In an era where environmental consciousness shapes both consumer preferences and industrial innovation, digital printing technology stands at the forefront of transforming scarf manufacturing. With extensive experience bridging textile production and sustainability implementation, I've witnessed digital printing evolve from specialized technology to mainstream solution—enabling brands to reduce environmental impact without compromising artistic expression or quality craftsmanship.

The global digital textile printing market is projected to reach $19.44 billion by 2025, driven largely by demand for sustainable production methods in fashion accessories. This growth represents a fundamental industry shift: sustainability has transitioned from marketing narrative to core competitive advantage. For boutique owners, specialty retailers, and fashion brands evaluating manufacturing partners, understanding these technological advancements is essential for aligning ethical values with commercial objectives.

The Environmental Imperative in Scarf Manufacturing

Traditional scarf production has long posed significant environmental challenges, from excessive resource consumption to chemical pollution. Conventional screen printing requires separate screens for each color, generating substantial waste while consuming vast amounts of water—often exceeding 200 liters per kilogram of fabric. The scarf manufacturing segment, particularly with luxury materials like silk and wool, has faced increasing scrutiny for its environmental footprint, with dyeing and printing processes contributing disproportionately to the fashion industry's water pollution crisis.

The statistics are compelling: the fashion industry consumes approximately 35 trillion liters of water annually, with textile printing accounting for a significant portion. Producing a single conventional silk scarf can require up to 1,500 liters of water across all production stages—equivalent to the average person's water consumption over 2.5 years.

Beyond water challenges, conventional printing generates substantial textile waste. Factories typically require large minimum order quantities to justify production setup costs, leading to overproduction and unsold inventory frequently destined for landfills. Chemicals in traditional inks and fixatives compound environmental harm, with many substances persisting in ecosystems while creating health risks for factory workers.

Consumers have taken notice of these environmental impacts. A 2025 consumer insights report revealed that 73% of luxury accessories buyers consider sustainability when making purchasing decisions, with 68% willing to pay premium prices for products with verified eco-friendly credentials. For businesses targeting discerning customers—especially in boutique and specialty retail—sustainable manufacturing has evolved from corporate social responsibility initiative to business necessity.

Digital Printing Technology: A Sustainable Alternative

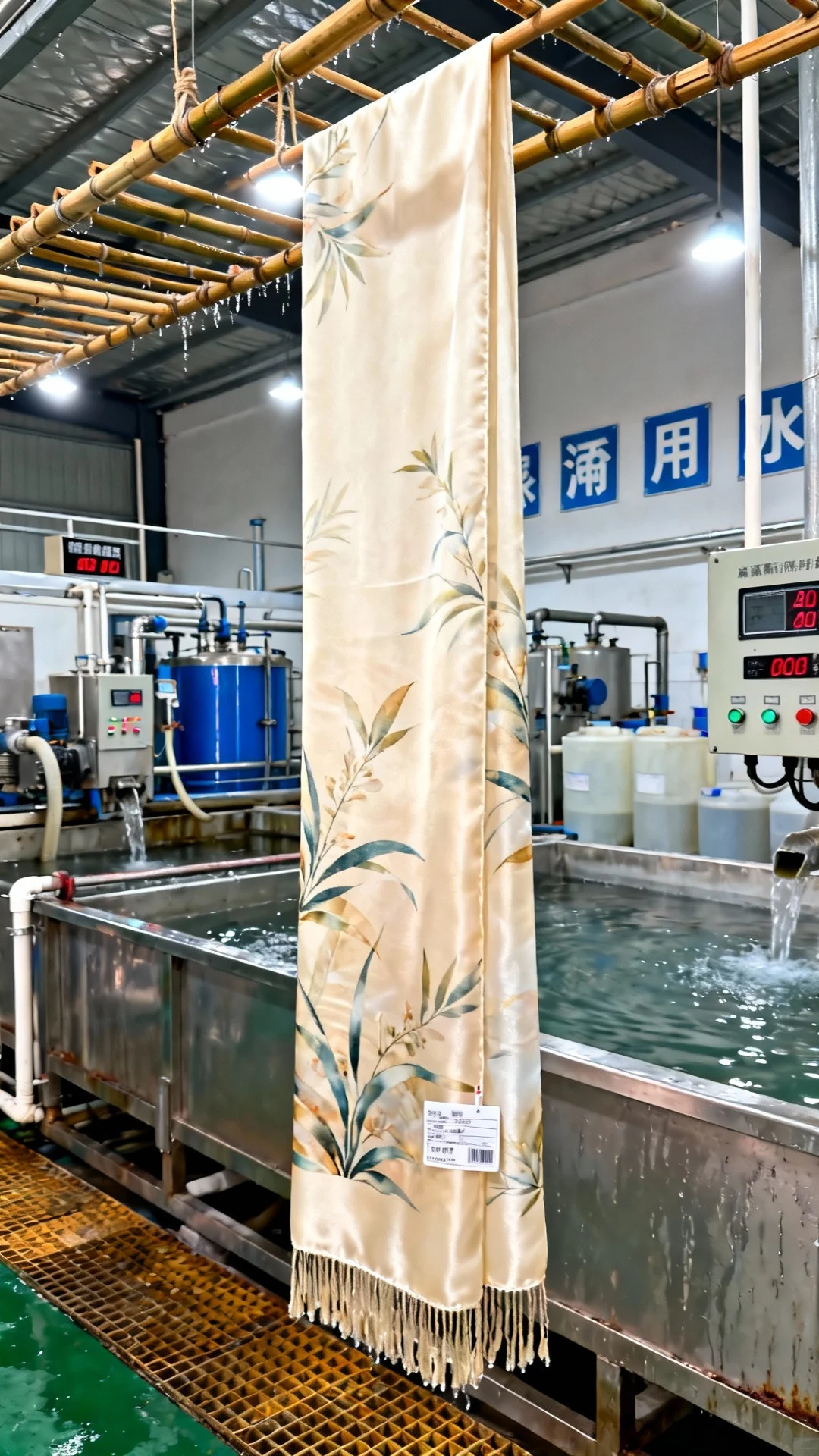

Digital textile printing fundamentally transforms scarf production with significantly lower environmental impact. Unlike traditional screen printing, which requires physical screens for each color and design element, digital printing utilizes computer-controlled inkjet technology to apply color directly to fabric with precision and minimal waste—creating substantial sustainability benefits throughout the manufacturing process.

One of the most compelling environmental advantages of digital printing is its dramatic water reduction. Industry studies consistently demonstrate that digital printing consumes up to 95% less water than conventional methods. For a medium-sized scarf manufacturer producing 50,000 pieces annually, this technology could save over 10 million liters of water each year. The Epson and Patternity collaborative scarf project in early 2025 exemplified this potential, utilizing digital printing for a limited-edition collection and conserving approximately 35,000 liters compared to traditional production methods.

Digital printing also significantly reduces textile waste through precise color application and minimal overspray. The technology enables economically viable on-demand production models, allowing manufacturers to produce smaller batches aligned with actual demand rather than speculative forecasts. Luxury accessories brand Printful documented a 40% reduction in material waste after implementing digital printing for their scarf line, saving approximately 2.3 tons of textile annually.

Energy consumption represents another area where digital printing offers environmental advantages. Modern systems incorporate advanced energy efficiency features, including heat recovery and low-power modes. Compared to the energy-intensive drying processes required for traditional screen printing inks, digital printing reduces energy usage by 30-40% per production run—lowering carbon emissions while reducing operational costs.

Most importantly, digital printing facilitates the practical application of eco-friendly inks. Water-based pigment inks have become industry standard in digital textile printing, offering low environmental impact while performing exceptionally well with natural fibers common in scarves. These inks contain fewer volatile organic compounds (VOCs) and hazardous substances, reducing worker exposure risks and environmental contamination. Leading ink manufacturers including Sun Chemical and Huntsman have developed specialized digital printing inks with enhanced sustainability profiles, with select formulations meeting strict Global Organic Textile Standard (GOTS) requirements.

Sustainable Materials in Digital Scarf Printing

Digital printing's environmental benefits are amplified when paired with sustainable materials, creating a comprehensive approach to eco-friendly scarf production. Material selection represents a critical decision point for manufacturers committed to reducing environmental footprint, as different fibers and substrates vary dramatically in resource requirements, biodegradability, and ecological impact.

Natural fibers currently lead sustainable scarf production, with organic cotton, peace silk, and recycled wool dominating the market. Organic cotton cultivation eliminates harmful pesticides and synthetic fertilizers, reducing water consumption by up to 91% compared to conventional cotton while eliminating toxic chemical runoff. Peace silk production avoids boiling silkworm cocoons, offering an animal-friendly alternative that maintains the luxurious drape and texture essential to high-end scarves. Recycled wool, sourced from post-consumer textile waste and factory offcuts, diverts material from landfills while reducing the environmental impact of virgin wool production—including methane emissions from sheep farming and water pollution from wool scouring processes.

Innovative textiles offer promising new sustainable options. Tencel™ Lyocell, produced from sustainably harvested wood pulp using a closed-loop process, delivers exceptional softness and moisture-wicking properties while recovering and reusing over 99% of solvents and water during production. Piñatex® utilizes pineapple leaf fibers that would otherwise become agricultural waste, providing a vegan alternative to leather and suede for structured scarf designs without requiring additional water, pesticides, or fertilizers beyond standard pineapple cultivation.

Recycled synthetic materials also play a valuable role in sustainable scarf production, particularly for performance designs. Recycled polyester, primarily sourced from post-consumer plastic bottles, reduces reliance on petroleum-based raw materials while diverting plastic from oceans and landfills. When processed correctly, recycled polyester maintains the durability and versatility of virgin polyester while reducing carbon footprint by approximately 70%, offering scarf manufacturers an eco-friendly option for weather-resistant designs or structural elements.

The compatibility between sustainable materials and digital printing creates powerful synergies for eco-friendly production. Digital systems effectively process many natural and recycled fibers without the heavy chemical pre-treatments required for traditional printing, expanding design possibilities for sustainable scarves. Manufacturers can achieve intricate patterns and vibrant colors on environmentally responsible substrates, with water-based digital inks bonding effectively with organic cotton and Tencel™ to produce crisp designs with excellent colorfastness that meet luxury consumers' durability expectations.

Material certification systems provide essential guidance for manufacturers and consumers alike. Certifications including GOTS (Global Organic Textile Standard), Fair Trade, and OEKO-TEX® Standard 100 verify environmental and ethical practices across supply chains. For scarf manufacturers utilizing digital printing, these certifications enhance credibility for sustainability claims while reassuring increasingly discerning customers. A 2025 market analysis confirmed scarves with recognized sustainability certifications command average price premiums of 22% in the luxury accessories market, demonstrating the commercial value of transparent eco-friendly practices.

Implementation and Best Practices

Successful sustainable digital printing for scarves requires more than technological investment—it demands a comprehensive approach encompassing equipment selection, process optimization, workflow integration, and quality control. For fashion brands and manufacturers transitioning from conventional methods, implementing best practices throughout production is essential for realizing the full environmental and economic benefits of digital printing.

Equipment selection establishes the foundation of a sustainable operation. Modern digital textile printers vary significantly in environmental performance, with newer models offering substantial improvements in energy efficiency, ink utilization, and waste reduction. When evaluating systems, manufacturers should prioritize printers featuring variable dot printing technology to optimize ink usage based on design requirements, energy management systems that power down components during production pauses, and compatibility with water-based inks—generally offering lower environmental impact than solvent-based alternatives. Leading manufacturers including Mimaki, Epson, and Kornit offer models specifically engineered for sustainable textile production, with select systems meeting stringent energy efficiency standards such as ENERGY STAR.

Process optimization maximizes sustainability gains. Prepress workflow software enables precise color management and design optimization to minimize ink usage without compromising visual quality, while robust color management systems maintain consistency across production runs to reduce waste from color mismatches and reprints. Nesting software that efficiently arranges multiple scarf designs on a single fabric panel can reduce material waste by up to 15%. For custom or limited-edition scarves, integrated digital workflow systems connect design software with production planning tools, eliminating redundant steps and reducing errors.

Drying and curing processes present significant opportunities for sustainability optimization. Traditional textile printing often relies on high-temperature ovens consuming substantial energy, while newer digital systems utilize advanced drying technologies that reduce energy consumption while improving efficiency. Infrared and ultraviolet curing systems dry inks at lower temperatures and faster than conventional methods, while waste heat recovery systems capture and reuse energy from drying processes to further reduce energy consumption by 20-30%.

Quality control protocols must adapt to digital printing's unique characteristics. Automated inspection systems identify defects early in production, minimizing waste from flawed products, while digital printing's short production runs enable more frequent quality checks without significant productivity losses. For scarves, where visual perfection is paramount, high-resolution inspection systems detect subtle color variations and print imperfections that might otherwise compromise product quality.

Workflow integration presents both challenges and opportunities. For manufacturers utilizing both conventional and digital methods, establishing clear process selection criteria is essential: digital printing excels with short runs, custom designs, and complex patterns, while traditional methods may offer economic advantages for very large production quantities of simple designs. A hybrid strategy matching each order to the optimal process maximizes overall sustainability while integrating digital printing with on-demand production models to reduce inventory and waste from overproduction—aligning with circular economy principles.

Case studies from early adopters offer valuable implementation insights. Luxury scarf manufacturer FENNYSUN's transition to digital printing demonstrates best practices in action, utilizing a phased implementation approach beginning with custom and limited-edition lines before expanding capabilities. By investing in color management systems and staff training, FENNYSUN maintained its reputation for exceptional print quality while reducing water consumption by 85% and material waste by 30% compared to traditional methods. The company further leveraged digital printing's design flexibility to create intricate patterns using fewer colors, reducing ink usage without compromising aesthetic appeal.

Another implementation example comes from a mid-sized scarf manufacturer that integrated a complete digital workflow, connecting design software, production planning, and inventory management systems. This digital transformation eliminated redundant steps, reduced errors, and eliminated nearly all paper documentation while enabling digital sampling that saved approximately 2,500 meters of fabric annually—material that would have been used for physical samples in traditional development processes. These examples demonstrate that sustainable digital printing requires coordinated investment in technology, processes, and personnel development, but delivers substantial environmental and operational benefits for forward-thinking scarf manufacturers.

Future Trends and Industry Impact

Digital printing technology and sustainability innovations will reshape scarf manufacturing over the next decade, driven by technological advancement, evolving consumer expectations, and increasing regulatory focus. As the industry accelerates toward eco-friendly practices, several emerging trends will define sustainable scarf production and competitive dynamics in the accessories market.

Technological innovation in digital printing continues at a rapid pace, with several developments promising enhanced sustainability. Advances in inkjet technology enable higher resolution with reduced ink consumption, creating more detailed designs while minimizing material use. Nanotechnology in ink formulation produces pigments that bond with fabrics at lower temperatures, reducing the environmental impact of curing processes. Most significantly, bio-based inks derived from renewable resources are expanding sustainability possibilities, with major chemical companies announcing plant-based ink formulations that reduce petroleum dependency by up to 70% while offering improved performance characteristics including enhanced color fastness and durability.

Smart technology and data analytics are transforming sustainable scarf production. Internet of Things (IoT) sensors on digital printing equipment monitor resource usage in real-time, identifying inefficiencies and enabling predictive maintenance to prevent wasteful downtime. Artificial intelligence optimizes designs to minimize ink usage without compromising visual impact—with AI software capable of identifying areas where color density can be reduced without noticeable effect, potentially cutting ink usage by 10-15%. Blockchain technology enhances supply chain transparency, enabling scarf manufacturers to trace materials from origin to finished product and verify sustainability claims with unprecedented accuracy.

Consumer demand for transparency is fundamentally changing how sustainable production is communicated and verified. QR codes on product labels provide detailed information about a scarf's manufacturing process, material origins, and environmental footprint, while some luxury brands have implemented digital passport systems documenting a product's entire lifecycle—including water and energy consumption during production. This transparency builds consumer trust while creating incentives for continuous sustainability improvement, with third-party certification growing in importance as standards like GOTS and the Sustainable Apparel Coalition's Higg Index provide objective measures of environmental performance.

Widespread digital printing adoption will transform industry dynamics, particularly benefiting small and medium-sized manufacturers. Digital technology lowers barriers to sustainable production by reducing minimum order quantities and setup costs, enabling smaller players to compete with larger manufacturers on eco-friendly credentials. This democratization of sustainable manufacturing could increase diversity in the scarf market, allowing more niche brands and artisanal producers to offer environmentally responsible products. Digital printing also enables localization—producing closer to consumer markets—which could significantly reduce the carbon footprint from transportation and logistics in the scarf supply chain.

Industry forecasts suggest digital printing could capture up to 40% of the global scarf printing market by 2030 if current growth trends continue. This transition would conserve over 20 billion liters of water annually and reduce textile waste by approximately 1.2 million tons per year. The economic impact is equally significant: sustainable digital printing could create $8.3 billion in new market opportunities within the luxury accessories segment by 2028. For fashion brands and manufacturers willing to invest in sustainable digital printing technology and processes, the future looks both environmentally responsible and commercially promising.

Conclusion: The Sustainable Path Forward

Digital printing technology and sustainable manufacturing practices offer the scarf industry a transformative opportunity to address pressing environmental challenges while meeting evolving consumer demands. As we've explored, digital printing delivers substantial environmental benefits across multiple dimensions: dramatically reducing water consumption, minimizing material waste, improving energy efficiency, and eliminating toxic chemicals. When combined with eco-friendly materials and responsible production practices, these technological advancements create a comprehensive framework for sustainable scarf manufacturing that aligns environmental stewardship with commercial success.

The environmental case for digital printing in scarf production has never been stronger. The metrics are clear: water savings of up to 95% compared to traditional methods, energy consumption reduced by 30-40%, and textile waste cut by 15-40% through on-demand production models. For an industry segment historically criticized for resource intensity, these improvements represent a profound shift toward sustainability. Initiatives like the Epson-Patternity collaboration demonstrate this potential perfectly, utilizing digital printing to create visually striking scarves while highlighting and addressing fashion's water consumption challenges—reducing environmental impact while engaging consumers in important sustainability conversations.

From a business perspective, sustainable digital printing presents a compelling value proposition. Consumer demand for eco-friendly accessories accelerates constantly, with 2025 market research indicating sustainability credentials influence over 70% of luxury scarf purchasing decisions. This trend manifests in growing price premiums—averaging 22%—for sustainable products. Digital printing further delivers operational advantages including reduced inventory costs, faster time-to-market, and greater design flexibility, creating value beyond environmental considerations. For boutique owners and specialty retailers serving discerning customers, partnering with manufacturers utilizing sustainable digital printing provides a distinct competitive advantage in an increasingly crowded market.

Looking ahead, sustainable digital printing for scarf production holds tremendous promise but requires ongoing commitment from all industry stakeholders. Technology developers must continue innovating to improve efficiency and reduce costs. Manufacturers need to invest in training and process optimization to maximize sustainability gains. Brands have a critical role to play in educating consumers about environmental impacts and verification standards. Together, these efforts can transform the scarf manufacturing industry into a model of sustainable production—demonstrating that environmental responsibility and commercial success can flourish together.

The path forward is clear: digital printing technology has matured to deliver both exceptional quality and substantial sustainability benefits, creating a new paradigm for scarf manufacturing that honors both artistic expression and environmental stewardship. For industry professionals navigating this evolving landscape, embracing these sustainable technologies represents not just ethical leadership, but sound business strategy in an increasingly eco-conscious marketplace.