In today's rapidly evolving fashion landscape, selecting the optimal printing technology for scarf production has become a critical strategic decision with far-reaching implications for brand success. With extensive experience in textile manufacturing and fashion accessory development, I've witnessed firsthand how printing technology choices impact product quality, operational efficiency, and market responsiveness. This analysis provides a detailed comparison of digital and traditional scarf printing methods, examining their technical capabilities, economic considerations, and creative potential to help fashion businesses navigate production decisions for 2025 and beyond.

Technical Foundations: Understanding the Printing Processes

Traditional Scarf Printing Techniques

Traditional printing methodologies—encompassing screen printing, block printing, and roller printing—have served as the backbone of textile production for generations. These established techniques rely on physical stencils or engraved plates to transfer ink onto fabric substrates through mechanical pressure application. Screen printing, the predominant traditional method for scarf production, necessitates separate screens for each color component in a design, with each hue requiring a distinct production pass.

The technical constraints of traditional production become evident when examining workflow requirements. Fabricating physical screens demands substantial setup time and material investment, rendering traditional printing economically feasible primarily for large-volume production runs. Nevertheless, traditional methods excel in delivering bold, opaque color coverage and specialized textural effects that remain challenging to replicate with digital alternatives.

Modern Digital Scarf Printing Technology

Digital scarf printing represents a transformative advancement in textile decoration, utilizing sophisticated inkjet technology to apply colorants directly to fabric surfaces without the need for physical screens. The process initiates with a digital design file that undergoes optimization through specialized RIP (Raster Image Processor) software, which prepares the image for textile application and precisely controls ink deposition.

Contemporary digital textile printers achieve resolutions up to 1200 dpi, with industrial models capable of production speeds reaching 100 meters per hour. This technology now accommodates an extensive range of fabric types, from delicate silks to durable cottons, utilizing specialized ink formulations engineered for different fiber compositions. The latest generation of digital printers emerging in 2025 incorporates precision droplet control systems and advanced multi-pass printing heads, delivering unprecedented color accuracy and detail reproduction capabilities.

Quality and Aesthetic Capabilities Compared

Color Performance and Visual Impact

When evaluating print quality parameters, digital and traditional methods each demonstrate distinct strengths. Digital printing technology excels at rendering intricate details, smooth gradients, and photographic imagery with exceptional clarity and precision. Capable of reproducing up to 16 million colors, digital systems offer a color gamut that surpasses most traditional printing methods.

Conversely, traditional screen printing typically delivers superior color saturation for solid color block applications and achieves deeper ink penetration, resulting in enhanced colorfastness for specific use cases. The tactile characteristics differ significantly between methods—traditionally printed scarves often feature more pronounced ink laydown, creating subtle textural variations that many luxury brands and discerning consumers find desirable.

Industry-standard testing protocols indicate that digital printing maintains approximately 85-90% of original color intensity after 20 wash cycles, compared to 90-95% retention for professionally executed screen printing. However, recent innovations in pigment-based digital inks have substantially narrowed this performance gap, with premium formulations now approaching traditional methods' colorfastness properties.

Texture and Tactile Qualities

The tactile dimension of printed scarves represents a crucial quality parameter that significantly influences consumer perception and brand positioning. Traditional printing methods typically produce more pronounced surface texture due to thicker ink deposits, creating distinctive hand-feel characteristics that certain luxury market segments specifically seek.

Digital printing generally results in thinner, more uniform ink distribution that preserves the original fabric's drape and handle—an advantage for lightweight scarves and designs where fabric flow is aesthetically important. This distinction has led to the development of specialized digital printing techniques that intentionally create textural effects, bridging the tactile gap between the two technologies.

Production Dynamics: Flexibility, Speed, and Scalability

Digital Printing: Agility in Modern Fashion Production

Digital printing technology has revolutionized production paradigms for fashion brands by fundamentally altering economic equations around batch size and production timing. With minimal setup requirements, digital systems transition from design approval to production in hours rather than the days or weeks required by traditional methods. This operational agility delivers several strategic advantages:

- Small-batch production: Enables economically viable runs of just 1-5 scarves, perfect for limited editions and exclusive collections

- Rapid prototyping: Facilitates quick design iteration and sampling without substantial financial investment

- Design variability: Allows easy incorporation of unique elements into individual pieces within a production run

- Seasonal adaptation: Provides the ability to respond swiftly to emerging trends with controlled inventory risk

These capabilities have proven particularly valuable in the fast-paced fashion industry, where market responsiveness and trend adaptation directly impact profitability and brand relevance.

Traditional Printing: Efficiency in High-Volume Production

Traditional printing methods require more substantial production commitments, typically necessitating minimum runs of 50-100 units to justify setup costs. This characteristic makes traditional techniques better suited for core collection pieces with stable demand rather than trend-driven or niche market applications.

Lead times for traditional printing generally range from 2-4 weeks, compared to 2-5 days for digital production. However, for very large production volumes exceeding several thousand units, traditional methods often deliver superior production efficiency and per-unit cost advantages that can offset their longer lead times.

Environmental Impact and Sustainability Considerations

Water and Resource Consumption

Sustainability has emerged as a decisive factor in printing technology selection, with both methods presenting distinct environmental profiles. Digital printing demonstrates clear advantages in several key sustainability metrics:

- Water consumption: Uses up to 95% less water than traditional screen printing, which requires extensive water usage for screen preparation, color mixing, and cleanup processes

- Ink utilization: Precise ink deposition reduces waste by 30-50% compared to traditional methods, which typically generate substantial ink waste during setup and color changes

- Chemical reduction: Eliminates many toxic chemicals used in screen preparation, emulsion processing, and traditional dye fixation

- Energy efficiency: Modern digital printers incorporate advanced energy-saving features that reduce carbon footprint by 20-35% compared to conventional printing equipment

Environmental Certification and Compliance

A 2025 environmental impact analysis from a leading textile research institute confirmed that digital printing produces approximately 45% less carbon emissions per scarf than traditional screen printing for production runs under 500 units. For larger production volumes, this gap narrows but rarely disappears entirely.

Many digital printing operations now utilize water-based, eco-friendly inks that further minimize environmental impact while meeting stringent certification standards such as OEKO-TEX and GOTS—credentials increasingly demanded by environmentally conscious consumers and retail partners.

Economic Analysis: Cost Structures and Investment Considerations

Per-Unit Cost Dynamics

The economic equation between digital and traditional printing depends fundamentally on production volume, with each method offering distinct cost advantages in different scenarios. For small production runs (under 100 units), digital printing typically delivers lower total costs despite higher per-unit expenses, as it eliminates substantial setup costs associated with traditional methods.

Industry data from 2025 indicates these approximate cost ranges for silk scarf production:

- Digital printing: $8.50-$15.00 per unit for runs of 1-50 scarves

- Traditional screen printing: $12.00-$25.00 per unit for runs of 50-100 scarves, decreasing to $5.00-$8.00 per unit for runs exceeding 500 scarves

These figures include all production costs except design development and fabric sourcing. The cost crossover point—where traditional printing becomes more economical—typically occurs between 150-200 units for standard scarf designs utilizing 3-5 colors.

Total Cost of Ownership Analysis

Beyond direct production costs, fashion brands must consider various indirect expenses that influence the total cost of ownership:

- Inventory carrying costs: Digital's suitability for small-batch production reduces inventory investment and obsolescence risk

- Design iteration costs: Traditional methods require new screens for design modifications, adding $150-300 per design change

- Minimum order quantities: Traditional printers often enforce minimum orders of 50-100 units per design/colorway

- Storage requirements: Physical screens demand dedicated storage space and maintenance, creating long-term cost liabilities

For fashion brands operating in dynamic markets or offering extensive customization options, these indirect costs frequently make digital printing the more economical choice despite higher per-unit production expenses for small batches.

Material-Specific Applications and Techniques

Silk Scarf Printing: Technical Considerations

Silk presents unique challenges and opportunities for both printing methodologies. Digital printing on silk has advanced considerably, utilizing specialized aqueous dye inks that penetrate the fiber structure while preserving silk's natural drape and luster. This process enables exceptional color graduation and detail rendering that complement silk's luxurious aesthetic qualities.

Traditional silk printing, particularly hand-screened methods, retains value for creating depth through layered ink application and certain textural effects that remain difficult to replicate digitally. However, the water and chemical requirements of traditional silk printing create increasing environmental challenges that many brands find difficult to justify in today's sustainability-focused market.

Industry best practices for digital silk printing emphasize proper pre-treatment and post-print curing to ensure optimal colorfastness and handle. When executed correctly, digitally printed silk scarves achieve washfastness ratings of 4-5 on the AATCC scale, approaching the performance of traditional methods.

Cotton and Alternative Fiber Scarves

Cotton scarves benefit significantly from digital printing's ability to handle the fiber's absorbent nature without compromising detail reproduction. The technology performs well with both natural and pre-dyed cotton substrates, delivering consistent results across production runs.

For blended fabrics and synthetic fibers, digital printing offers superior formulation flexibility through specialized ink chemistry. Polyester-cotton blends—increasingly popular for affordable fashion scarves—print particularly well with digital disperse inks that bond effectively to both fiber types, creating durable, vibrant designs.

Traditional printing methods maintain advantages for heavy cotton scarves where ink opacity and durability are primary concerns, such as outdoor or utility-oriented designs where performance considerations outweigh aesthetic nuances.

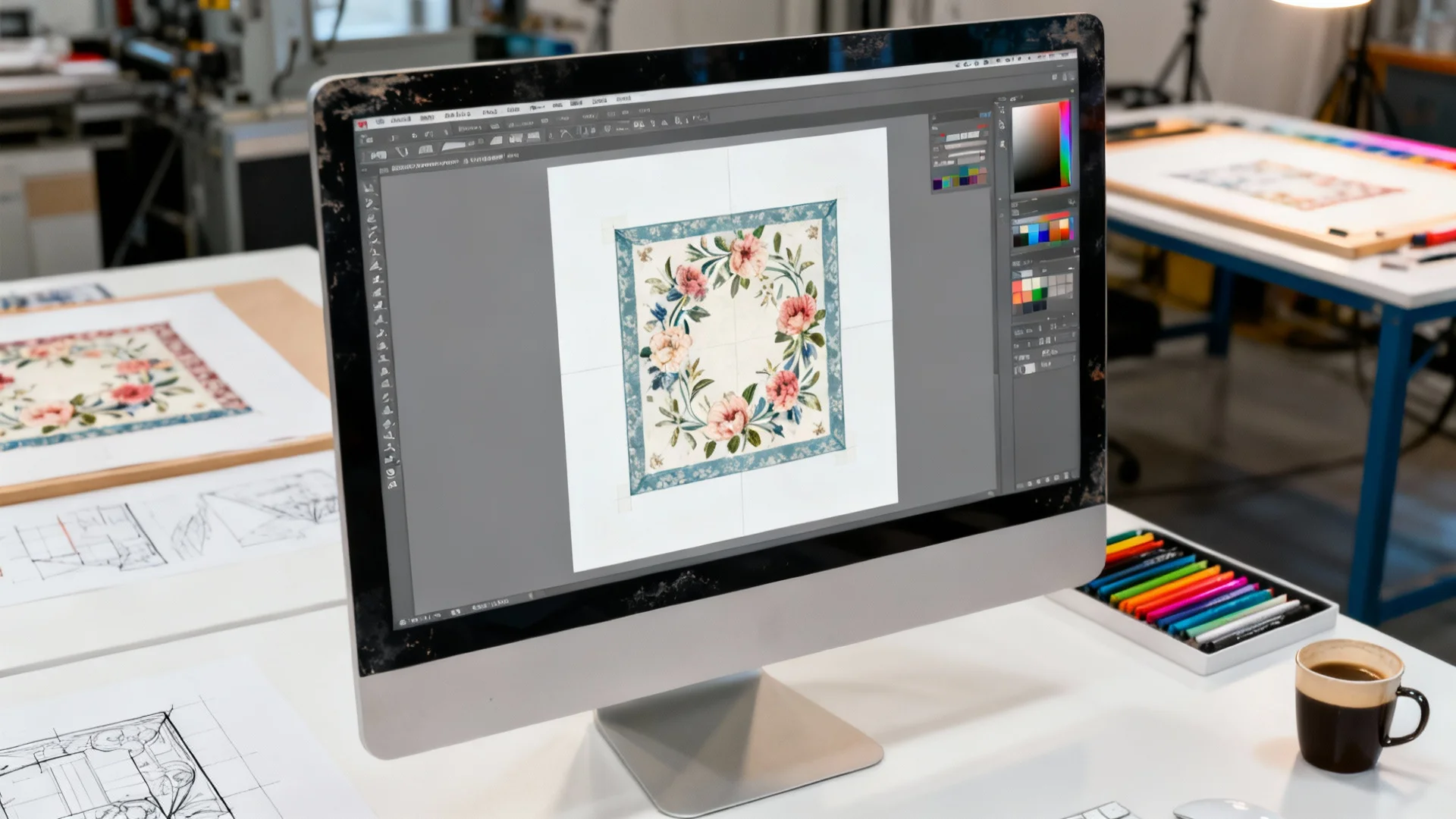

Scarf Digital Design Technology: Software and Workflow Integration

Modern scarf digital design technology has evolved into sophisticated ecosystems that streamline the transition from creative concept to physical product. Leading design software platforms now offer specialized tools for scarf production, including repeat pattern generation, colorway management, and fabric simulation capabilities that provide accurate previews of final printed results.

These digital design workflows integrate seamlessly with production systems, enabling direct file transfer to printing equipment and minimizing reproduction errors. Advanced systems incorporate color management protocols that ensure consistency across different printing technologies and material substrates—a critical capability for brands maintaining cohesive visual identities across product lines.

Custom Printed Scarf Techniques: Personalization and Brand Differentiation

Custom printed scarf techniques have emerged as powerful tools for brand differentiation and consumer engagement. Digital printing technology has been instrumental in expanding customization possibilities, enabling:

- Variable data printing that incorporates unique elements into individual pieces within a production run

- Photo-realistic reproduction of custom imagery

- On-demand personalization for corporate gifts and special occasions

- Limited edition runs with individualized elements

These capabilities have created new business models for fashion brands, including made-to-order scarf programs and personalized luxury offerings that command premium price points while maintaining efficient production processes.

Emerging Trends and Future Developments

AI Integration in Digital Printing Workflows

Artificial intelligence represents one of the most significant developments in digital printing for 2025 and beyond. AI-powered design tools now enable capabilities that were previously impractical or impossible:

- Automated pattern creation and intelligent modification

- Color palette optimization for specific fabrics and printing technologies

- Design adaptation for different scarf dimensions and shapes

- Predictive quality control and defect detection systems

These advancements reduce design development time by 30-40% while expanding creative possibilities, enabling fashion brands to generate endless variations of base designs and create hyper-customized offerings at scale.

Technological Advancements Reshaping the Landscape

Printer manufacturers continue to push the boundaries of digital textile printing technology. The 2025 product lineup includes systems featuring:

- Increased production speeds reaching up to 150 meters/hour

- Enhanced energy efficiency with 25% reduction in power consumption

- Advanced connectivity with Industry 4.0 production systems

- Multi-material printing capabilities that expand application possibilities

These technological improvements are progressively enhancing digital printing's competitiveness against traditional methods, particularly for mid-volume production runs that previously represented traditional printing's stronghold.

Strategic Recommendations for Fashion Brands

Based on current industry data and technological capabilities, fashion brands should consider the following guidelines when selecting printing methods:

Opt for digital printing when:

- Designs feature complex details, gradients, or photographic elements

- Production runs consist of fewer than 200 units

- Fast turnaround and market responsiveness are priorities

- Sustainability metrics are central to brand identity

- Customization or personalization options are offered

Consider traditional printing for:

- High-volume basic designs with limited color complexity

- Applications requiring maximum color vibrancy for solid color blocks

- Brand positioning that emphasizes traditional craftsmanship values

- Production runs consistently exceeding 500 units per design

Many successful fashion brands have adopted hybrid strategies, leveraging digital printing for limited editions, prototypes, and trend-driven pieces while maintaining traditional production for core, high-volume designs. This balanced approach enables brands to optimize both creative expression and production economics.

Conclusion: Strategic Technology Integration for Modern Fashion Brands

The decision between digital and traditional scarf printing ultimately hinges on a brand's specific circumstances, strategic priorities, and market positioning. Digital technology has made substantial advancements in quality, sustainability, and cost-effectiveness, yet traditional methods retain distinct advantages for certain applications and production scales.

As we progress further into 2025, the most successful fashion brands will likely employ strategic technology integration, matching each design and production requirement with the method best suited to deliver optimal results. Understanding the technical capabilities, economic factors, and sustainability implications of each approach enables brands to balance creative vision with commercial practicality effectively.

The future of scarf printing lies not in the wholesale replacement of one method with another, but in the intelligent integration of technologies that expand creative possibilities while addressing evolving consumer demands and global marketplace expectations. By carefully evaluating each production scenario against both printing methodologies' strengths and limitations, fashion brands can position themselves for success in an increasingly competitive and rapidly changing industry landscape.