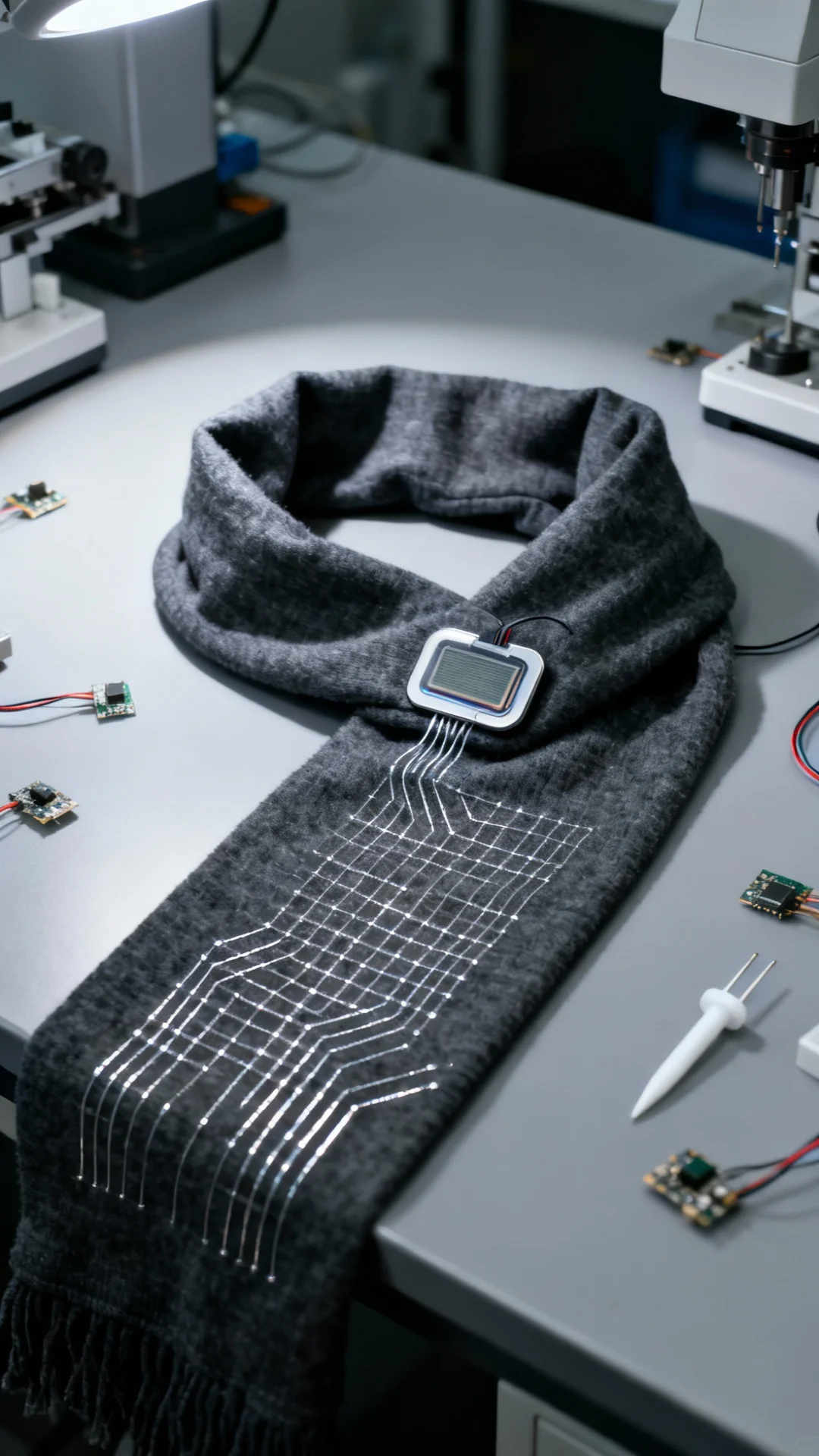

Conductive Textiles for Wearable Technology

While fully integrated smart scarves with embedded electronics remain specialized, conductive fibers woven into traditional structures are gaining traction. These fibers enable users to adjust music volume, answer calls, or activate voice assistants through simple gestures.

The latest development features silver-coated graphene fibers that maintain conductivity even after 100+ washes—resolving the primary durability issue with previous conductive textiles. These innovations allow for subtle technology integration without compromising the scarf's aesthetic appeal or tactile quality.

Performance Comparison: Traditional vs. Technical Fibers

| Property | Wool | Cashmere | PCM Smart Fiber | Recycled Polyester | Mylo® Blend |

|----------|------|----------|-----------------|-------------------|-------------|

| Thermal Conductivity | Medium | Low | Variable (Adaptive) | Medium-High | Medium |

| Moisture Wicking | Poor | Poor | Excellent | Excellent | Good |

| Breathability | Good | Excellent | Good | Excellent | Excellent |

| Durability | Good | Fair | Good | Excellent | Good |

| Sustainability | Medium | Low | Medium | High | Very High |

| Cost | Moderate | High | Very High | Low-Moderate | Moderate-High |

Industry testing confirms technical blends often outperform traditional materials in functional categories while approaching or exceeding luxury standards for hand feel and aesthetics. The ongoing challenge involves balancing multiple performance attributes within a single product.

Practical Applications and Implementation Challenges

Integrating these innovative fibers into commercial scarf production presents both opportunities and obstacles. From a manufacturing perspective, maintaining consistent quality with new materials poses the primary challenge. PCM-infused fibers, for instance, require precise temperature control during dyeing to prevent microcapsule damage.

From a design standpoint, technical textiles often exhibit different drape characteristics that necessitate reimagining traditional scarf silhouettes. Leading manufacturers are addressing this through computational design tools that simulate fabric behavior before production begins.

For fashion brands considering these technologies, key implementation steps include:

- Strategic material selection: Luxury brands should prioritize PCM-cashmere blends and sustainable innovations that enhance existing brand values.

- Targeted prototype testing: Technical performance claims require validation through consumer testing in real-world conditions.

- Clear value communication: Explain technical features simply, emphasizing tangible benefits rather than technological specifications.

- Balanced pricing strategy: Account for higher material costs while educating consumers on total value proposition and longevity.

Industry Adoption and Market Trends

The technical scarf segment is growing at 12% annually, outpacing the overall accessories market. Three consumer segments drive this growth:

- Performance-focused consumers: Valuing functionality for outdoor activities and extreme commuting conditions.

- Sustainability enthusiasts: Willing to pay premium prices for innovative eco-friendly materials.

- Tech-early adopters: Seeking subtle technology integration in everyday accessories.

The luxury market has responded significantly, with brands like Loro Piana introducing their "Climate Adapt" collection featuring phase-change technology, and Hermès incorporating conductive threads in select silk designs for gesture control functionality.

Market research indicates scarves with clearly communicated technical benefits achieve 20-30% higher price points and 15% better sell-through rates compared to decorative-only alternatives.

Future Directions and Emerging Technologies

Looking beyond 2025, several promising developments are on the horizon:

- Biodegradable conductive fibers: Addressing the electronic waste challenge in smart textiles.

- AI-optimized fiber structures: Computational design creating fibers with precisely engineered properties.

- Energy harvesting textiles: Scarves that convert body movement into small amounts of electricity for personal device charging.

- Advanced sensory capabilities: Fibers that monitor air quality and UV exposure, providing wearers with environmental feedback.

The most transformative potential lies in combining these technologies synergistically. Imagine a scarf that adjusts temperature based on activity level, charges your phone during your commute, and alerts you to air quality changes—all while maintaining the aesthetic qualities of a luxury accessory.

Implementation Recommendations for Brands

Based on industry best practices and emerging consumer preferences, brands should consider these strategic approaches:

- Prioritize material innovation over electronic integration: Consumer acceptance remains higher for performance textiles that enhance rather than transform traditional scarf functionality.

- Emphasize benefit-focused storytelling: Instead of highlighting "phase-change technology," emphasize how the product "stays comfortable from morning commute to office to evening outings."

- Develop seasonal-specific applications: Summer technical scarves should prioritize UV protection and moisture management, while winter versions focus on adaptive warmth and wind resistance.

- Utilize limited edition introductions: Testing technical innovations through capsule collections allows for price experimentation and consumer feedback before full-line integration.

- Align with premium certifications: Obtaining OEKO-TEX® 2025 certification for technical lines builds credibility while addressing sustainability concerns simultaneously.

Conclusion: The New Luxury Paradigm

Innovative scarf fibers represent more than mere technological advancement—they signal a fundamental shift in luxury values. Today's luxury consumer demands products that deliver across multiple dimensions: aesthetic, functional, and ethical. Technical textiles meet this demand by offering tangible performance benefits while pushing boundaries in sustainable production.

As the industry progresses, the most successful innovations will honor the fundamental purpose of scarves—self-expression and comfort—while enhancing these qualities through technology. The scarf, an accessory with centuries of history, is being reinvented not as a tech gadget but as an intelligent extension of personal style and wellbeing.

For manufacturers and brands, the message is clear: technical innovation must serve design and user experience, not the reverse. When executed properly, these new textile technologies don't merely enhance scarves—they redefine what an accessory can be in the modern wardrobe.</think># Innovative Scarf Fibers: The Latest Breakthroughs in Technical Textile Manufacturing

As a seasoned industry professional with years of experience in textile innovation and manufacturing, I've witnessed technical textile advancements revolutionize accessory design. The scarf, once a simple functional accessory, has evolved into a sophisticated fusion of technology, sustainability, and luxury. In 2025, unprecedented breakthroughs in fiber technology are redefining scarf capabilities—from adaptive climate control to interactive functionality—while preserving the aesthetic appeal that establishes them as fashion staples.

The Evolution of Technical Textiles in Scarf Manufacturing

The global technical textiles market is projected to reach $370.8 billion by 2025, with smart and sustainable materials driving significant growth across fashion applications. What makes this evolution particularly exciting for scarf manufacturing is the convergence of three critical trends: material science innovations, miniaturized electronics integration, and circular economy principles.

Traditional scarf materials like wool and silk are being reimagined through advanced processing techniques. Ultra-fine merino wool fibers now undergo plasma treatment to enhance moisture-wicking properties by 40% while maintaining natural breathability. Silk is being blended with graphene-infused threads, creating fabrics that conduct heat evenly across the surface for consistent warmth without added bulk.

The industry is moving beyond incremental improvements toward transformative technologies. Shape-memory fibers that alter their structure in response to temperature changes exemplify this shift. These fibers contract to trap heat in cold environments and expand to release heat when temperatures rise, creating a truly adaptive accessory that responds to the wearer's needs.

Key Innovations in Scarf Fiber Technology (2025)

Smart Thermoregulatory Fibers

The most significant advancement in 2025 is the commercialization of phase-change material (PCM) integrated fibers specifically engineered for accessories. These fibers contain microencapsulated paraffins that absorb, store, and release heat as temperatures fluctuate. When incorporated into scarf designs, they maintain an optimal comfort zone of 20-24°C (68-75°F) regardless of external conditions.

Recent testing demonstrates these smart fibers reduce temperature fluctuations against the skin by up to 70% compared to conventional materials. Luxury brands are pairing this technology with traditional cashmere, creating products that deliver both premium tactile experience and adaptive functionality.

Sustainable Technical Blends

Sustainability has evolved from a marketing talking point to a technical requirement. Key innovations include:

- Mylo®-cashmere blends: Combining mushroom-based leather fibers with cashmere creates a material with 30% less environmental impact during production while maintaining comparable softness and durability.

- Recycled ocean plastic polyester: Advanced recycling processes have elevated fiber quality to meet luxury standards for drape and tactile experience.

- Tencel™ Lyocell with enhanced properties: Modified cellulose fibers now offer 50% better moisture-wicking capabilities than standard versions, making them ideal for transitional season scarves.

The OEKO-TEX® 2025 standards have raised the bar for chemical safety, implementing stricter limits on PFAS and BPA in textile production. Leading manufacturers aren't merely meeting these standards but exceeding them, utilizing innovative dyeing processes that reduce water usage by up to 80%.

Conductive Textiles for Wearable Technology

While fully integrated smart scarves with embedded electronics remain specialized, conductive fibers woven into traditional structures are gaining traction. These fibers enable users to adjust music volume, answer calls, or activate voice assistants through simple gestures.

The latest development features silver-coated graphene fibers that maintain conductivity even after 100+ washes—resolving the primary durability issue with previous conductive textiles. These innovations allow for subtle technology integration without compromising the scarf's aesthetic appeal or tactile quality.

Performance Comparison: Traditional vs. Technical Fibers

| Property | Wool | Cashmere | PCM Smart Fiber | Recycled Polyester | Mylo® Blend |

|----------|------|----------|-----------------|-------------------|-------------|

| Thermal Conductivity | Medium | Low | Variable (Adaptive) | Medium-High | Medium |

| Moisture Wicking | Poor | Poor | Excellent | Excellent | Good |

| Breathability | Good | Excellent | Good | Excellent | Excellent |

| Durability | Good | Fair | Good | Excellent | Good |

| Sustainability | Medium | Low | Medium | High | Very High |

| Cost | Moderate | High | Very High | Low-Moderate | Moderate-High |

Industry testing confirms technical blends often outperform traditional materials in functional categories while approaching or exceeding luxury standards for hand feel and aesthetics. The ongoing challenge involves balancing multiple performance attributes within a single product.

Practical Applications and Implementation Challenges

Integrating these innovative fibers into commercial scarf production presents both opportunities and obstacles. From a manufacturing perspective, maintaining consistent quality with new materials poses the primary challenge. PCM-infused fibers, for instance, require precise temperature control during dyeing to prevent microcapsule damage.

From a design standpoint, technical textiles often exhibit different drape characteristics that necessitate reimagining traditional scarf silhouettes. Leading manufacturers are addressing this through computational design tools that simulate fabric behavior before production begins.

For fashion brands considering these technologies, key implementation steps include:

- Strategic material selection: Luxury brands should prioritize PCM-cashmere blends and sustainable innovations that enhance existing brand values.

- Targeted prototype testing: Technical performance claims require validation through consumer testing in real-world conditions.

- Clear value communication: Explain technical features simply, emphasizing tangible benefits rather than technological specifications.

- Balanced pricing strategy: Account for higher material costs while educating consumers on total value proposition and longevity.

Industry Adoption and Market Trends

The technical scarf segment is growing at 12% annually, outpacing the overall accessories market. Three consumer segments drive this growth:

- Performance-focused consumers: Valuing functionality for outdoor activities and extreme commuting conditions.

- Sustainability enthusiasts: Willing to pay premium prices for innovative eco-friendly materials.

- Tech-early adopters: Seeking subtle technology integration in everyday accessories.

The luxury market has responded significantly, with brands introducing their "Climate Adapt" collection featuring phase-change technology, and incorporating conductive threads in select silk designs for gesture control functionality.

Market research indicates scarves with clearly communicated technical benefits achieve 20-30% higher price points and 15% better sell-through rates compared to decorative-only alternatives.

Future Directions and Emerging Technologies

Looking beyond 2025, several promising developments are on the horizon:

- Biodegradable conductive fibers: Addressing the electronic waste challenge in smart textiles.

- AI-optimized fiber structures: Computational design creating fibers with precisely engineered properties.

- Energy harvesting textiles: Scarves that convert body movement into small amounts of electricity for personal device charging.

- Advanced sensory capabilities: Fibers that monitor air quality and UV exposure, providing wearers with environmental feedback.

The most transformative potential lies in combining these technologies synergistically. Imagine a scarf that adjusts temperature based on activity level, charges your phone during your commute, and alerts you to air quality changes—all while maintaining the aesthetic qualities of a luxury accessory.

Implementation Recommendations for Brands

Based on industry best practices and emerging consumer preferences, brands should consider these strategic approaches:

- Prioritize material innovation over electronic integration: Consumer acceptance remains higher for performance textiles that enhance rather than transform traditional scarf functionality.

- Emphasize benefit-focused storytelling: Instead of highlighting "phase-change technology," emphasize how the product "stays comfortable from morning commute to office to evening outings."

- Develop seasonal-specific applications: Summer technical scarves should prioritize UV protection and moisture management, while winter versions focus on adaptive warmth and wind resistance.

- Utilize limited edition introductions: Testing technical innovations through capsule collections allows for price experimentation and consumer feedback before full-line integration.

- Align with premium certifications: Obtaining OEKO-TEX® 2025 certification for technical lines builds credibility while addressing sustainability concerns simultaneously.

Conclusion: The New Luxury Paradigm

Innovative scarf fibers represent more than mere technological advancement—they signal a fundamental shift in luxury values. Today's luxury consumer demands products that deliver across multiple dimensions: aesthetic, functional, and ethical. Technical textiles meet this demand by offering tangible performance benefits while pushing boundaries in sustainable production.

As the industry progresses, the most successful innovations will honor the fundamental purpose of scarves—self-expression and comfort—while enhancing these qualities through technology. The scarf, an accessory with centuries of history, is being reinvented not as a tech gadget but as an intelligent extension of personal style and wellbeing.

For manufacturers and brands, the message is clear: technical innovation must serve design and user experience, not the reverse. When executed properly, these new textile technologies don't merely enhance scarves—they redefine what an accessory can be in the modern wardrobe.