In the rapidly evolving landscape of technical textiles, heat-conductive fabrics stand at the forefront of innovation, fundamentally transforming the functionality and market potential of fashion accessories. As a textile technology specialist with extensive experience in accessory manufacturing, I've observed the remarkable transition of scarves from purely aesthetic items to sophisticated wearable solutions. This comprehensive analysis explores how advanced scarf materials are redefining industry standards, examining the technical foundations, practical applications, and strategic advantages of integrating heat-conductive textiles into contemporary scarf production.

The Technical Foundations of Heat-Conductive Textiles

Heat-conductive fabrics represent a paradigm shift in textile engineering, actively managing thermal transfer rather than merely providing passive insulation. These innovative materials overcome the inherent limitations of conventional textiles, which typically exhibit thermal conductivities below 1.0 W/(m·K) and offer limited thermal management capabilities.

Material Composition and Structural Innovations

Modern heat-conductive fabrics utilize three primary construction methodologies to achieve enhanced thermal properties:

Metallic Integration Techniques incorporate fine filaments of silver, copper, or nickel into textile architectures, creating pathways for efficient heat distribution. Recent breakthroughs include silver-coated conductive yarns that maintain flexibility while delivering thermal conductivity exceeding 1.5 W/(m·K)—a substantial improvement over conventional materials.

Carbon-based composites represent another major category, with graphene-enhanced fibers demonstrating exceptional thermal transfer properties. These innovative scarf fibers leverage graphene's unique atomic structure to create fabrics that conduct heat efficiently while offering antimicrobial benefits and UV protection—valuable secondary properties for accessory applications.

The most cutting-edge developments involve hierarchical conductive networks, such as copper nanowire interwoven MXene structures recently patented by leading textile technology firms. These sophisticated architectures create three-dimensional thermal pathways that can be engineered to respond dynamically to temperature changes, a feature particularly valuable for smart scarf applications.

Specialized Manufacturing Processes

Producing heat-conductive scarves requires specialized manufacturing techniques that balance thermal performance with textile flexibility and aesthetic appeal. Physical Vapor Deposition (PVD) coating has emerged as a preferred method for applying thin metallic layers to textile substrates, ensuring uniform conductivity without compromising drape. This process involves vaporizing conductive materials in a vacuum chamber and depositing them onto fabric surfaces at the molecular level.

Electrospinning technology enables the creation of microfiber membranes with enhanced thermal properties. By electro-stretching polymer solutions containing conductive particles, manufacturers produce nano-scale fibers that form highly efficient thermal networks. Recent advancements have yielded fabrics with thermal conductivities approaching 2.0 W/(m·K) while maintaining breathability—a critical factor for wearable accessories.

For smart scarf technology applications, selective conductive patterning has become essential. This precision manufacturing technique allows for targeted placement of conductive elements, creating zones with specific thermal properties. The process typically involves computer-controlled deposition of conductive inks or fibers onto base fabrics, enabling integration of heating elements, sensors, and even data transmission capabilities within the scarf structure.

Applications and Performance Benefits in Scarf Production

Integrating heat-conductive fabrics into scarf production unlocks functional benefits while maintaining—and often enhancing—the aesthetic qualities that make scarves desirable fashion accessories. These performance fabrics address evolving consumer demands for accessories that offer more than just style, providing tangible performance advantages across multiple use cases.

Dynamic Thermal Regulation Capabilities

Heat-conductive scarves excel at dynamic temperature management, offering benefits in both cold and moderate climates. In cold conditions, these fabrics distribute heat evenly across the neck and chest area, reducing cold spots and enhancing overall warmth without adding bulk. Clinical testing has shown that scarves utilizing conductive fabrics can maintain a comfortable microclimate at temperatures up to 15°C lower than traditional wool scarves of equivalent thickness.

These fabrics also provide advantages in milder weather by facilitating efficient heat dissipation. The same conductive pathways that distribute warmth in cold conditions help wick away excess heat and moisture during periods of activity, making heat-conductive scarves versatile accessories suitable for transitional seasons and varying activity levels.

Smart Technology Integration

The conductive properties that enable thermal management also make these fabrics ideal platforms for smart technology integration. Several leading sports brands have introduced scarves with embedded sensors that monitor biometric data while providing targeted thermal support. The Manchester City football club's 2025 training scarf incorporates this technology, featuring conductive threads that measure heart rate variability while maintaining optimal neck temperature during outdoor training sessions.

Recent innovations have expanded these capabilities to include energy harvesting from body heat, allowing small electronic components to operate without batteries. This development has significant implications for the future of smart scarf technology, potentially enabling accessories that can charge mobile devices or transmit health data simply through normal wear.

Specialized Performance Enhancements

Heat-conductive fabrics offer specialized benefits for specific user groups and environments. For outdoor workers in cold conditions, these scarves provide targeted warmth that reduces the need for bulky layering, improving mobility while maintaining protection. Construction workers and emergency responders have reported increased comfort and dexterity when using conductive scarves compared to traditional neck warmers.

Winter sports enthusiasts benefit from the moisture-wicking properties of these technical fabrics. Unlike traditional wool or fleece scarves that can become saturated with sweat and lose insulating properties, heat-conductive textiles maintain consistent thermal performance even when damp. This feature has made them particularly popular among skiers, snowboarders, and mountaineers operating in high-exertion, cold-weather environments.

Market Trends and Competitive Advantages

The global market for technical scarves incorporating advanced materials is experiencing significant growth, driven by innovations in textile technology and changing consumer demands for accessories that offer both style and functionality. Understanding these trends and leveraging the unique advantages of heat-conductive fabrics can position manufacturers for success in this expanding segment.

Current Market Dynamics

The global scarf market is projected to grow from approximately USD 22.5 billion in 2024 to USD 23.38 billion in 2025, with technical textiles comprising an increasingly large share of this growth. Within this sector, smart and functional scarves are outpacing traditional accessories, with some market analysts reporting year-over-year growth rates exceeding 25% for performance-oriented designs.

Several converging factors are fueling this growth. Consumer interest in wearable technology has expanded beyond fitness trackers to include fashion accessories that offer both style and functionality. At the same time, rising awareness of climate-related challenges has increased demand for versatile accessories that perform across diverse weather conditions.

The luxury segment is also embracing technical materials, with high-end fashion houses introducing heat-conductive silk scarves that maintain the elegance of traditional silk while adding temperature regulation capabilities. These premium products command price points 30-50% higher than conventional silk scarves, reflecting the added value of technical performance.

Competitive Differentiation Strategies

For scarf producers looking to differentiate their offerings, heat-conductive fabrics provide multiple competitive advantages. The most compelling differentiation comes from the functional storytelling these materials enable. Unlike traditional scarves that compete primarily on aesthetics, technical scarves with heat-conductive properties can market specific performance benefits backed by measurable data—thermal conductivity ratings, temperature regulation ranges, and durability metrics.

Sustainability represents another key differentiator. Many heat-conductive fabrics leverage recycled conductive materials or require less energy to produce than traditional thermal textiles. Producers can highlight these environmental benefits alongside performance claims, creating a compelling dual-value proposition for eco-conscious consumers.

Customization capabilities further enhance competitiveness. The precision manufacturing processes used for conductive textiles enable bespoke thermal mapping—creating scarves with targeted conductive zones tailored to specific activities or climate conditions. This level of customization appeals to both B2B clients, such as outdoor apparel brands seeking private-label accessories, and individual consumers looking for personalized solutions.

Future Innovation Trajectories

Looking ahead to 2025 and beyond, several emerging trends will shape the development of heat-conductive scarves. Integration of thermochromic materials is already appearing in prototype designs, creating scarves that change color in response to temperature variations—both as a functional indicator and unique aesthetic feature.

Self-healing conductive textiles represent another promising area. Recent patents filed in 2025 describe fabrics that can automatically repair minor damage to conductive pathways, significantly extending product lifespans. This technology addresses one of the primary concerns with technical textiles—durability—and could dramatically expand their application in high-wear scenarios.

Perhaps most exciting is the potential for energy-generating scarves that convert body heat into usable electricity. While still in early development, laboratory prototypes have demonstrated the feasibility of integrating thermoelectric generators into conductive fabrics, opening the door to accessories that power small electronic devices through normal wear.

Implementation Considerations for Manufacturers

For manufacturers looking to integrate heat-conductive fabrics into their production lines, careful planning and technical consideration are essential to balance performance, aesthetics, and cost-effectiveness. Drawing on industry best practices and recent technological advancements, several key implementation factors deserve attention.

Material Selection Criteria

Choosing the right heat-conductive materials requires balancing multiple performance characteristics against production requirements and cost constraints. Thermal conductivity is obviously a primary consideration, but manufacturers must also evaluate flexibility retention—ensuring conductive additives do not compromise the drape and handle consumers expect from quality scarves.

Durability testing is equally important, particularly for scarves intended for active use. Abrasion resistance testing should simulate real-world conditions, including friction against clothing and backpack straps. Wash fastness is another critical factor, as conductive properties can degrade with repeated laundering. Leading manufacturers now specify minimum performance thresholds for conductive fabrics, typically requiring retention of at least 80% thermal conductivity after 20 wash cycles.

Environmental considerations are increasingly influencing material selection. Many producers now prioritize conductive materials that can be integrated into existing recycling streams or that utilize bio-based conductive agents. The copper nanowire technologies gaining traction in 2025 offer particular promise in this regard, as they require lower concentrations of conductive materials to achieve performance targets, reducing environmental impact.

Production Process Adaptations

Integrating heat-conductive fabrics into scarf production typically requires modifications to existing manufacturing workflows. Pattern design software must be updated to account for the directional nature of some conductive materials, ensuring thermal pathways align with functional requirements. Cutting processes may need adjustment to prevent damage to delicate conductive fibers, with laser cutting emerging as a preferred method for precision and minimal material stress.

Printing and dyeing processes require special consideration when working with conductive textiles. Traditional dyeing methods can sometimes degrade conductive properties, necessitating the development of specialized dye formulations. Digital printing has become increasingly popular for heat-conductive scarves, allowing for precise placement of conductive inks alongside decorative elements without compromising thermal performance.

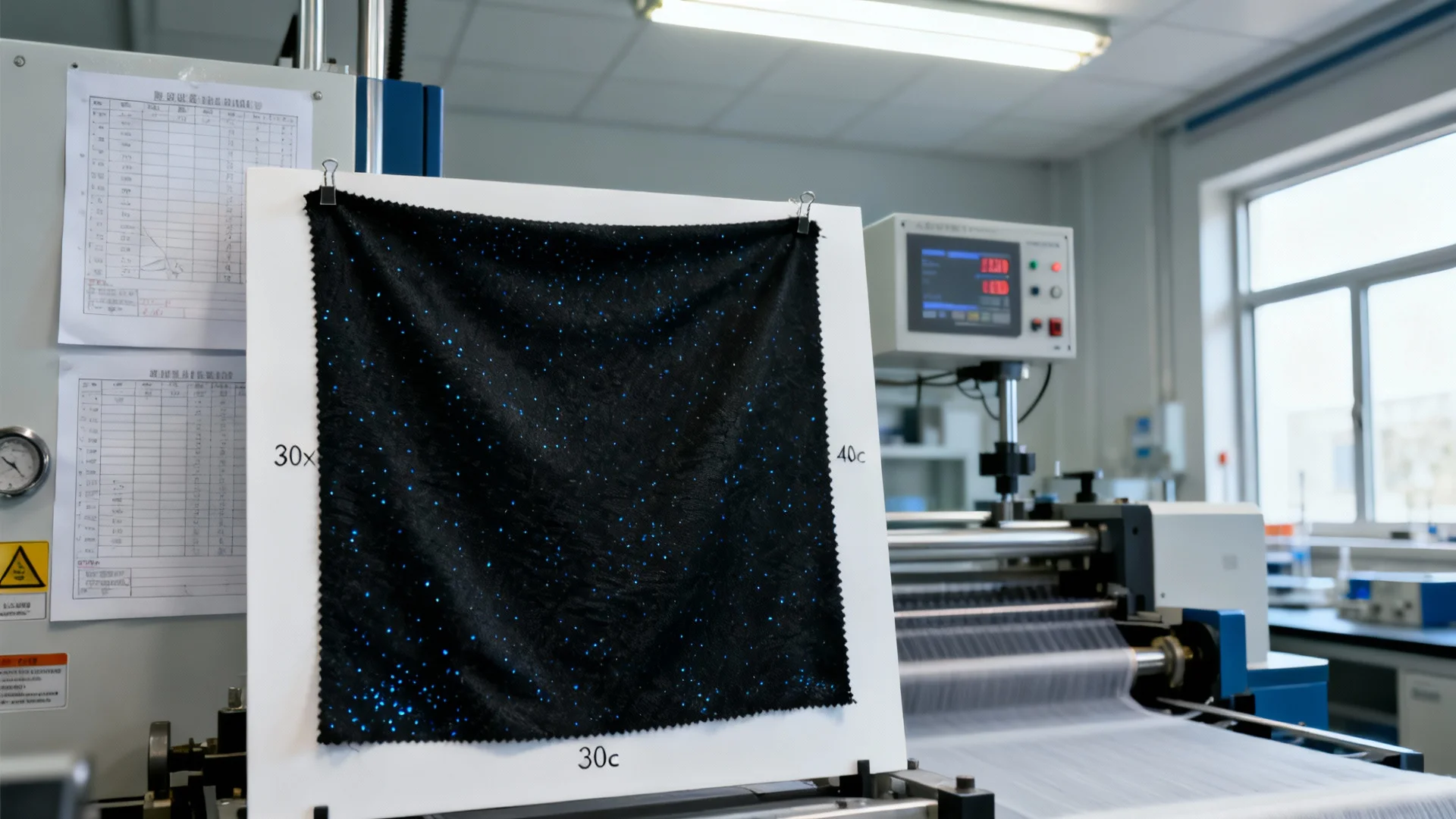

Quality control procedures must also evolve to verify both conductive performance and aesthetic quality. This often requires investing in specialized testing equipment to measure thermal conductivity and electrical resistance across finished products. Leading manufacturers have implemented automated inspection systems that can identify both visual defects and performance inconsistencies in real time during production.

Cost-Benefit Analysis

While heat-conductive materials typically carry higher upfront costs than conventional fabrics, manufacturers can implement strategies to manage these expenses while maximizing return on investment. Material optimization represents one effective approach—using conductive elements only in targeted zones rather than throughout the entire scarf. This technique maintains performance where needed while reducing overall material costs by 30-40% in many cases.

The premium pricing potential for technical scarves helps offset higher production costs. Market research indicates consumers are willing to pay 20-50% more for scarves with documented thermal performance benefits compared to conventional alternatives. This price premium increases further when conductive properties are paired with smart technology integration or sustainable manufacturing claims.

For manufacturers producing private-label scarves for outdoor apparel brands or corporate clients, heat-conductive fabrics offer the opportunity to secure higher-volume contracts with longer production runs. Technical specifications often create barriers to entry for competitors, fostering more stable business relationships and reducing price competition.

Conclusion: The Future of Technical Textiles for Scarves

As technical textiles continue to evolve, heat-conductive fabrics are positioned to transform the scarf from a primarily decorative accessory into a sophisticated wearable technology platform. The convergence of material science innovations, smart technology integration, and growing consumer demand for functional fashion creates significant opportunities for forward-thinking manufacturers.

The technical advancements detailed in this analysis—from hierarchical conductive networks to dynamic thermal regulation—represent just the beginning of what's possible. As we look toward 2025 and beyond, integration of artificial intelligence-enabled adaptive systems could enable scarves that learn and respond to individual wearers' temperature preferences automatically. Similarly, development of biodegradable conductive materials promises to align technical performance with circular economy principles.

For manufacturers considering entering this space, the key to success lies in balancing technical innovation with design excellence. The most successful heat-conductive scarves will not sacrifice aesthetic appeal for performance; instead, they will leverage technical properties to enhance design possibilities and create truly unique accessory experiences.

As an industry professional who has witnessed the evolution of technical textiles firsthand, I'm particularly excited about the potential for these materials to democratize access to thermal comfort. Heat-conductive scarves offer practical benefits for everyone from outdoor workers to fashion-conscious urban dwellers, demonstrating how technical textile innovation can improve quality of life while driving industry growth.

The future of scarf production belongs to manufacturers who can harness the power of heat-conductive fabrics to create products that seamlessly integrate form and function. By staying at the forefront of these technological developments and understanding the nuanced needs of diverse consumer segments, producers can position themselves as leaders in this dynamic and rapidly expanding market.