In the competitive landscape of luxury textile manufacturing, digital textile printing has emerged as a transformative technology, offering unprecedented design precision, customization capabilities, and production efficiency. As fashion houses and retailers demand consistent excellence across high-volume production runs, implementing robust quality control measures has become imperative for maintaining brand reputation and ensuring customer satisfaction.

This comprehensive technical guide outlines industry-leading quality control protocols specifically optimized for digital textile printing on scarf fabrics. Based on 2025 technological advancements and refined best practices, these methodologies span the entire production workflow—from pre-production material testing to post-printing inspection—ensuring every scarf meets the most stringent standards for color accuracy, durability, and aesthetic perfection.

The Evolving Quality Landscape in Digital Textile Printing

The global digital textile printing market continues its robust expansion at a 7.32% compound annual growth rate, projected to sustain this trajectory through 2030. This growth is fueled by evolving consumer preferences for personalized products and the fashion industry's accelerating shift toward sustainable production methods. Within this dynamic environment, scarf manufacturers face unique quality challenges due to the delicate nature of their products, often utilizing luxury materials like silk, cashmere, and fine wool that require specialized handling and printing techniques.

Critical quality parameters in digital scarf printing include color consistency across production runs, edge definition of printed patterns, color fastness to various environmental factors, and preservation of the fabric's inherent hand feel after printing. The technological advancements of 2025 have introduced new quality control variables, including AI-powered color management systems, IoT-enabled production monitoring, and nano-engineered inks that deliver enhanced vibrancy and durability.

Fashion accessories retailers and boutique buyers increasingly prioritize suppliers with rigorous quality control processes. A recent industry survey revealed that 87% of respondents identified "consistent print quality" as a primary factor when selecting scarf suppliers, while 76% cited "color fastness guarantees" as critical purchasing considerations. These findings underscore the strategic importance of implementing systematic quality control throughout the digital printing workflow.

Pre-Production Quality Control Foundations

Effective quality control begins long before the first print is executed. The pre-production phase establishes the essential foundation for consistent results by addressing both material characteristics and equipment calibration.

Material testing protocols ensure optimal compatibility between fabrics and digital printing processes. Each scarf material—whether silk, wool, cotton, or specialized synthetic blend—possesses unique absorbency, surface tension, and thermal properties that directly impact ink adhesion and color development. Standard tests measure fabric weight (grams per square meter), thread count, and surface smoothness—all critical factors influencing print resolution and ink penetration.

For luxury silk scarves, precise moisture content evaluation is particularly critical. Ideal levels should be maintained between 6-8% for optimal ink receptivity. Deviations from this range can cause irregular color absorption and unsightly variations across print runs. Advanced textile laboratories now utilize near-infrared spectroscopy to quickly assess moisture levels and other material properties without compromising valuable fabrics.

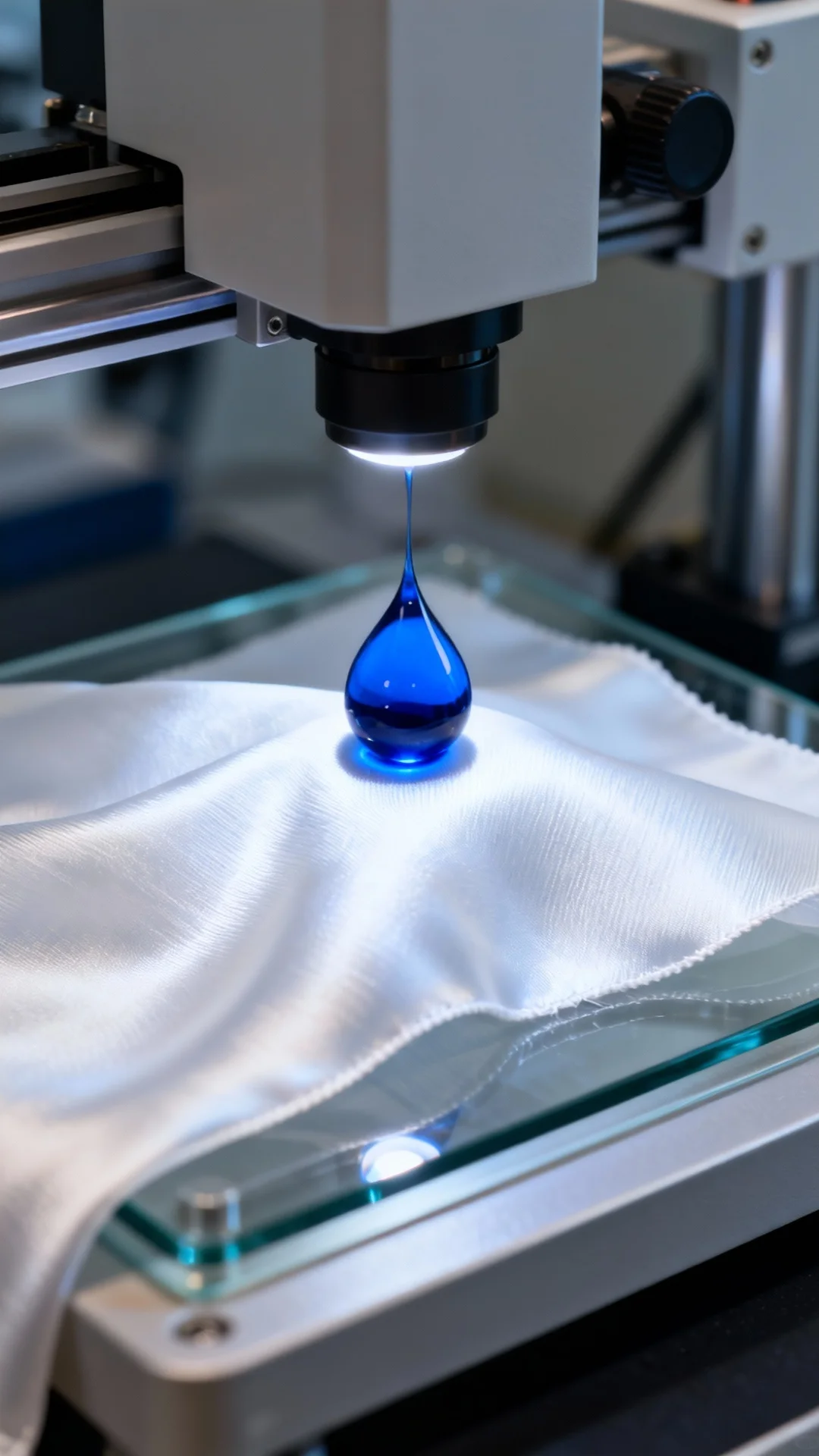

Ink formulation verification represents another crucial pre-production quality checkpoint. The latest nano-ink technologies feature particle sizes as small as 50-100 nanometers, requiring precise viscosity control—typically 12-18 cP (centipoise) for piezoelectric print heads. Ink batches undergo rigorous color consistency testing using spectrophotometric analysis, ensuring Delta E values (color difference measurements) remain below 1.0 for critical color matches.

Equipment calibration has evolved significantly with smart technology integration. Modern high-speed printing machines feature automated calibration routines that adjust print head alignment, droplet size, and ink flow rates based on specific fabric characteristics. Daily maintenance protocols include comprehensive nozzle performance tests to detect clogs or misfiring nozzles that could cause printing defects. Calibration must also account for environmental factors, with print room temperature maintained at 20-24°C (68-75°F) and relative humidity between 50-60% to ensure consistent ink behavior.

Design file optimization serves as the final pre-production quality control checkpoint. Files must account for the specific fabric's stretch characteristics and potential shrinkage during post-printing treatments. For scarves featuring intricate patterns requiring precise alignment across seams or folds, designers should implement a minimum 3mm bleed area around all elements. Quality control personnel verify that files meet the printer's resolution requirements—typically 300dpi for fine detail reproduction—and that appropriate color profiles are properly embedded for accurate translation from digital design to physical fabric.

In-Process Quality Control Monitoring

Transitioning from pre-production to active printing necessitates continuous quality control monitoring to identify and address issues immediately. Modern digital printing facilities combine sophisticated automated systems with specialized human inspection to maintain optimal quality throughout production runs.

Real-time process monitoring has been transformed by IoT (Internet of Things) technology integration. Today's smart printing machines incorporate advanced sensors that track ink temperature, print head pressure, substrate tension, and curing oven temperature. These sensors feed data to centralized quality management systems that alert operators to potential issues before they impact print quality. For instance, sudden ink temperature deviations might indicate circulation system problems that could cause inconsistent color application if not addressed immediately.

Despite technological advancements, visual inspection remains essential. Trained quality control personnel examine printed scarves at regular intervals—every 10-15 pieces depending on production speed—to check for common defects:

- Banding or streaking resulting from misaligned print heads

- Color shifts due to ink depletion or temperature fluctuations

- Missing pixels indicating nozzle blockages

- Registration errors where color layers fail to align properly

- Ink bleeding into unintended areas, especially problematic with delicate fabrics

In 2025, manual inspections are increasingly augmented by machine vision systems utilizing high-resolution cameras and AI algorithms trained to detect subtle defects. These systems analyze up to 100% of production in real-time, comparing each scarf against a digital master template and flagging deviations exceeding established quality thresholds. When combined with automated sorting mechanisms, these technologies significantly reduce the number of defective products reaching final inspection.

Color management during production presents one of the most complex quality control challenges. Even with thorough pre-production calibration, environmental factors and material variations can cause color shifts. Advanced manufacturing facilities now employ inline spectrophotometers that measure color values at multiple points across each scarf, providing immediate feedback to the printer's color management system. This closed-loop correction process ensures consistent color application across individual production runs and between batches produced days or weeks apart.

For manufacturers serving international clients, maintaining color consistency across global facilities has traditionally posed significant challenges. Cloud-based color management platforms now synchronize color profiles and standards across geographically dispersed production locations, ensuring a design printed in Italy matches exactly with one produced in China. These systems also maintain comprehensive color history databases, enabling quick identification and resolution of emerging color drift patterns.

Post-Printing Quality Assurance Protocols

Print completion initiates the critical post-production quality assurance phase, where scarves undergo rigorous testing to verify market readiness. This comprehensive evaluation includes both mechanical testing of physical properties and detailed visual inspection under standardized conditions.

Color fastness testing forms the cornerstone of post-printing quality assurance for luxury scarves. The ISO 105 standard series provides the internationally recognized framework, with important updates in 2024-2025 refining testing methodologies. Key assessments include:

- ISO 105-C09: Color fastness to domestic and commercial laundering, critical for scarves requiring cleaning

- ISO 105-E04: Color fastness to perspiration, addressing dye stability against skin contact

- ISO 105-X12: Color fastness to rubbing/crocking, essential for accessories that contact other garments

- ISO 105-B04: Color fastness to light exposure, updated in 2024 to better simulate real-world conditions

The revised ISO 105-B04 standard deserves special attention, as it now specifies spectral irradiance requirements that more accurately replicate natural sunlight, providing improved predictions of long-term color stability. For luxury manufacturers, compliance with these standards ensures product quality and facilitates market access in regions with strict consumer protection regulations.

Physical durability testing evaluates how printed scarves withstand normal wear conditions. This includes abrasion resistance testing where samples undergo controlled rubbing against standardized surfaces to simulate friction from regular use. Flex testing assesses creasing resistance, while tensile strength measurements ensure the printing process hasn't compromised fabric integrity. For delicate fabrics like silk, trained evaluators conduct specialized hand feel assessments, rating texture before and after printing to ensure the digital process hasn't altered the material's luxurious characteristics.

Final inspection protocols represent the last quality control checkpoint before shipment approval. This comprehensive examination typically occurs under standardized lighting—D65 daylight simulators are preferred—to ensure consistent visual evaluation. Inspection criteria include:

- Overall print quality assessment, including resolution and detail reproduction

- Edge definition of printed elements, particularly critical for geometric patterns

- Color consistency across the entire scarf and between multiple scarves

- Absence of print defects like pinholes, smudges, or misregistration

- Proper finishing, including hem stitching quality and label attachment

- Conformance to size specifications with tolerances typically held to ±2mm for high-end products

Digital documentation systems have transformed final inspection processes. Each scarf receives a unique identifier linking to its complete quality control record. This digital trail includes high-resolution images of both sides, spectrophotometric color measurements, and mechanical testing results. Comprehensive documentation provides customer assurance while enabling manufacturers to analyze quality trends and identify continuous improvement opportunities.

Advanced Quality Control Technologies and Innovations

Digital textile printing quality control continues to evolve rapidly, driven by innovations that enhance precision, efficiency, and reliability. These technological advancements help scarf manufacturers differentiate themselves in competitive markets through superior quality offerings.

Artificial intelligence (AI) has become transformative in quality control applications. Machine learning algorithms now detect print defects with greater accuracy and consistency than human inspectors alone. These AI systems analyze thousands of printed samples to learn normal variation patterns and identify anomalies indicating potential quality issues. The most advanced 2025 AI applications uniquely correlate defect patterns with specific production parameters, enabling predictive maintenance that prevents quality issues before they occur.

One luxury scarf manufacturer reported a 42% defect rate reduction after implementing an AI-powered quality control system that continuously learns from production data. The system not only identifies existing defects but also generates alerts when process parameters drift toward ranges historically preceding quality issues, allowing adjustments before defective products are manufactured.

Internet of Things (IoT) integration provides unprecedented visibility into production processes. Networked sensors deliver real-time data on virtually every aspect of the printing environment. These smart systems monitor variables including ink temperature, humidity, print head performance, and curing oven efficiency, creating comprehensive digital twins of production processes. This digital representation enables quality control managers to identify subtle correlations between environmental factors and print quality, facilitating more precise process control.

For example, IoT data might reveal that color consistency varies with ambient humidity, prompting implementation of more sophisticated environmental controls. Vibration sensors on equipment can detect minute mechanical performance changes preceding component failure, allowing scheduled maintenance that prevents unplanned downtime and quality disruptions.

Nano-ink technology introduces new quality control considerations and capabilities. The latest nano-particle inks offer improved color saturation, durability, and environmental resistance compared to traditional formulations. However, these advanced materials require more precise process control, with particle dispersion, ink viscosity, and curing parameters all critical for optimal results.

Quality control for nano-ink applications includes specialized testing for particle aggregation that can cause defects and inconsistencies. Dynamic light scattering instruments measure particle size distribution in formulations, ensuring proper dispersion. Atomic force microscopy may examine printed sample surface topography, verifying that nano-ink layers form the intended structure for optimal color development and durability.

Blockchain technology is transforming quality control documentation and supply chain transparency. By creating immutable quality control test result records, blockchain provides customers with unprecedented visibility into product quality history. Each scarf can feature a unique digital identifier linking to its complete quality record from material testing through final inspection. This technology enhances manufacturer-buyer trust and facilitates efficient recalls if post-shipment quality issues emerge.

Looking ahead, emerging technologies like advanced digital twin technology will further revolutionize quality control by creating virtual replicas of production processes. These simulations will enable manufacturers to optimize quality control parameters virtually before implementing them physically, reducing waste and accelerating new scarf design time to market.

Quality Control Implementation and Management Systems

Effective quality control for direct-to-fabric printing on scarves requires more than advanced technology—it demands systematic quality management encompassing people, processes, and documentation. Manufacturers need comprehensive quality systems that standardize procedures, train personnel, and continuously improve through data analysis.

Quality management system design should follow established frameworks like ISO 9001, with specific procedures developed for each digital printing process stage. Documented procedures include detailed work instructions, quality checklists, and clear acceptance criteria for all control activities. For scarf production, special attention focuses on delicate fabric handling procedures with clear damage prevention protocols during printing, testing, and finishing operations.

Effective quality management systems establish clear responsibility and authority for control activities. This includes designating quality control inspectors independent of production personnel to ensure unbiased product assessment. Larger facilities may create dedicated quality assurance departments, while smaller operations assign these responsibilities to specially trained production staff with defined quality roles.

Training programs ensure consistent quality control implementation across all shifts and personnel. All staff involved in digital printing require regular training on quality standards, inspection techniques, and testing equipment operation. For manufacturers working with luxury materials, specialized modules address unique quality considerations including proper handling and material-specific testing protocols.

Training shouldn't be limited to technical staff. Management needs sufficient quality control knowledge to balance production efficiency with quality requirements. Frontline operators should learn to identify common quality issues and understand when to stop production for assistance. Well-trained workforces create "quality cultures" where every employee takes responsibility for maintaining standards.

Documentation and reporting systems form the backbone of effective quality management programs. These systems capture comprehensive data on all control activities:

- Material test results for incoming fabrics and inks

- Calibration records for printing and testing equipment

- In-process inspection findings and corrective actions

- Final inspection results, including pass/fail determinations

- Customer feedback and quality-related complaints

- Trend analysis reports identifying recurring issues

Modern quality management software integrates this data into intuitive dashboards providing real-time visibility of performance metrics. Systems generate automated alerts when indicators fall below established thresholds, enabling prompt corrective action. For manufacturers serving multiple customers, systems can also produce customized quality reports tailored to each client's specific requirements.

Continuous improvement processes ensure quality control systems evolve to address changing requirements and technologies. Regular management reviews of quality performance data identify improvement areas, with corrective and preventive actions implemented as needed. This structured approach includes root cause analysis of recurring defects, customer feedback analysis, and benchmarking against industry quality leaders.

The Plan-Do-Check-Act (PDCA) cycle provides an effective continuous improvement methodology with a systematic framework for testing control process changes. For example, a manufacturer might plan to implement a new AI-based inspection system, conduct a pilot production run (do), check results against quality metrics, and then act to standardize the new process or make adjustments based on lessons learned.

Supplier quality management represents another critical component of comprehensive quality control strategies. Scarf manufacturers must ensure material suppliers—including fabric producers and ink suppliers—maintain appropriate standards. This involves conducting supplier audits, establishing clear quality requirements in purchase specifications, and implementing incoming inspection procedures. Working closely with suppliers to improve their quality systems reduces variability in incoming materials and simplifies manufacturers' own control processes.

Conclusion: Building a Quality-Driven Competitive Advantage

In the rapidly evolving landscape of textile print innovation, quality control has become both a critical operational requirement and strategic differentiator. The technologies and methodologies outlined in this guide represent the current quality assurance state of the art, giving manufacturers the tools to meet luxury fashion market exacting standards.

Effective quality control spans the entire production process—from pre-production material testing through post-printing inspection. It requires combining advanced technology with standardized procedures and a committed workforce. The 2025 industry advancements, particularly in AI-powered inspection, IoT-enabled monitoring, and nano-ink technology, have elevated quality control from reactive testing to proactive management systems driving continuous improvement.

For fashion accessories retailers, boutiques, and brand owners, these quality control measures provide frameworks for evaluating potential suppliers and ensuring consistent product quality. When selecting digital scarf printing partners, look for manufacturers demonstrating not just ISO 105 standard compliance but also a commitment to continuous improvement through advanced quality management systems.

Superior quality control delivers competitive advantages beyond product consistency, including operational benefits like reduced waste, improved efficiency, and enhanced customer satisfaction. Manufacturers investing in robust quality control systems can capture premium pricing as quality-conscious buyers increasingly recognize the value of reliable, consistent print quality.

Looking forward, integrating emerging technologies like advanced digital twins, enhanced AI algorithms, and blockchain verification will further transform digital textile printing quality control. These innovations will enable greater precision, transparency, and efficiency while giving customers unprecedented visibility into each scarf's quality history.

In an industry where brand reputation depends on consistent excellence, implementing these advanced quality control measures isn't merely a competitive advantage—it's an essential business requirement for sustained success in the global luxury textile market.</think># Digital Textile Printing Quality Control for Luxury Scarves: Advanced Technical Standards and Best Practices

In the competitive landscape of luxury textile manufacturing, digital textile printing has emerged as a transformative technology, offering unprecedented design precision, customization capabilities, and production efficiency. As fashion houses and retailers demand consistent excellence across high-volume production runs, implementing robust quality control measures has become imperative for maintaining brand reputation and ensuring customer satisfaction.

This comprehensive technical guide outlines industry-leading quality control protocols specifically optimized for digital textile printing on scarf fabrics. Based on 2025 technological advancements and refined best practices, these methodologies span the entire production workflow—from pre-production material testing to post-printing inspection—ensuring every scarf meets the most stringent standards for color accuracy, durability, and aesthetic perfection.

The Evolving Quality Landscape in Digital Textile Printing

The global digital textile printing market continues its robust expansion at a 7.32% compound annual growth rate, projected to sustain this trajectory through 2030. This growth is fueled by evolving consumer preferences for personalized products and the fashion industry's accelerating shift toward sustainable production methods. Within this dynamic environment, scarf manufacturers face unique quality challenges due to the delicate nature of their products, often utilizing luxury materials like silk, cashmere, and fine wool that require specialized handling and printing techniques.

Critical quality parameters in digital scarf printing include color consistency across production runs, edge definition of printed patterns, color fastness to various environmental factors, and preservation of the fabric's inherent hand feel after printing. The technological advancements of 2025 have introduced new quality control variables, including AI-powered color management systems, IoT-enabled production monitoring, and nano-engineered inks that deliver enhanced vibrancy and durability.

Fashion accessories retailers and boutique buyers increasingly prioritize suppliers with rigorous quality control processes. A recent industry survey revealed that 87% of respondents identified "consistent print quality" as a primary factor when selecting scarf suppliers, while 76% cited "color fastness guarantees" as critical purchasing considerations. These findings underscore the strategic importance of implementing systematic quality control throughout the digital printing workflow.

Pre-Production Quality Control Foundations

Effective quality control begins long before the first print is executed. The pre-production phase establishes the essential foundation for consistent results by addressing both material characteristics and equipment calibration.

Material testing protocols ensure optimal compatibility between fabrics and digital printing processes. Each scarf material—whether silk, wool, cotton, or specialized synthetic blend