In today's competitive luxury fashion accessories market, maintaining impeccable quality standards is not merely advantageous—it's imperative. As a textile manufacturing professional with over a decade of industry experience, I've witnessed firsthand how quality control challenges can directly impact brand reputation and bottom-line profitability. This case study examines how FENNYSUN, a leading luxury scarf manufacturer, successfully implemented advanced digital quality control systems to reduce defect rates by 40%—establishing new industry benchmarks for manufacturing excellence and setting a precedent for quality control automation in textiles.

The Unique Quality Control Challenges in Luxury Scarf Manufacturing

Luxury scarves, particularly those crafted from premium materials such as cashmere, silk, and fine wool blends, present distinct quality control challenges that demand specialized solutions. The combination of intricate patterns, delicate fabrics, and precise manufacturing processes requires meticulous inspection protocols to ensure flawless finished products. While traditional manual inspection methods can be thorough, they are inherently limited by human factors—including fatigue, subjectivity, and speed constraints—that often result in inconsistent quality checks and missed defects.

Industry research indicates that quality control issues typically account for 15-20% of total production costs in scarf manufacturing. Defective products translate directly to customer returns, brand damage, and lost revenue. For high-end manufacturers, these costs escalate dramatically due to the premium materials involved and the exceptionally high expectations of discerning clientele. According to a 2025 Luxury Fashion Quality Report, accessories brands with consistent quality issues face return rates up to 40% higher than their peers, accompanied by significant reputational damage in an industry where perfection is the baseline expectation.

The Digital Quality Control Technology Framework

FENNYSUN addressed these persistent challenges by implementing a comprehensive digital quality control framework that integrates multiple advanced technologies into a cohesive quality assurance ecosystem:

AI-Powered Visual Inspection Systems

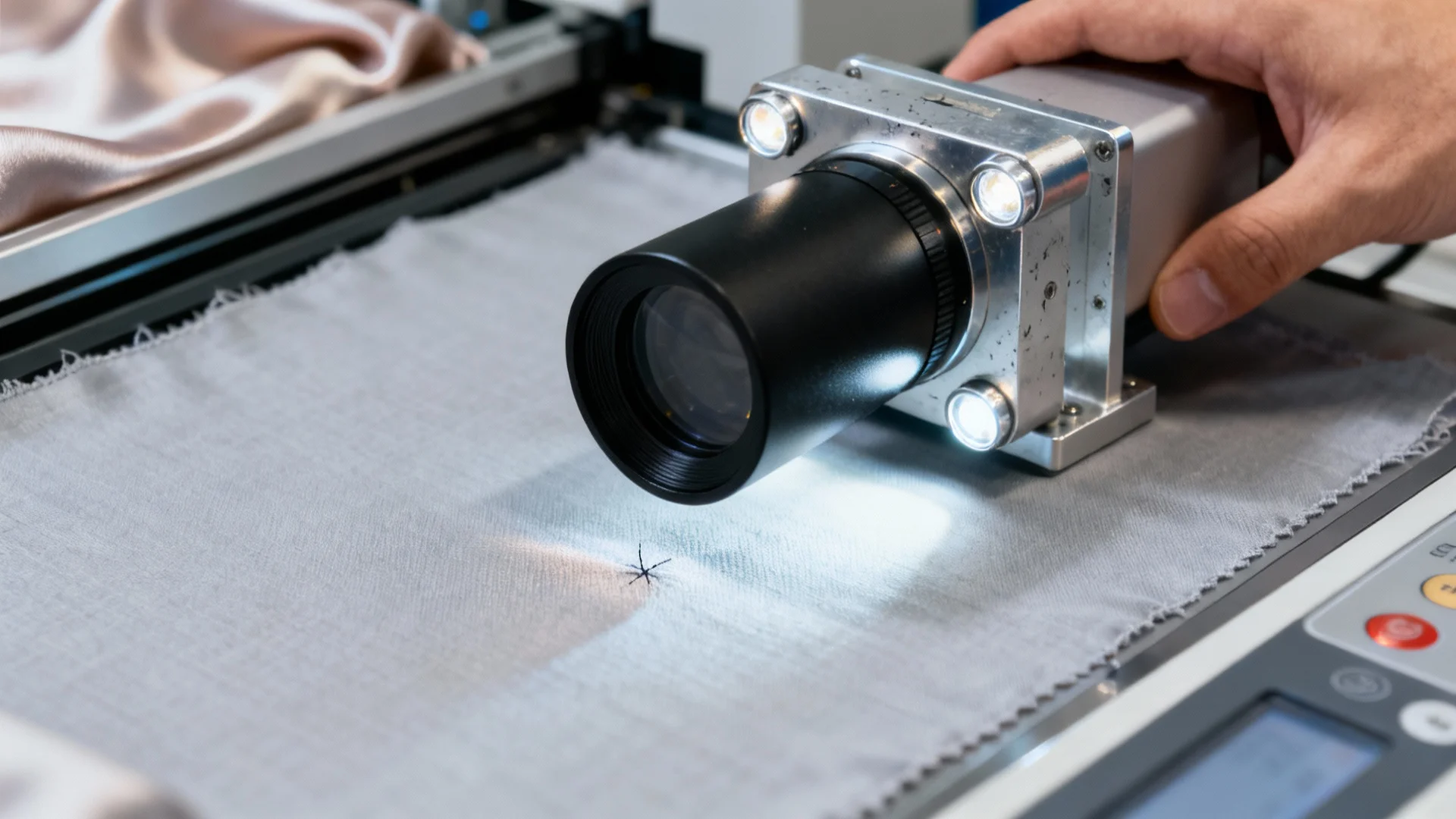

At the core of this transformation lies AI-powered visual inspection systems capable of analyzing scarf surfaces at resolutions exceeding standard industry capabilities. These sophisticated systems utilize high-resolution cameras capturing up to 12K imagery, enabling the detection of defects as small as 0.1mm—far beyond the visual acuity of even the most experienced human inspectors.

The AI models powering these systems were meticulously trained on thousands of annotated scarf images representing the complete spectrum of potential defect types:

- Thread irregularities and broken fibers

- Printing inconsistencies and color variations

- Weaving defects including dropped stitches and tension issues

- Edge and hemming imperfections

- Contamination and foreign particles

Real-Time Process Monitoring

Complementing the visual inspection technology, FENNYSUN installed IoT-enabled sensors throughout its production lines to continuously monitor critical environmental conditions and equipment performance metrics. This real-time data collection capability enables proactive identification of potential quality issues before they manifest in finished products.

Cloud-Based Quality Management Platform

All inspection data flows into a centralized cloud-based quality management platform, providing quality control teams with actionable insights through intuitive interfaces. The platform features customizable dashboards, automated defect classification, and advanced trend analysis tools that pinpoint recurring issues and their root causes—transforming raw data into strategic quality improvement opportunities.

Strategic Implementation Process and Methodology

Recognizing the importance of minimizing production disruption while maximizing technology adoption, FENNYSUN employed a structured, phased implementation approach:

Phase 1: Assessment and Planning (8 weeks)

- Comprehensive audit of existing quality control processes and pain points

- Detailed identification and categorization of critical defect types with impact analysis

- Technology selection based on specific scarf manufacturing requirements and material characteristics

- Development of detailed implementation roadmap with clear success metrics and milestones

Phase 2: System Integration (12 weeks)

- Strategic installation of visual inspection hardware at key production stages

- Seamless integration with existing manufacturing execution systems

- Development and training of specialized AI models calibrated for specific scarf materials

- Implementation of IoT sensor network and robust data collection infrastructure

Phase 3: Testing and Optimization (6 weeks)

- Parallel operation of manual and automated inspection systems for comparison

- Continuous calibration of AI models using real-world production data

- Fine-tuning of inspection parameters for different scarf materials and patterns

- Comprehensive training program for quality control personnel on new systems and workflows

Phase 4: Full Deployment (Ongoing)

- Gradual transition to automated inspection as the primary quality control method

- Continuous monitoring of system performance and defect detection accuracy

- Regular updates to AI models to address emerging defect patterns

- Strategic expansion of system capabilities to additional product lines

Measured Results and Performance Metrics

The implementation yielded substantial improvements across multiple quality control metrics, validating the investment in textile testing technology:

Defect Detection and Reduction

The most significant achievement was a 40% reduction in overall defect rates within six months of full system deployment. Results varied by defect category:

- 52% reduction in printing-related defects

- 47% reduction in weaving irregularities

- 38% reduction in edge finishing issues

- 35% reduction in material contamination defects

Operational Efficiency Improvements

Beyond defect reduction, the digital quality control system delivered substantial operational benefits:

- 65% reduction in manual inspection labor costs

- 30% increase in inspection throughput without compromising accuracy

- 75% reduction in human error-related defects

- 92% accuracy rate in defect classification and categorization

Quality Assurance ROI

The investment in digital quality control technology demonstrated clear and measurable return on investment:

- 28% reduction in quality-related costs

- 35% decrease in customer returns for quality issues

- 22% improvement in on-time delivery rates

- Significant reduction in waste material and production rework

Implementation Challenges and Strategic Solutions

Despite the overall success, several implementation challenges emerged, each addressed with targeted solutions:

Material Variability Issues

Challenge: The wide range of materials used in FENNYSUN's production—including cashmere, silk, wool blends, and specialty fabrics—exhibited varying visual characteristics that initially confused the AI systems.

Solution: Development of material-specific inspection parameters and separate AI model training for each primary material type, resulting in 95%+ accuracy rates across all materials within the testing phase.

Integration with Legacy Equipment

Challenge: Several existing production machines lacked modern digital interfaces required for seamless system integration.

Solution: Implementation of retrofitted sensor packages and custom middleware solutions to enable bidirectional data exchange between legacy equipment and the new quality control platform, preserving existing capital investments while gaining digital capabilities.

Operator Adoption Resistance

Challenge: Initial resistance from quality control personnel concerned about technology potentially replacing their roles.

Solution: Comprehensive change management program emphasizing the transition from manual inspection to technology supervision and exception handling, reframing roles rather than eliminating them. This included upskilling opportunities and the creation of new quality analyst positions focused on data interpretation and continuous improvement.

Practical Recommendations for Implementation

Based on FENNYSUN's experience, several key recommendations emerge for luxury scarf manufacturers considering implementing digital quality control systems:

Prioritize Critical Quality Control Points

Begin implementation at production stages with the highest defect rates or where defects most significantly impact product quality and customer perception.

Invest in Material-Specific AI Training

Allocate sufficient resources for training AI models on your specific production materials and patterns to ensure optimal defect detection accuracy across your product range.

Develop a Phased Implementation Plan

Avoid operational disruption by implementing new systems gradually, allowing for thorough testing and optimization before full deployment across all production lines.

Focus on Data Integration and Analysis Capabilities

Ensure the quality control system integrates with other production management systems for a comprehensive quality view across the entire manufacturing process.

Establish Clear Success Metrics Before Implementation

Define specific, measurable goals for defect reduction, efficiency improvements, and return on investment to objectively evaluate implementation success and identify areas for further optimization.

Future Directions in Textile Quality Control Technology

Looking ahead, FENNYSUN continues to innovate its quality control processes with emerging technologies on the horizon:

Advanced 3D Surface Mapping

Implementation of cutting-edge 3D scanning technology to detect subtle surface irregularities invisible to conventional 2D inspection systems, particularly valuable for textured and patterned scarf designs.

Predictive Quality Analytics

Expansion of AI capabilities to predict potential quality issues before they occur, enabling proactive process adjustments and minimizing waste.

Augmented Reality Quality Verification

Development of AR tools that overlay digital inspection data onto physical scarves during final quality checks, enhancing the capabilities of human quality assurance specialists.

Blockchain-Enabled Quality Documentation

Exploration of blockchain technology to create immutable quality inspection records, enhancing transparency for customers and supply chain partners while providing valuable product provenance information.

Conclusion: Transforming Quality Control in Luxury Textiles

FENNYSUN's implementation of digital quality control represents a significant advancement in luxury scarf manufacturing, demonstrating how technology can solve longstanding quality control challenges while delivering substantial business benefits. The 40% defect rate reduction not only improved product quality and customer satisfaction but also created measurable operational efficiencies and cost savings across the production process.

For fashion brands and manufacturers considering quality control enhancements, the key takeaways include:

- Digital quality control technologies offer capabilities that far exceed traditional manual inspection methods

- Successful implementation requires careful planning, phased deployment, and ongoing optimization

- The technology represents a strategic investment with clear return on investment through defect reduction and operational efficiency gains

- Successful adoption involves both technological integration and workforce transition management

As the luxury textile industry continues to evolve, digital quality control automation will increasingly become a standard differentiator between market leaders and followers. Early adopters like FENNYSUN are gaining significant competitive advantage through superior product quality, enhanced operational efficiency, and stronger customer trust—positioning themselves for sustained success in an increasingly demanding marketplace. The future of textile quality control is digital, and the transformation has already begun.