In the dynamic landscape of fashion accessories, digital textile printing has emerged as a transformative force, seamlessly merging creative expression with production efficiency. With years of specialized experience in textile innovation, I've witnessed firsthand how this technology has revolutionized scarf manufacturing—unlocking unprecedented design possibilities, accelerating production cycles, and advancing sustainability initiatives. This authoritative guide delves into the technical complexities of digital textile printing for scarves, equipping fashion brands, manufacturers, and industry professionals with actionable insights to navigate today's competitive market landscape.

Understanding Digital Textile Printing Technology for Scarves

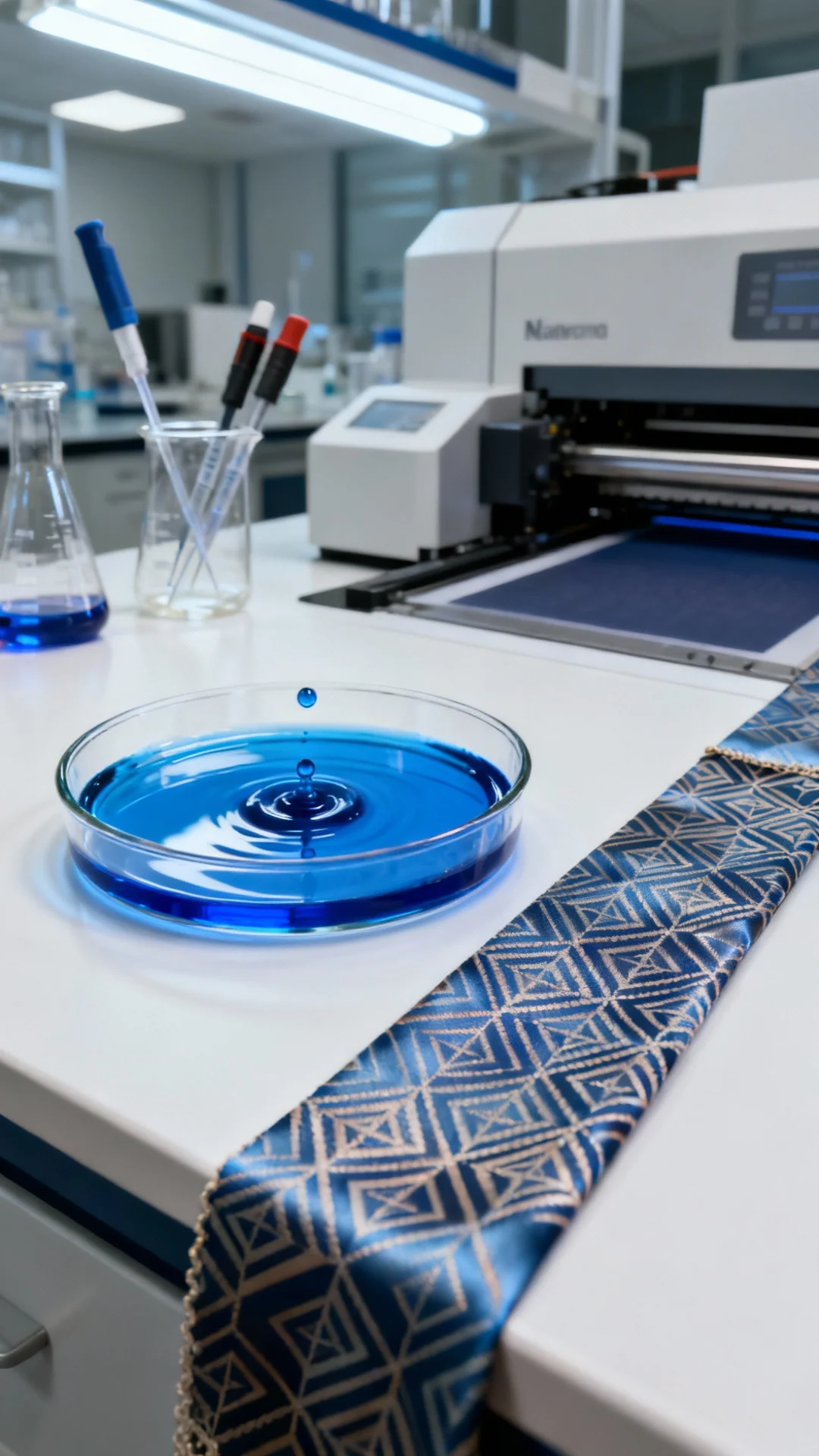

Digital textile printing represents a paradigm shift from traditional methods such as screen printing, employing a direct-to-fabric approach that eliminates many inherent limitations of conventional techniques. At its core, this technology utilizes sophisticated inkjet printers to transfer digital designs directly onto textile substrates, resulting in vibrant, high-resolution patterns with exceptional precision and detail.

The significance of this technology in scarf production has grown exponentially, with industry analysts projecting the global digital textile printing market to reach $19.44 billion by 2025. This growth trajectory is particularly pronounced in the luxury accessories segment, where scarf manufacturers are leveraging digital capabilities to meet escalating demands for customization, rapid turnaround, and design complexity.

Core Components of Digital Scarf Printing Systems

Modern digital textile printing systems for scarves integrate several specialized components working in harmony to deliver superior results:

Print Heads and Ink Delivery Systems have undergone remarkable evolution. Advanced piezoelectric print heads now deposit ink droplets as small as 4 picoliters, enabling the creation of intricate designs with exceptional detail—an essential capability for luxury scarf applications where subtlety and complexity differentiate premium products. Cutting-edge production systems like the EFI Reggiani HYPER now offer speeds that render digital printing viable for both small-batch customization and larger production runs, fundamentally altering traditional manufacturing economics.

Pre-treatment Units play a critical role in preparing delicate scarf fabrics such as silk and cashmere. These precision systems apply specialized chemical solutions that optimize ink absorption and fixation, ensuring superior colorfastness and durability—qualities of particular importance for accessories subjected to frequent handling and wear.

Drying and Curing Modules utilize advanced heating technologies to set inks without compromising sensitive fibers. For the natural fabrics commonly favored in luxury scarf production, precise temperature control prevents shrinkage or fiber distortion while ensuring complete ink polymerization and optimal color development.

Material Considerations for Scarf Printing

Different scarf materials present unique challenges and requirements in the digital printing process, necessitating specialized approaches:

Silk, the preeminent choice for luxury scarves, demands specialized handling due to its delicate nature and protein structure. Digital printing on silk typically employs acid-based or reactive inks that form molecular bonds with fiber proteins, resulting in exceptional color vibrancy and maintaining the fabric's characteristic soft hand feel. Recent advancements in nano-ink formulations have effectively resolved traditional challenges with bleed-through and color consistency on silk substrates.

Wool and Cashmere scarves benefit significantly from digital printing's ability to achieve precise color placement without the harsh chemical treatments associated with traditional dyeing processes. Specialized pre-treatment protocols gently open fiber scales to accept ink particles, ensuring excellent color retention even after repeated washing and wear.

Synthetic Blends offer distinct advantages in print durability and colorfastness. Polyester-cotton blends commonly used in fashion scarves demonstrate excellent compatibility with disperse inks, providing an optimal balance between comfort and performance characteristics.

A thorough understanding of these material-specific requirements constitutes the foundation for achieving professional results in digital scarf printing, as each fabric type interacts uniquely with inks and printing processes.

Advanced Technologies Reshaping Modern Scarf Printing

The digital textile printing landscape for scarves is continuously evolving, driven by cutting-edge technologies that enhance both quality parameters and production capabilities. These innovations empower fashion brands to differentiate their scarf offerings through technical excellence and design innovation.

Nano-Ink Technology: Precision at the Molecular Level

Nano-ink technology represents one of the most significant advancements in digital textile printing for scarves. By engineering ink particles at the nanoscale (typically 1-100 nanometers), manufacturers have achieved remarkable breakthroughs in color intensity, wash fastness, and fabric penetration—factors critical to luxury scarf performance.

These advanced inks offer several specific benefits for scarf production:

Enhanced Color Gamut enables more nuanced color transitions and gradient effects, essential for reproducing artistic designs and complex patterns often featured in high-end scarves. The reduced particle size increases light reflection properties, resulting in more vibrant colors that maintain their brilliance over extended periods of wear.

Improved Adhesion to diverse fiber types addresses a longstanding challenge in scarf printing. Nano-particles form stronger molecular bonds with both natural and synthetic fibers, significantly reducing issues with rubbing fastness that have traditionally plagued conventional inks—particularly important for accessories subject to frequent contact and handling.

Reduced Environmental Impact through lower volatile organic compound (VOC) emissions aligns perfectly with the growing sustainability demands of luxury fashion consumers. Nano-ink formulations typically require less energy for curing and produce fewer hazardous byproducts, supporting both environmental and corporate social responsibility initiatives.

Recent studies on ink rheology have optimized nano-ink flow characteristics specifically for scarf printing applications, ensuring consistent droplet formation and precise placement even on delicate, loosely woven fabrics often utilized in luxury scarf production.

High-Speed Printing Machines: Balancing Speed and Quality

The latest generation of high-speed digital textile printers has transformed production possibilities for scarf manufacturers. These systems deliver impressive performance metrics that were unimaginable just a few years ago, fundamentally changing the economics of digital scarf production.

Key performance indicators for evaluating these systems include:

Production Speed, measured in square meters per hour, has reached levels that make digital printing competitive with traditional methods for medium to large production runs. Leading-edge machines now offer production capabilities that significantly reduce per-unit costs for scarf manufacturers while maintaining premium quality standards.

Color Consistency across production runs is ensured through advanced closed-loop color management systems that continuously monitor and adjust ink deposition in real time. This capability guarantees batch-to-batch uniformity—a critical factor for fashion brands maintaining consistent product lines and brand identity.

Energy Efficiency has improved dramatically, with modern printers consuming up to 30% less power than previous generations. This reduction not only lowers operational costs but also strongly supports sustainability initiatives increasingly important to luxury consumers and brand values.

For scarf manufacturers, these technological advancements translate to greater flexibility in production planning, enabling both rapid response to emerging trend changes and efficient production of core designs. The ability to quickly switch between designs without the setup costs associated with screen printing has proven particularly valuable in the fast-evolving accessories market.

Direct-to-Fabric Printing: Streamlining Production Workflows

Direct-to-fabric (DTF) printing technology has revolutionized scarf production by eliminating several intermediate steps traditionally required in textile decoration processes. This innovative approach involves printing designs directly onto pretreated scarf fabrics, resulting in a highly efficient workflow with numerous advantages for scarf production.

The optimized DTF workflow for scarves typically follows these streamlined steps:

- Design Preparation using specialized software that accounts for fabric characteristics and precise print dimensions

- Fabric Pretreatment applying substrate-specific solutions to enhance ink adhesion and color development

- Digital Printing with precision alignment for scarf dimensions and repeat patterns

- Ink Fixation through controlled heat application that sets colors without damaging delicate fibers

- Finishing Processes including washing, drying, and rigorous quality inspection

This streamlined approach offers significant benefits for scarf production, reducing water consumption by up to 95% compared to traditional printing methods while enabling faster turnaround times and enhanced design flexibility. For luxury scarf producers, DTF technology facilitates the creation of limited-edition designs with the same production efficiency as core collections.

Practical Implementation Guide for Scarf Manufacturers

Successfully implementing digital textile printing for scarf production requires meticulous planning beyond mere equipment acquisition. Based on industry best practices and practical experience, this guide outlines key considerations for fashion brands and manufacturers adopting this transformative technology.

Equipment Selection and Configuration

Choosing the right digital printing system for scarf production involves evaluating several critical factors beyond initial cost considerations:

Printer Type selection should be guided by primary scarf materials and projected production volumes. Piezoelectric inkjet printers generally offer the optimal combination of quality and versatility for scarf applications, with configurations available for both natural and synthetic fibers.

Ink Compatibility represents an essential consideration, as different ink types (reactive, acid, disperse, pigment) perform distinctly on various scarf materials. Silk scarves typically require acid or reactive inks, while polyester blends demonstrate superior results with disperse inks.

Ancillary Equipment including pretreatment systems, precision dryers, and finishing equipment should be sourced as an integrated system to ensure compatibility and optimal performance. Many manufacturers offer specialized turnkey solutions specifically configured for scarf production requirements.

Software Integration with existing design and production management systems is often overlooked but critical for maximizing operational efficiency. Color management software, design preparation tools, and production planning systems should work seamlessly with printing equipment to ensure a cohesive workflow.

For boutique operations focusing on high-end silk scarves, appropriately configured entry-level systems can deliver excellent results with lower initial investment. Medium to large manufacturers may benefit from industrial-grade equipment with higher throughput capabilities and advanced automation features tailored to their production scale.

Workflow Optimization for Scarf Production

Optimizing the digital printing workflow specifically for scarf production involves addressing the unique characteristics of these accessories:

Design File Preparation demands careful attention to scarf dimensions, repeat patterns, and color profiles. Industry best practices recommend working with vector graphics for scalability and employing color separation techniques that account for fabric absorption characteristics.

Color Management systems should be calibrated regularly using actual scarf fabric swatches rather than generic substrates, ensuring accurate color reproduction on the specific materials used in production.

Production Scheduling benefits significantly from grouping similar scarf designs and color palettes to minimize machine setup changes. Digital printing's quick changeover capabilities make small-batch production economically viable, supporting customization strategies and limited-edition offerings.

Quality Control Checkpoints should be strategically integrated throughout the production process, with specific attention to color accuracy, pattern alignment, and ink fixation—particularly important for scarves where visual perfection constitutes a key selling point.

Implementing these workflow optimizations typically results in a 20-30% increase in production efficiency, according to industry benchmarks, while simultaneously improving quality consistency and reducing material waste.

Troubleshooting Common Technical Challenges

Even with meticulous implementation, digital scarf printing can present technical challenges requiring specific solutions:

Color Bleeding on natural fibers like silk can often be resolved through adjusted pretreatment formulations or modified curing temperatures. Conducting thorough testing with different pretreatment concentrations on specific scarf fabrics is strongly recommended.

Ink Adhesion Issues may require substrate-specific pre-treatment modifications or adjustments to ink viscosity parameters. Advanced nano-ink formulations have demonstrated particular effectiveness in improving adhesion on difficult-to-print scarf materials.

Pattern Distortion can result from fabric stretching during printing. Implementing precision tension control systems and selecting appropriate gripper configurations for different scarf materials helps maintain pattern integrity throughout the production process.

Color Inconsistency between production runs often stems from environmental factors. Maintaining consistent temperature (ideally 20-24°C) and humidity (55-65% relative humidity) in the printing facility significantly enhances color reproducibility.

Developing a comprehensive troubleshooting guide specific to the scarf materials and designs being produced minimizes production disruptions and maintains stringent quality standards.

Comparative Analysis: Digital vs. Traditional Scarf Printing

Understanding the relative advantages and limitations of digital versus traditional printing methods empowers scarf manufacturers to make strategic production decisions aligned with their business objectives and market positioning.

Quality and Design Capabilities

Digital printing offers several quality advantages specifically beneficial for scarf production:

Color Range and Gradation capabilities far exceed traditional methods, with modern digital systems reproducing over 90% of the Pantone color gamut. This enables the subtle color transitions and complex gradients often featured in high-end scarf designs, providing a distinct competitive advantage.

Design Resolution of 1200-1800 dpi achievable with advanced digital systems captures intricate details that would be lost in screen printing processes. For scarves featuring fine art reproductions or detailed patterns, this level of resolution often serves as a key market differentiator.

Design Placement Precision ensures accurate alignment of patterns across scarf dimensions, with advanced systems offering registration accuracy within 0.1mm. This precision is particularly valuable for symmetrical designs and intricate border details that define premium scarf products.

Traditional screen printing, while capable of producing excellent results for certain applications, faces inherent limitations in handling complex color gradients and fine details. Each color requires a separate screen, making designs with multiple colors or subtle transitions economically challenging and technically difficult to execute consistently.

Production Efficiency and Cost Considerations

The economic comparison between digital and traditional methods for scarf production reveals distinct trade-offs:

Setup Costs for digital printing are significantly lower, as there are no screens to create, store, or maintain. This fundamental advantage makes small production runs and custom designs economically viable—particularly valuable for scarf manufacturers serving boutique clients or creating limited-edition collections.

Production Speed varies by method and volume characteristics. Traditional screen printing maintains a comparative advantage for very large runs of simple designs, while digital printing becomes more efficient for shorter runs or designs with multiple colors. Recent advancements in high-speed digital printers have narrowed this gap considerably, with technology continuing to evolve rapidly.

Material Waste is substantially reduced with digital printing, which typically generates 80-90% less textile waste than traditional methods. This reduction not only minimizes environmental impact but also lowers material costs for high-end scarf fabrics, where waste represents a significant financial consideration.

For many scarf manufacturers, the optimal production approach involves a strategic hybrid strategy: utilizing digital printing for custom orders, limited editions, and complex designs while employing traditional methods for high-volume basic designs. This integrated approach leverages the strengths of each technology while mitigating their respective limitations.

Sustainability and Environmental Impact

Environmental considerations have become increasingly important in luxury scarf production, with digital printing offering significant sustainability advantages:

Water Consumption is dramatically lower in digital processes, which use approximately 95% less water than traditional screen printing. For a typical scarf production run, this translates to savings of thousands of liters of water—a substantial environmental benefit and increasingly important consumer preference factor.

Chemical Usage is significantly reduced through targeted ink application and advanced pretreatment processes. Digital printing eliminates the need for many hazardous chemicals used in traditional textile printing, supporting safer working environments and reduced environmental impact across the supply chain.

Energy Efficiency has improved substantially with modern digital printers consuming less power per square meter of printed fabric. When combined with efficient curing systems, this results in a significantly lower carbon footprint compared to traditional methods.

Waste Reduction extends beyond materials to include ink waste, as digital systems precisely deposit only the required amount of ink. This contrasts sharply with traditional methods where excess ink often becomes hazardous waste requiring specialized disposal.

These sustainability benefits have evolved from purely environmental considerations to become important selling points for luxury scarf brands, resonating strongly with environmentally conscious consumers willing to pay premium prices for products aligned with their values.

Industry Trends and Future Developments (2025 and Beyond)

The digital textile printing landscape for scarves continues to evolve at a rapid pace, driven by technological innovations and changing market demands. Understanding these emerging trends helps manufacturers maintain competitive advantage in the luxury accessories market.

Sustainable Innovations in Ink Technology

The development of eco-friendly inks has accelerated dramatically, with several promising innovations on the horizon for 2025 and beyond:

Bio-based Inks formulated from renewable resources are gaining significant traction, with manufacturers developing sophisticated formulations using plant-derived pigments and binders. These innovative inks reduce reliance on petroleum-based products while maintaining exceptional colorfastness and vibrancy characteristics.

Waterless Printing Technologies currently in advanced development stages could eliminate water usage entirely in certain scarf printing applications. These systems utilize UV-curable inks that polymerize when exposed to specific light wavelengths, offering transformative environmental benefits.

Recyclable Ink Systems allowing for fabric recycling at end-of-life are being actively explored by several research institutions. These pioneering inks are designed to break down during textile recycling processes, enabling closed-loop material cycles for truly sustainable scarf production.

For luxury scarf brands, these sustainable innovations represent more than just environmental responsibility—they offer compelling opportunities for product differentiation and alignment with the evolving values of discerning consumers in the premium accessories market.

Integration of AI and Digital Design Tools

Artificial intelligence is transforming the digital textile printing workflow for scarves, offering new possibilities for design creation and production optimization:

AI-Powered Design Assistance tools can generate pattern variations, color palettes, and design elements based on comprehensive trend analysis and brand aesthetic parameters. These intelligent systems help designers explore creative possibilities while significantly reducing development timeframes.

Predictive Quality Control leverages machine learning algorithms to identify potential printing issues before production begins. By analyzing design files and material characteristics, these advanced systems can predict and prevent common defects in digital scarf printing, ensuring consistent quality standards.

Production Optimization AI continuously analyzes printing parameters and makes real-time adjustments to maintain optimal quality and efficiency. This adaptive technology ensures consistent results even as environmental conditions or material characteristics vary slightly during production runs.

For scarf manufacturers, these digital tools streamline the transition from design concept to finished product, reducing time-to-market while preserving the creative integrity that defines luxury accessories in competitive marketplaces.

On-Demand Production and Customization Trends

Changing consumer expectations are driving significant shifts in scarf production models, with on-demand production and customization emerging as defining industry trends:

Mass Customization capabilities enabled by digital printing allow scarf brands to offer personalized designs at scale. Advanced systems can incorporate individual names, initials, or custom elements into designs without disrupting production efficiency or compromising quality standards.

Localized Production Networks are becoming increasingly viable as digital printing reduces setup costs and production lead times. This distributed model reduces shipping distances and associated carbon emissions while enabling faster response to regional trend variations and consumer preferences.

Seasonless Production is gradually replacing traditional seasonal manufacturing cycles, with brands utilizing digital printing to produce smaller batches more frequently. This agile approach reduces inventory risks while allowing scarf designs to quickly adapt to emerging fashion trends and consumer demands.

These transformative trends align perfectly with the inherent characteristics of digital textile printing, which excels at short runs, quick changeovers, and design flexibility. For forward-thinking scarf manufacturers, embracing these models represents a significant competitive advantage in an increasingly personalized and sustainability-focused market landscape.

Implementation Strategy and Best Practices

Successfully adopting digital textile printing for scarf production requires more than just new equipment—it demands a comprehensive strategic approach addressing technical, operational, and market considerations. Based on industry best practices and practical experience, this final section outlines a structured implementation strategy to maximize return on investment and ensure long-term success.

Equipment Investment and ROI Planning

Making informed equipment decisions involves careful analysis of both technical capabilities and financial returns:

Needs Assessment should thoroughly evaluate current and projected production volumes, typical design complexity, material types, and quality requirements. This assessment forms the foundation for equipment specifications and budget allocation, ensuring alignment with business objectives.

Total Cost of Ownership calculations must extend beyond initial purchase price to include consumables, maintenance, energy usage, and operator training. For scarf manufacturers, ink costs represent a significant ongoing expense that varies substantially by printer type and ink technology, warranting careful analysis during the decision-making process.

ROI Timeline varies based on production volume and business