As a seasoned textile sourcing specialist with over a decade in luxury accessory quality assurance, I've witnessed firsthand how material authenticity directly impacts brand reputation and customer satisfaction. In today's market, where counterfeit luxury scarves have become increasingly sophisticated, the ability to accurately identify premium materials is more critical than ever for boutique owners, fashion brands, and procurement professionals alike.

This comprehensive guide integrates 2025 industry standards, cutting-edge material science advancements, and field-tested authentication techniques to navigate the complex landscape of luxury scarf sourcing. Whether evaluating potential suppliers or authenticating existing inventory, these insights will empower you to make informed decisions that protect your brand integrity and satisfy the most discerning clientele.

The Fundamentals of Luxury Scarf Materials

At the heart of any exceptional luxury scarf lies its material composition. While the textile market offers a vast array of options, cashmere and silk remain the undisputed gold standards for luxury scarf production in 2025. Each material possesses distinct characteristics that demand specific evaluation approaches.

Cashmere: The Diamond Fiber

Revered as the "diamond fiber" of the textile world, cashmere dominates the luxury scarf market due to its exceptional softness, insulating properties, and remarkable durability. The 2025 Good Cashmere Standard (GCS) 2.0 has refined quality benchmarks with precise fiber classification parameters that professionals must understand.

Premium cashmere scarves should utilize Grade A fibers measuring 14-15 microns in diameter—approximately one-fifth the thickness of a human hair—and with a minimum length of 34mm. These ultra-fine fibers create fabrics that feel incredibly soft against the skin while maintaining structural integrity through multiple seasons of wear and care.

Silk: The Epitome of Elegance

Silk, particularly mulberry silk, represents the pinnacle for warm-weather and decorative scarves. The most sought-after varieties include:

- Charmeuse: Renowned for its luminous drape and smooth handfeel

- Crepe de Chine: Valued for its subtle texture and excellent drape characteristics

- Georgette: Prized for its lightweight, airy quality with a distinctive slight crinkle

The highest grades of silk feature uniform thread thickness, consistent color absorption, and minimal slubs or imperfections.

Industry data from 2025 indicates growing demand for blended luxury materials, with cashmere-silk and wool-silk combinations gaining significant traction. These blends offer enhanced durability and versatility, allowing designers to create scarves that maintain premium characteristics while offering improved performance attributes like reduced pilling or increased wrinkle resistance. When evaluating blends, professionals should focus on luxury fiber percentage—authentic luxury scarves typically contain at least 70% pure cashmere or silk to justify their premium pricing.

Advanced Cashmere Authentication Techniques

Authenticating cashmere requires a systematic approach that engages multiple senses and often incorporates specialized testing methodologies. The tactile test remains your first line of defense—genuine cashmere feels exceptionally soft with a distinctive "buttery" texture that synthetic imitations struggle to replicate. When running the fabric between your fingers, high-quality cashmere should glide smoothly without any prickling sensation, which typically indicates the presence of coarser guard hairs or synthetic fibers.

The Compression Test

This simple yet effective test reveals much about cashmere quality. Gently squeeze a section of the scarf in your fist and release—premium cashmere should quickly recover its shape without creasing, thanks to the natural elasticity of its fine fibers. Inferior cashmere or blends will tend to stay wrinkled and may show permanent compression signs.

Microscopic Fiber Analysis

For scientific assessment, microscopic fiber analysis provides definitive results. Under 100x+ magnification, authentic cashmere fibers appear irregularly shaped with overlapping scales. In contrast, synthetic imitations typically feature uniform, smooth cylindrical fibers. Many luxury brands and certification bodies now utilize AI-powered fiber analysis tools that can identify material composition with over 99% accuracy—a technology that has become increasingly accessible to quality control departments in 2025.

The Burn Test

While somewhat destructive, the burn test offers conclusive proof when performed correctly. Extract a few threads from an inconspicuous area and carefully ignite them with a lighter. Pure cashmere burns slowly with a smell similar to burning hair, leaving behind a brittle, ash-like residue that crumbles easily. Synthetic fibers, by comparison, will melt, drip, produce chemical odors, and leave hard, plastic-like beads that resist crushing.

When evaluating supplier cashmere scarves, always request detailed fiber analysis reports and certification documentation. The Good Cashmere Standard (GCS) 2.0—mandatory since 2025—provides comprehensive guidelines for sustainable sourcing and quality assurance, including strict animal welfare standards and traceability requirements. Reputable suppliers should readily provide GCS certification along with ISO/DIS 22786 compliance documentation specifying rigorous management practices for cashmere goat breeding and fiber collection.

Silk Quality Assessment Protocol

Silk authentication requires a discerning eye for detail and a thorough understanding of the properties that distinguish premium varieties from imitations. Begin your visual inspection in natural light—a genuine silk scarf will exhibit a characteristic luster that changes subtly at different angles, known as "peau de soie" (skin of silk). This optical phenomenon occurs because silk fibers have triangular cross-sections that reflect light differently depending on the viewing angle—an effect that synthetic fabrics with cylindrical fibers cannot replicate.

Texture Evaluation

Texture evaluation reveals important quality indicators. Run your hand across the scarf surface with light pressure—high-quality silk should feel smooth yet略带 resistance, a property known as "drag." This subtle friction comes from microscopic ridges on silk fibers catching slightly on the skin, creating a distinctive tactile experience that differs from the slippery feel of polyester satin or rayon.

The Water Test

The water test provides valuable insights into silk authenticity. Place a small water drop on an inconspicuous area—genuine silk absorbs water slowly, forming a spreading circle without immediate penetration. The wet area will darken temporarily and dry without water spots, thanks to silk's natural protein structure. Synthetic imitations will either repel water initially or absorb it rapidly, often leaving visible watermarks after drying.

Understanding Silk Grades

For professionals evaluating silk scarves, understanding different silk grades is essential. Grade 6A represents the highest quality, referring to mulberry silk fibers measuring 6A thickness (approximately 11-12 microns) and at least 36mm in length. These exceptional fibers produce scarves with unparalleled softness, drape, and durability. Lower grades (5A, 4A, etc.) feature progressively shorter and thicker fibers, which reduce both quality and performance.

When assessing printed silk scarves—a category showing significant 2025 growth according to market reports—closely examine color penetration and edge definition. Premium printing ensures color saturation through the entire fiber cross-section, not just a surface coating. Run your finger across printed areas; genuine quality will show consistent color intensity without rubbing off, while inferior printing may leave color residue on the skin. High-resolution designs should also exhibit sharp edges without blurring—a sign of advanced digital printing technology and proper color calibration.

Sustainable Sourcing: Certifications and Ethical Considerations

The 2025 luxury scarf market features a profound shift toward sustainability, with environmental and ethical considerations now ranking among the top criteria for fashion professionals selecting suppliers. As consumer awareness grows, brands that prioritize sustainable sourcing demonstrate corporate responsibility while gaining a competitive advantage in an increasingly discerning marketplace.

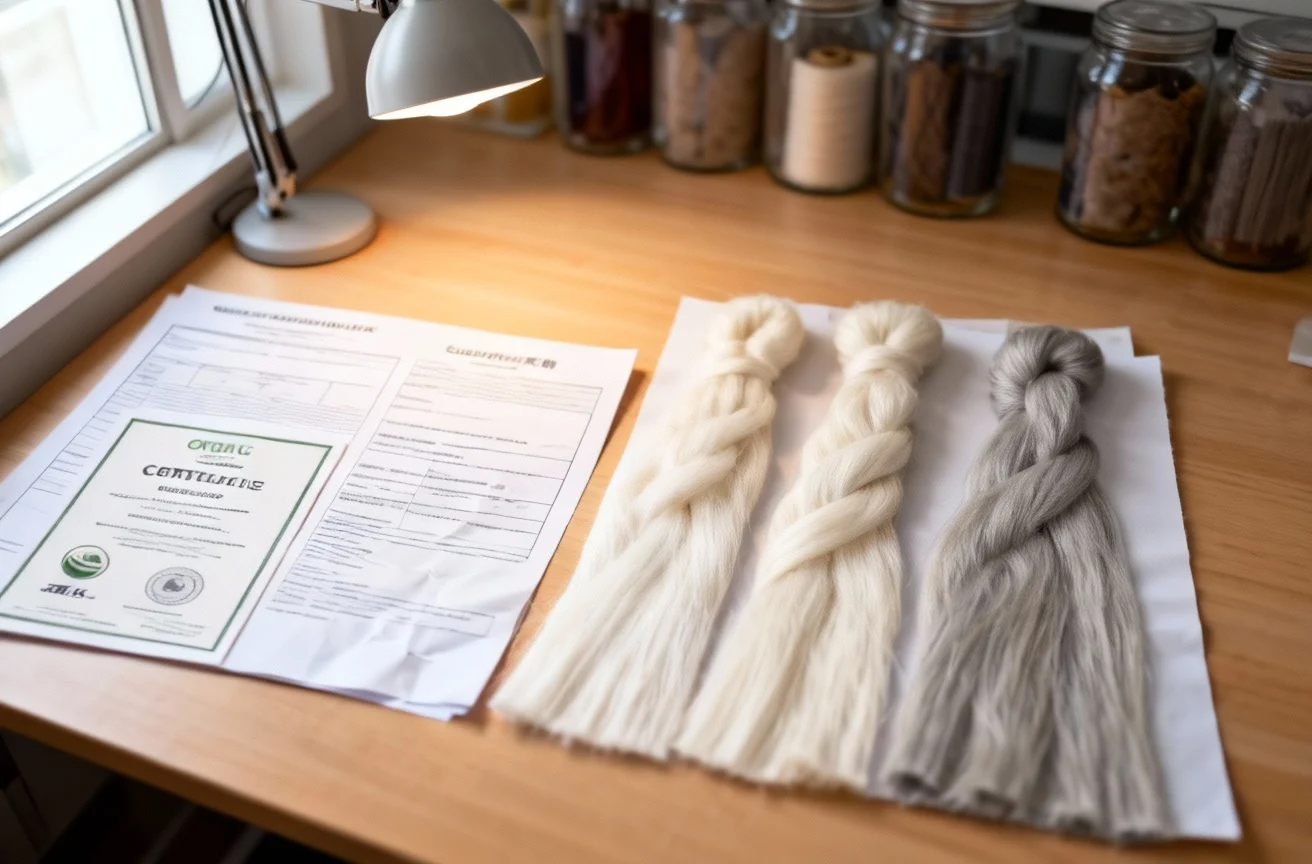

Essential Certification Verification

Certification verification has become the cornerstone of sustainable fabric sourcing. Key certifications include:

- Global Organic Textile Standard (GOTS): Remains the most comprehensive certification for organic textiles, covering the entire supply chain from fiber production to finished product. GOTS certification ensures textiles contain at least 70% organic fibers, with strict limits on chemical inputs, wastewater treatment, and social responsibility.

- Responsible Wool Standard (RWS): Originally developed for wool, now adapted for cashmere. It provides assurance that fibers come from humanely treated animals raised on farms with sound environmental practices.

- OEKO-TEX® Standard 100: Essential for textile safety, testing for harmful substances beyond legal requirements. For luxury scarves in direct skin contact, look for Class I certification—the highest standard suitable for baby products and the most sensitive applications.

Blockchain Technology and Supply Chain Transparency

Beyond certification labels, progressive fashion brands now use blockchain technology to enhance supply chain transparency. This innovation allows buyers to trace a scarf's journey from fiber source to finished product, verifying sustainability claims with unprecedented accuracy. When evaluating suppliers, ask about their traceability systems—forward-thinking manufacturers increasingly provide digital passports documenting each production stage, including fiber origin, processing facilities, and transportation methods.

Innovative Textile Technologies

Sustainable sourcing also includes innovative textile technologies transforming the industry in 2025. Biodegradable finishes, natural dyeing with plant-based pigments, and waterless printing technologies are no longer experimental but mainstream practices among leading luxury scarf producers. These advancements reduce environmental impact while often creating superior product quality and unique aesthetic characteristics appealing to discerning consumers.

Supplier Evaluation Framework: Selecting Premium Scarf Manufacturers

Selecting the right scarf supplier critically impacts product quality, brand reputation, and bottom-line performance. In today's competitive luxury market, systematic supplier evaluation has become essential for fashion professionals seeking reliable, long-term partnerships with manufacturers delivering consistently exceptional products.

Production Capacity Assessment

Production capacity assessment goes beyond verifying the ability to meet order quantities. It involves evaluating production processes, technology investments, and quality control systems. Request detailed information about manufacturing facilities, including equipment specifications, workforce expertise, and quality assurance protocols. Leading 2025 manufacturers have invested heavily in advanced technologies: digital printing with eco-friendly inks, automated quality inspection systems, and sustainable production methods that minimize waste and energy consumption.

Material Sourcing Transparency

Material sourcing transparency has emerged as a non-negotiable criterion for luxury scarf buyers. Reputable suppliers should provide comprehensive documentation on fiber origins, including authenticity certificates for premium materials like Grade A cashmere and 6A mulberry silk. They should also demonstrate compliance with international sustainability standards through recognized certifications.

Quality Control Procedures

Quality control procedures deserve meticulous attention during supplier evaluation. Inquire about sampling protocols, inspection frequencies, and defect classification systems. Top manufacturers implement multiple quality checkpoints throughout production—from incoming material inspection to final product approval. They should also have documented procedures for handling non-conforming products and continuous improvement initiatives based on quality metrics.

Lead Time Reliability and Ethical Manufacturing

Lead time reliability directly impacts inventory management and time-to-market for seasonal collections. Evaluate suppliers on historical on-time delivery performance, flexibility for rush orders, and communication systems for production updates.

Ethical manufacturing practices have become integral to luxury sector supplier evaluation. Assess suppliers on labor practices, workplace safety standards, and commitment to fair compensation. Look for certifications verifying compliance with rigorous social responsibility criteria.

Practical Implementation: Building Your Material Authentication Protocol

Translating theoretical knowledge into practical quality assurance procedures is essential for fashion professionals evaluating luxury scarf materials. Developing standardized authentication protocols ensures team consistency and provides clear guidelines for assessing new suppliers and incoming inventory.

Essential Material Testing Kit

Begin by establishing a material testing kit for your quality control team. This specialized toolkit should include:

- 100x magnification lens for fiber inspection

- Small scale for weight-per-unit-area measurements

- pH testing strips for dye acidity evaluation

- Precision ruler for measuring fabric density

- Portable spectrophotometer for colorfastness verification

Standard Operating Procedures

Develop a standard operating procedure (SOP) document outlining step-by-step authentication protocols for each material type. For cashmere scarves, include specific criteria for fiber diameter, crimp frequency, and weight. For silk evaluations, include procedures testing moisture absorption rates, light reflectivity patterns, and thermal conductivity—all objective measures distinguishing genuine silk from synthetic alternatives.

Sampling Strategy and Supplier Qualification Tiers

Implement a sampling strategy ensuring representative evaluation of each production lot. Textile industry standard requires sampling at least 3% of scarves from each shipment, with a minimum of five units even for small batches.

Establish supplier qualification tiers based on consistent performance metrics. Tier 1 suppliers are strategic partners consistently meeting the highest quality standards, while Tier 2 suppliers meet all quality requirements but may lack Tier 1 innovation or flexibility. Tier 3 suppliers require increased oversight.

By implementing the comprehensive framework outlined in this guide, fashion professionals can confidently navigate the complex landscape of luxury scarf sourcing and authentication. The ability to accurately identify premium cashmere and silk materials not only protects brand reputation but also ensures customer satisfaction in an increasingly competitive marketplace.